主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2025, Vol. 46 ›› Issue (3): 240117-.doi: 10.12382/bgxb.2024.0117

收稿日期:2024-02-22

上线日期:2025-03-26

通讯作者:

基金资助:Received:2024-02-22

Online:2025-03-26

摘要:

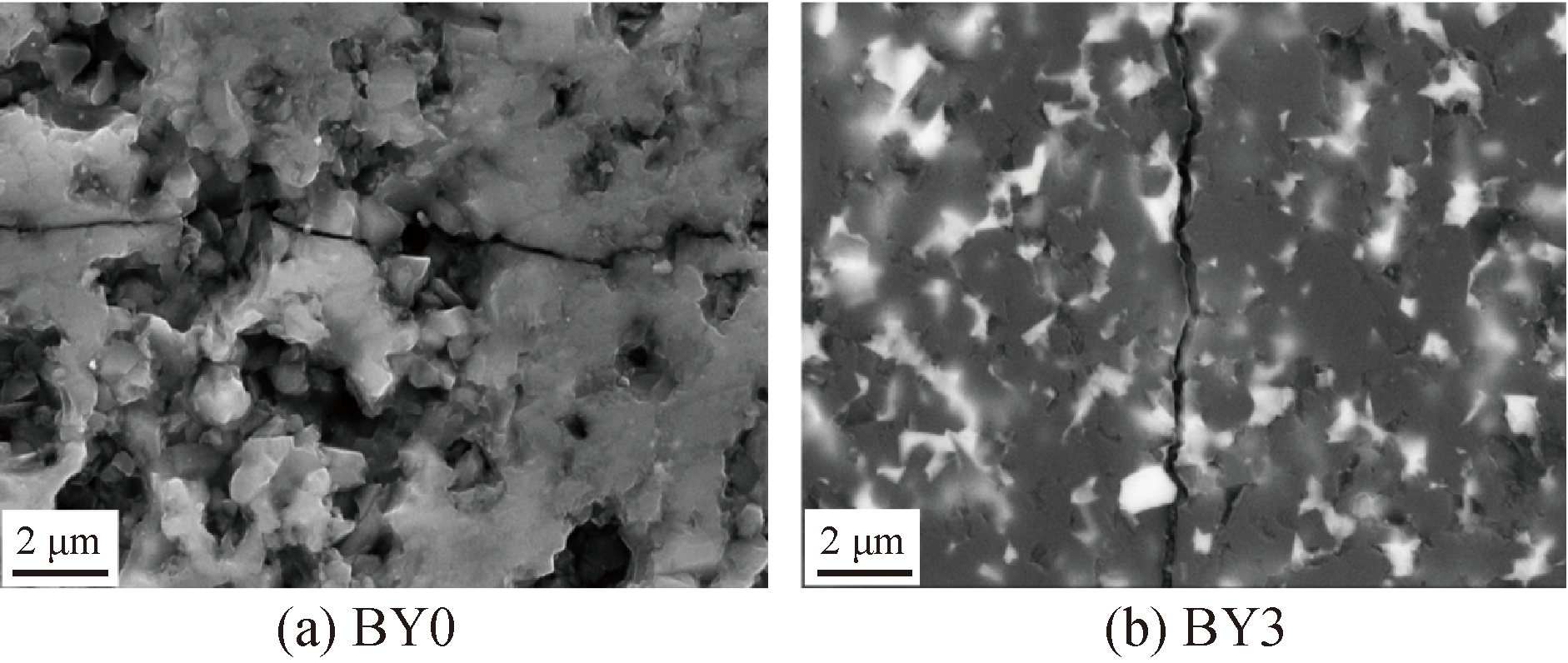

为了研究烧结助剂Y3Al5O12对热压烧结制备的B4C陶瓷的影响,以B4C微粉为原料,以Al2O3+Y2O3原位反应生成的Y3Al5O12为烧结助剂,在1950℃烧结温度下,采用热压烧结工艺制备出B4C陶瓷,研究Y3Al5O12添加量对B4C陶瓷物相组成、烧结性能、微观结构和力学性能的影响。研究结果表明:当烧结助剂Y3Al5O12添加量<7wt.%时,B4C陶瓷中晶界以B4C-B4C晶粒相连接的清洁晶界和B4C-非晶相Y3Al5O12-B4C晶界2种形式存在;当烧结助剂Y3Al5O12添加量≥7wt.%时,B4C陶瓷中晶界以B4C-B4C晶粒相连接的清洁晶界、B4C-非晶相Y3Al5O12-B4C晶界和B4C-晶相Y3Al5O12-B4C晶界3种形式存在;当Y3Al5O12添加量为7wt.%时,热压烧结B4C陶瓷的综合性能最佳,即相对密度为96.2%,硬度为20.9GPa,抗弯强度为455MPa,断裂韧性为3.53MPa·m1/2;烧结助剂Y3Al5O12通过改变热压烧结B4C陶瓷的气孔率、晶粒尺寸和晶界特征影响B4C陶瓷的力学性能。

中图分类号:

张巍, 张杰. Y3Al5O12对热压烧结B4C陶瓷微观组织及力学性能的影响[J]. 兵工学报, 2025, 46(3): 240117-.

ZHANG Wei, ZHANG Jie. Effect of Y3Al5O12 on Microstructure and Mechanical Properties of B4C Ceramics Prepared by Hot-press Sintering[J]. Acta Armamentarii, 2025, 46(3): 240117-.

| 编号 | B4C | Al2O3+Y2O3 |

|---|---|---|

| BY0 | 100 | 0 |

| BY1 | 97 | 3 |

| BY2 | 95 | 5 |

| BY3 | 93 | 7 |

| BY4 | 91 | 9 |

表1 含有不同添加量烧结助剂Y3Al5O12的B4C陶瓷成分

Table 1 Composition of B4C ceramics with different contents of Y3Al5O12 sintering additive wt.%

| 编号 | B4C | Al2O3+Y2O3 |

|---|---|---|

| BY0 | 100 | 0 |

| BY1 | 97 | 3 |

| BY2 | 95 | 5 |

| BY3 | 93 | 7 |

| BY4 | 91 | 9 |

| 编号 | B4C晶粒尺寸/μm |

|---|---|

| BY0 | 0.90 |

| BY1 | 0.81 |

| BY2 | 0.79 |

| BY3 | 0.80 |

| BY4 | 1.07 |

表2 含有不同添加量烧结助剂Y3Al5O12的B4C陶瓷的晶粒尺寸

Table 2 Grain sizes of B4C ceramics with different contents of Y3Al5O12 sintering additive

| 编号 | B4C晶粒尺寸/μm |

|---|---|

| BY0 | 0.90 |

| BY1 | 0.81 |

| BY2 | 0.79 |

| BY3 | 0.80 |

| BY4 | 1.07 |

图8 含有不同添加量烧结助剂Y3Al5O12的B4C陶瓷的维氏硬度、抗弯强度和断裂韧性

Fig.8 Vickers hardness,bending strength,and fracture toughness of B4C ceramics with different contents of Y3Al5O12 sintering additive

图10 含有不同添加量烧结助剂Y3Al5O12的B4C陶瓷抛光表面的裂纹扩展

Fig.10 Propagation of cracks on the polished surfaces of B4C ceramics with different contents of Y3Al5O12 sintering additive

| [1] |

黄明, 曹峰, 彭志航, 等. 防弹装甲用碳化硼陶瓷材料的研究进展[J]. 现代技术陶瓷, 2021, 42(4):213-224.

|

|

|

|

| [2] |

魏汝斌, 董彬, 王小伟, 等. 人体防护装备用碳化硼抗弹陶瓷应用探析[J]. 兵工学报, 2022, 43(9):2210-2218.

|

|

doi: 10.12382/bgxb.2022.0478 |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

张志倩, 赵太勇, 于寅业, 等. 穿甲弹垂直侵彻陶瓷复合靶弹道极限速度的研究[J]. 火炮发射与控制学报, 2021, 42(1):36-42.

|

|

|

|

| [7] |

|

| [8] |

张天星, 余毅磊, 蒋招绣, 等. 薄板氧化铝陶瓷复合装甲抗侵彻行为规律研究[J]. 兵器材料科学与工程, 2022, 45(4):24-28.

|

|

|

|

| [9] |

|

| [10] |

张巍, 张杰. B4C-Al2O3复合陶瓷的增韧机理[J]. 材料研究学报, 2024, 38(8):614-620.

doi: 10.11901/1005.3093.2023.521 |

|

doi: 10.11901/1005.3093.2023.521 |

|

| [11] |

|

| [12] |

郭健, 梁森, 黄浩杰, 等. 一种新型高性能抗冲击防弹陶瓷的组分及烧结工艺研究[J]. 兵器装备工程学报, 2023, 44(10):17-24.

|

|

|

|

| [13] |

|

| [14] |

张巍. B4C-SiC复合陶瓷力学性能的研究进展[J]. 复合材料学报, 2025, 42(1):88-103.

|

|

|

|

| [15] |

|

| [16] |

张巍, 张杰. 烧结助剂种类对B4C陶瓷摩擦学性能的影响[J]. 材料热处理学报, 2024, 45(6):220-228.

|

|

|

|

| [17] |

张巍, 张杰. 碳化硼陶瓷自润滑研究现状[J]. 中国表面工程, 2024, 37(3):103-114.

|

|

|

|

| [18] |

|

| [19] |

|

| [20] |

石小磊, 张聪, 谭毅, 等. B4C-SiC复相陶瓷的制备与性能[J]. 机械工程材料, 2009, 33(12):77-80.

|

|

|

|

| [21] |

朱保鑫, 张玉军, 岳双双, 等. 热压烧结制备高致密度B4C陶瓷及其致密化[J]. 现代技术陶瓷, 2013, 34(6):7-11.

|

|

|

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

赵义亮, 黄楠, 茹红强, 等. 烧结助剂Al2O3-Y2O3添加量对无压液相烧结TiC陶瓷结构与性能的影响[J]. 机械工程材料, 2022, 46(11):55-59.

doi: 10.11973/jxgccl202211009 |

|

|

|

| [26] |

黄新平, 李漠, 吕宝军, 等. Y2O3-Al2O3对热压复合陶瓷Si3N4/(W,Ti)C性能及组织的影响[J]. 机械工程材料, 2004, 28(8):15-17.

|

|

|

|

| [27] |

|

| [28] |

史秀梅, 崔红, 曹剑武, 等. Al2O3/Y2O3复合助剂对常压烧结B4C陶瓷性能的影响[J]. 兵器材料科学与工程, 2017, 40(1):62-65.

|

|

|

|

| [29] |

陈威, 郝文慧, 高东强, 等. 烧结温度对B4C基复合陶瓷的组织及物理力学性能的影响[J]. 超硬材料工程, 2020, 32(6):35-40.

|

|

|

|

| [30] |

张泳昌, 周立娟, 吴炳辉, 等. Al2O3/Y2O3复合助剂对碳化硅蜂窝陶瓷烧结性能的影响研究[J]. 人工晶体学报, 2015, 44(5):1330-1335.

|

|

|

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

|

| [35] |

|

| [36] |

张希晨. h-BN/Y-Al-Si-O复相陶瓷的组织结构和力学及抗热震性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2022.

|

|

|

|

| [37] |

|

| [38] |

|

| [39] |

|

| [40] |

|

| [1] | 杨帆, 秦子尚, 李达诚, 胡兆财, 解维华, 孟松鹤. 布立冈型螺旋纤维仿生复合材料动静态力学行为[J]. 兵工学报, 2025, 46(2): 240118-. |

| [2] | 马立, 范霁康, 张建, 从保强, 杨东青, 彭勇, 王克鸿. 超音频脉冲电流叠加对高氮钢GMA增材制造组织性能的影响[J]. 兵工学报, 2025, 46(1): 231097-. |

| [3] | 李祥辉, 张兴渝, 胡家豪, 刘洋, 马伯翰, 王永刚, 蒋招绣. AISI 4340钢靶大塑性模型及断裂起始模型参数研究[J]. 兵工学报, 2025, 46(1): 231210-. |

| [4] | 高茂国, 刘睿, 郭岩松, 耿恒恒, 陈鹏万. HfZrTiTaAl系高熵合金动态变形、损伤及破坏行为[J]. 兵工学报, 2025, 46(1): 231183-. |

| [5] | 徐跃跃, 张向荣, 高家乐, 刘战伟, 苗飞超, 刘攀, 周霖. DNP基熔铸炸药的力学性能和失效准则[J]. 兵工学报, 2024, 45(9): 3114-3124. |

| [6] | 王逸凡, 李永鹏, 徐豫新, 刘铁磊, 焦晓龙, 王若素. 钨球对碳纤维增强复合材料包覆碳化硼陶瓷侵彻效应[J]. 兵工学报, 2024, 45(8): 2487-2496. |

| [7] | 曹路晴, 乔扬, 谢晶, 陈鹏万. 石墨烯气凝胶的压缩力学性能研究[J]. 兵工学报, 2024, 45(7): 2364-2373. |

| [8] | 韩瑞, 李晓鹏, 彭勇, 闫德俊, 王克鸿. SiCp/2024Al复合材料热挤压对激光焊接接头组织性能的影响[J]. 兵工学报, 2024, 45(6): 2054-2064. |

| [9] | 项新梅, 罗林林, 符祖书, 何世珠. 梯度模式对Miura-ori超材料力学性能影响的研究[J]. 兵工学报, 2024, 45(2): 618-627. |

| [10] | 董理赢, 谭向龙, 吴艳青, 杨昆. 新型GAP/RDX/TEGDN推进剂宽应变率下的力学性能及模型参数标定[J]. 兵工学报, 2024, 45(12): 4517-4529. |

| [11] | 胡敖博, 赵超越, 陈进, 陈鹏, 李鹏, 孙兴昀, 蔡水洲. Zr基BMG-W含能破片的力学性能与毁伤性能[J]. 兵工学报, 2024, 45(12): 4407-4422. |

| [12] | 徐浩然, 温垚珂, 董方栋, 覃彬, 沈鲁豫. SEBS凝胶的创伤弹道特性[J]. 兵工学报, 2024, 45(11): 4071-4080. |

| [13] | 李一凡, 付佳维, 杨雕, 李延泽. 某大口径火炮内膛结构对挤进过程身管内壁载荷的影响[J]. 兵工学报, 2024, 45(11): 4106-4118. |

| [14] | 袁璟, 蔺向阳, 彭洋, 檀成. 光固化含能粘合剂的设计与合成[J]. 兵工学报, 2023, 44(7): 2023-2032. |

| [15] | 杜雨田, 许泽建, 虎宏智, 黄风雷. 金属材料动态剪切测试方法[J]. 兵工学报, 2023, 44(5): 1502-1512. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4