主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2025, Vol. 46 ›› Issue (10): 250499-.doi: 10.12382/bgxb.2025.0499

收稿日期:2025-06-12

上线日期:2025-11-05

通讯作者:

基金资助:

LING Jing, LIANG Yanxiang, JING Lin*( )

)

Received:2025-06-12

Online:2025-11-05

摘要:

以具有抗冲击应用潜力的亚稳态面心立方晶格(Face-Centered Cubic,FCC)/体心立方晶格(Body-Centered Cubic,BCC)双相Al15(CoCrFeNi)85高熵合金为研究对象,旨在系统研究其动态压缩力学行为并揭示微观变形机制。采用万能试验机、霍普金森压杆、电子背散射衍射、分子动力学模拟研究了其静动态压缩力学性能,分析了其塑性应力-应变响应特性、应变率敏感性及微观变形机制,阐明了其动态压缩强化机理,建立了其动态压缩本构模型。结果表明,动态压缩加载下该合金表现出明显应变率强化效应,且流动应力随应变先缓慢增长后显著上升;初始微观结构为FCC(71.4%)/BCC(28.6%)双相结构,单轴压缩加载下发生FCC相向BCC相转变,且受应变率影响较大,准静态压缩下FCC相与BCC相比值约为1∶1,动态下约为3∶7,该相变直接导致流动应力突变;MD模拟进一步证实了应变率效应显著,塑性变形机制以相变主导,且随BCC相增多由全位错滑移主导BCC相变形;基于Johnson-Cook模型,建立了亚稳态双相Al15(CoCrFeNi)85合金动态压缩本构模型。本研究为其在抗冲击结构材料设计与应用提供了重要理论依据。

中图分类号:

凌静, 梁延祥, 敬霖. Al15(CoCrFeNi)85高熵合金的动态冲击力学响应与变形机制[J]. 兵工学报, 2025, 46(10): 250499-.

LING Jing, LIANG Yanxiang, JING Lin. Dynamic Impact Mechanics Response and Deformation Mechanisms of Al15(CoCrFeNi)85 High-entropy Alloy[J]. Acta Armamentarii, 2025, 46(10): 250499-.

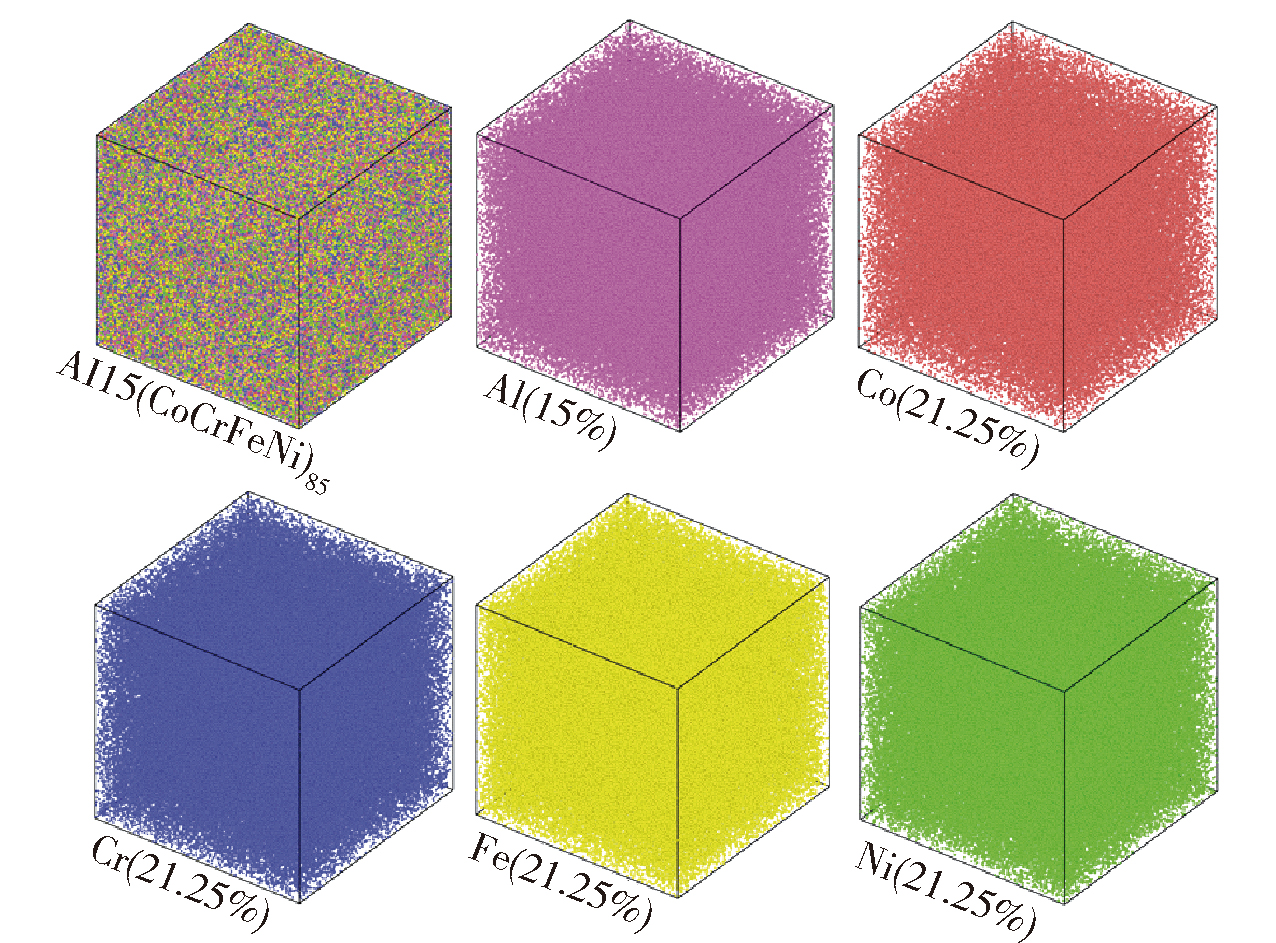

图2 单晶Al15(CoCrFeNi)85合金的分子动力学模拟模型示意图

Fig.2 Schematic diagram of molecular dynamics simulation model for single-crystal Al15(CoCrFeNi)85 high-entropy alloy

图5 不同应变率下Al15(CoCrFeNi)85高熵合金的取向与局部应变分布

Fig.5 Orientation and local strain distribution of Al15(CoCrFeNi)85 high-entropy alloy at different strain rates

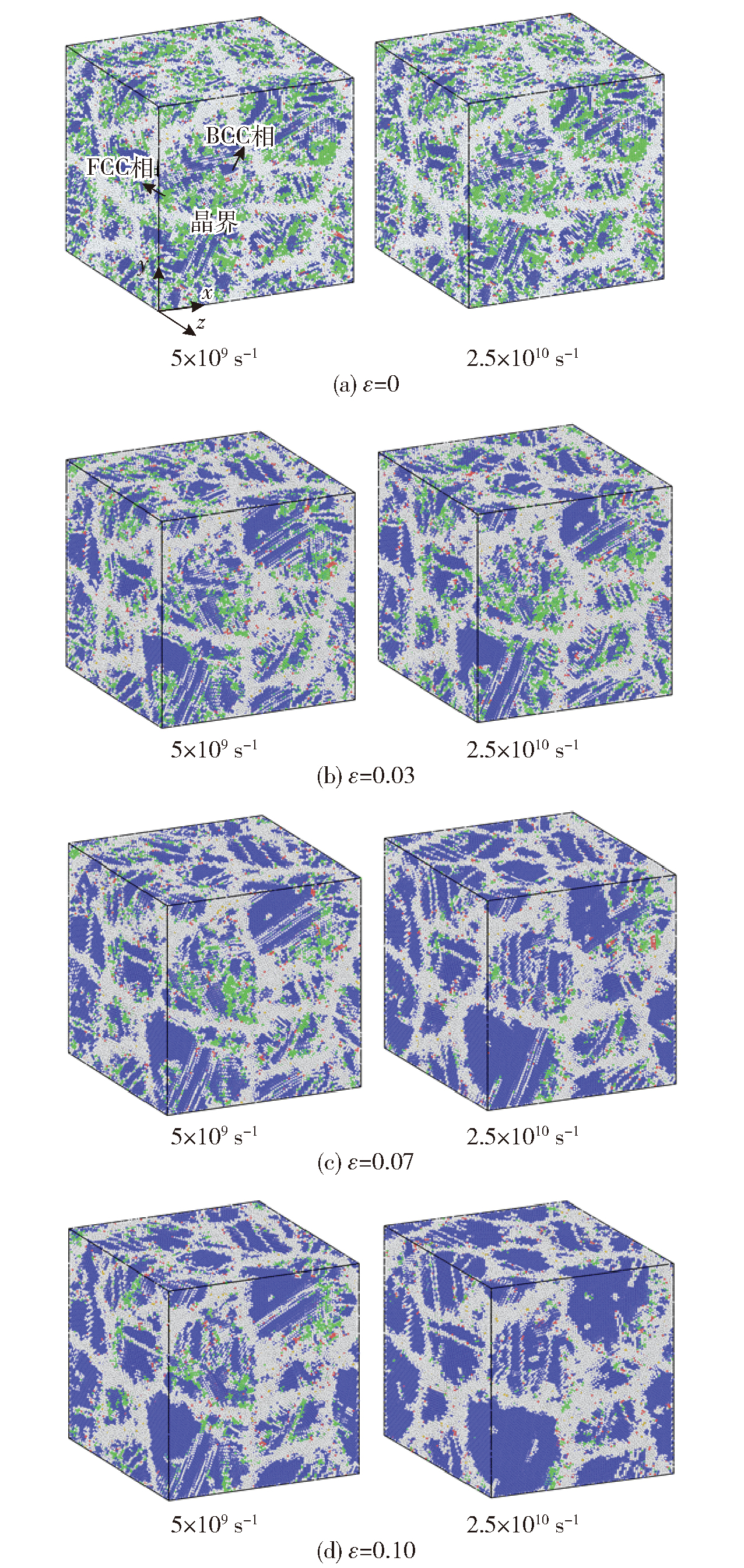

图8 不同应变率下Al15(CoCrFeNi)85高熵合金微观组织随应变的原子快照图

Fig.8 Atomic snapshots of microstructural evolution in Al15(CoCrFeNi)85 high-entropy alloy at different strain rates

图9 不同应变率下Al15(CoCrFeNi)85高熵合金模型中不同晶格原子比例随应变的变化曲线

Fig.9 Lattice atom ratio versus strain in Al15(CoCrFeNi)85 high-entropy alloy models at different strain rates

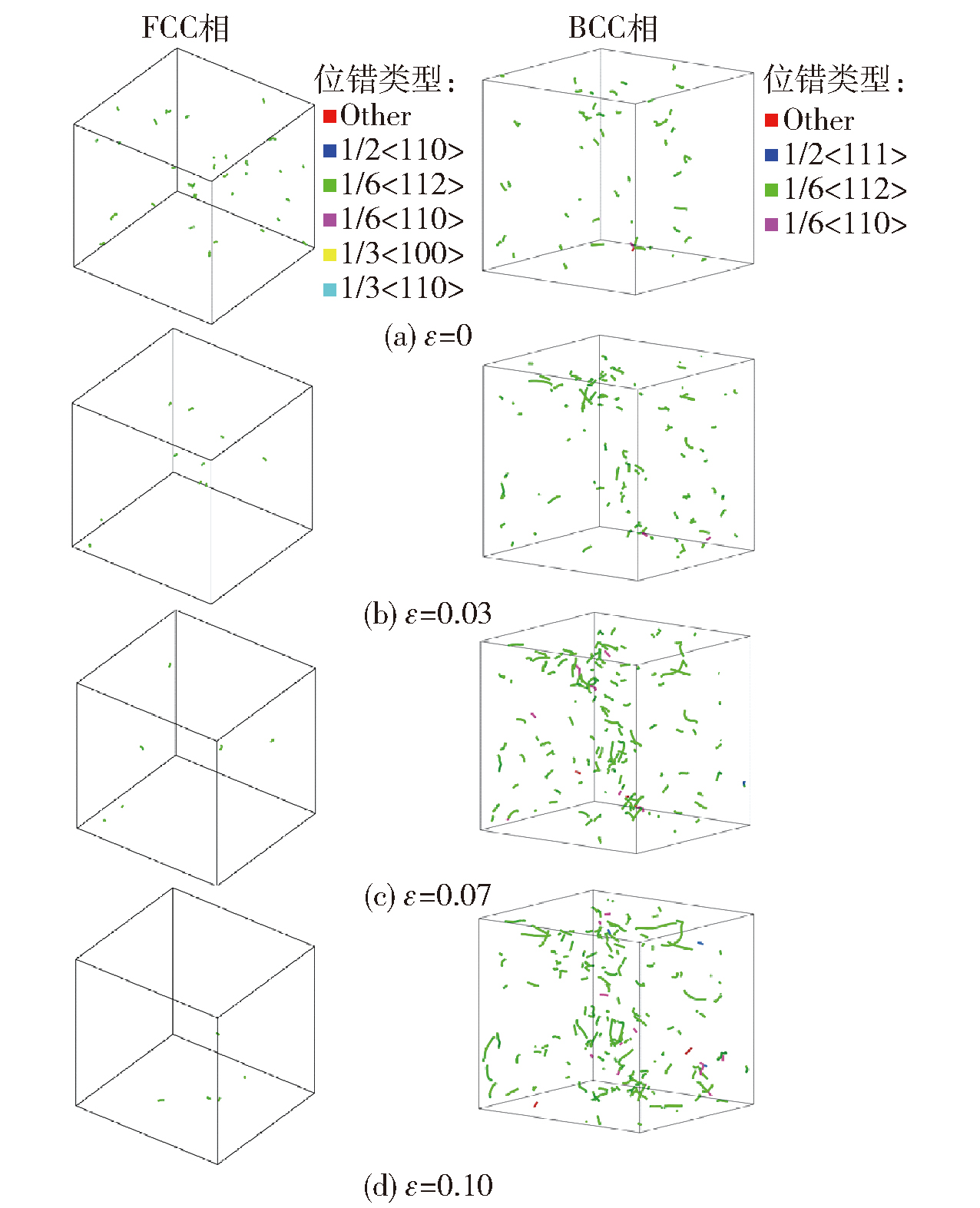

图10 5×109s-1压缩加载下Al15(CoCrFeNi)85高熵合金高熵合金不同相中的位错演化

Fig.10 Dislocation evolution in different phases of Al15(CoCrFeNi)85 high-entropy alloy under compressive loading at 5×109s-1

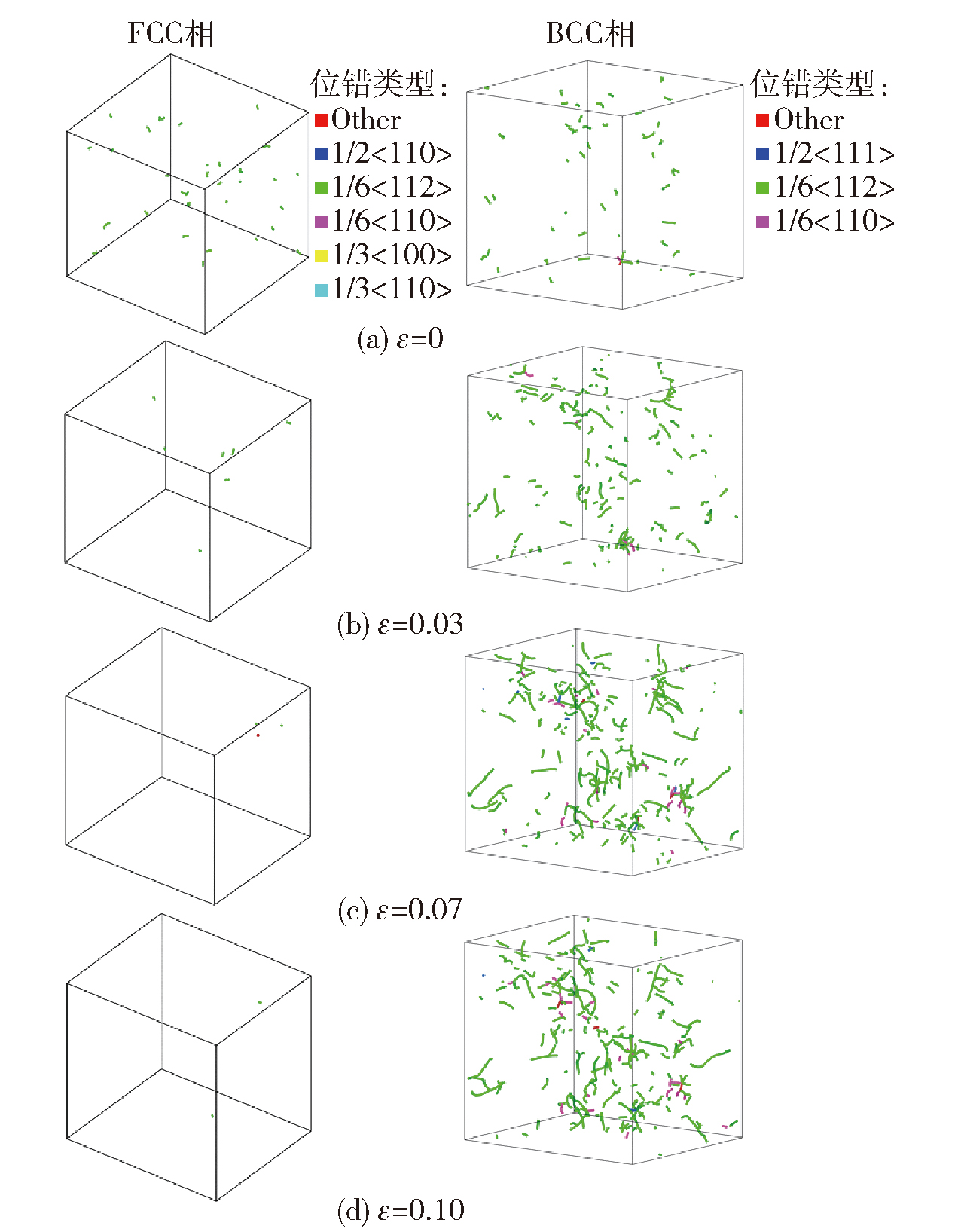

图11 2.5×1010s-1压缩加载下Al15(CoCrFeNi)85高熵合金不同相中的位错演化

Fig.11 Dislocation evolution in different phases of Al15(CoCrFeNi)85 high-entropy alloy under compressive loading at 2.5×1010s-1

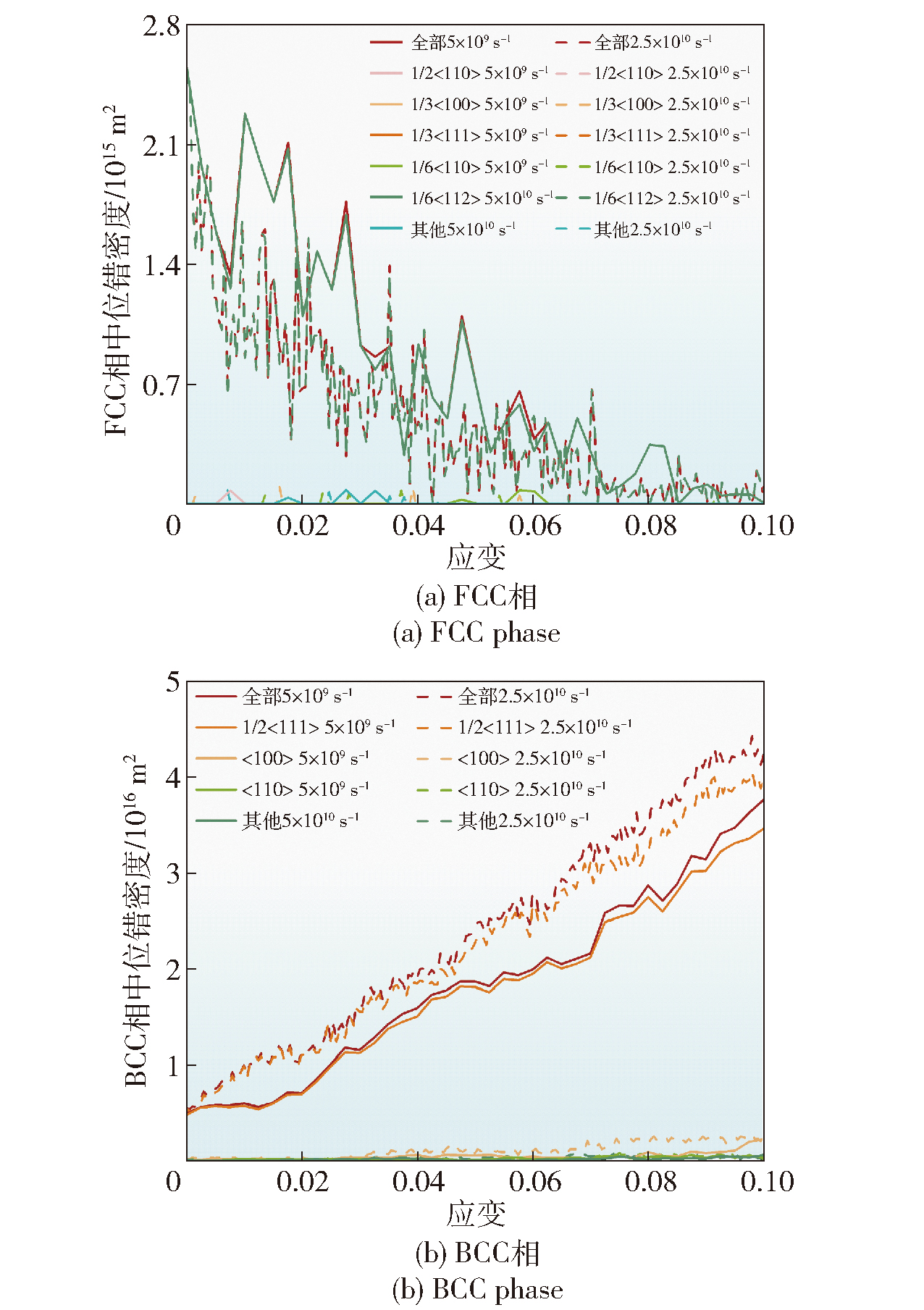

图12 不同应变率下Al15(CoCrFeNi)85高熵合金FCC相和BCC相中位错密度与应变的关系

Fig.12 Dislocation density-strain relationship of Al15(CoCrFeNi)85 high-entropy alloy at different strain rates

图13 应变率敏感性系数C与无量纲应变率${\stackrel{·}{\epsilon }}^{*}$的关系

Fig.13 Relationship between thestrain rate sensitivity coefficient C and the dimensionless strain rate ${\stackrel{·}{\epsilon }}^{*}$

图14 不同应变率下 Al15(CoCrFeNi)85高熵合金压缩应力-应变响应实验数据与模型预测比较

Fig.14 Comparison between model predicted and experimental compressive stress-strain responses of Al15(CoCrFeNi)85 high-entropy alloy at different train rates

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

高茂国, 刘睿, 郭岩松, 等. HfZrTiTaAl系高熵合金动态变形、损伤及破坏行为[J]. 兵工学报, 2025, 46(1):290-300.

|

|

|

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

|

| [27] |

|

| [28] |

敬霖, 冯超, 苏兴亚, 等. 高速动车组D2车轮钢的率温耦合变形机理与本构关系[J]. 科学通报, 2022, 67(34): 4068-4079.

|

|

|

| [1] | 王圣芳, 常慧, 焦志明, 尹云飞, 张团卫, 李志强, 王志华. 高熵合金活性破片的毁伤效应与碎片云特性[J]. 兵工学报, 2025, 46(10): 250482-. |

| [2] | 张雯雯, 赵聃, 赵伟涛, 王强, 王建军, 马胜国, 张团卫, 王志华. CoCrNi系高熵合金析出强化的晶体塑性模型:力学性能及织构演化[J]. 兵工学报, 2025, 46(10): 250110-. |

| [3] | 高茂国, 刘睿, 郭岩松, 耿恒恒, 陈鹏万. HfZrTiTaAl系高熵合金动态变形、损伤及破坏行为[J]. 兵工学报, 2025, 46(1): 231183-. |

| [4] | 刘承哲, 王海福, 张甲浩, 郑元枫. 轻质高熵合金聚能射流毁伤混凝土靶行为研究[J]. 兵工学报, 2024, 45(S1): 60-69. |

| [5] | 李一凡, 付佳维, 杨雕, 李延泽. 某大口径火炮内膛结构对挤进过程身管内壁载荷的影响[J]. 兵工学报, 2024, 45(11): 4106-4118. |

| [6] | 蒋明飞, 许辉, 黄陈磊, 刘坤, 吴志林. 弹道明胶动态力学性能试验与本构模型研究[J]. 兵工学报, 2022, 43(9): 2113-2120. |

| [7] | 张杜江, 赵振宇, 贺良, 任建伟, 强鹭升, 周贻来. 基于Johnson-Cook本构模型的高强度装甲钢动态力学性能参数标定及验证[J]. 兵工学报, 2022, 43(8): 1966-1976. |

| [8] | 李东伟, 苗飞超, 张向荣, 熊国松, 周霖, 赵双双. 2,4-二硝基苯甲醚基不敏感熔注炸药动态力学性能[J]. 兵工学报, 2021, 42(11): 2344-2349. |

| [9] | 秦金凤, 赵雪, 钱华, 芮久后. 高致密球形黑索今晶体结构对高聚物粘结炸药安全性能的影响[J]. 兵工学报, 2020, 41(3): 481-487. |

| [10] | 郭瑞奇, 任辉启, 张磊, 龙志林, 吴祥云, 徐翔云, 李泽斌, 黄魁. 分离式大直径Hopkinson杆实验技术研究进展[J]. 兵工学报, 2019, 40(7): 1518-1536. |

| [11] | 高玉波, 秦国华, 张伟, 宜晨虹, 邓勇军. TiB2-B4C复合陶瓷动态压缩特性研究[J]. 兵工学报, 2019, 40(11): 2304-2310. |

| [12] | 王严培, 姜启帆, 李玉龙. 基于Hopkinson杆试验技术的PA-GF50复合材料动态力学行为[J]. 兵工学报, 2018, 39(1): 161-169. |

| [13] | 齐晓飞, 谢五喜, 严启龙, 刘庆, 刘春. 中性聚合物键合剂与奥克托今的界面作用[J]. 兵工学报, 2017, 38(10): 1942-1949. |

| [14] | 杨冬丽, 徐正国, 杨杰, 王琳, 杨院生. 相对密度对泡沫镁合金动态力学性能的影响[J]. 兵工学报, 2013, 34(10): 1286-1290. |

| [15] | 齐晓飞1, 张晓宏1, 李吉祯1, 刘芳莉1, 宋振伟1, 张军平2. NC/NG共混体系的分子动力学模拟研究[J]. 兵工学报, 2013, 34(1): 93-99. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4