主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2025, Vol. 46 ›› Issue (1): 231193-.doi: 10.12382/bgxb.2023.1193

收稿日期:2023-12-17

上线日期:2024-03-05

通讯作者:

LIU Zhenxian, JIANG Jianwei*( ), LI Mei, XIE Hongwei

), LI Mei, XIE Hongwei

Received:2023-12-17

Online:2024-03-05

摘要:

压环是爆炸成型弹丸(Explosively Formed Projectile,EFP)装药结构中紧固装药和药型罩不可缺少的部件。为研究其在爆炸驱动过程中对药型罩形成EFP特征的影响,选取典型球缺型紫铜药型罩基准装药结构,采用有限元分析软件的拉格朗日、任意拉格朗日-欧拉、光滑粒子流法(Smooth Particle Hydrodynamics,SPH)及有限元法(Finite Element Method,FEM)-SPH自适应耦合等算法分别建模和仿真计算,对各算法计算获得的EFP速度和形态特征与脉冲X光摄影拍摄的EFP图像进行对比,采用FEM-SPH算法获得高精度的EFP成型仿真结果。针对该基准装药结构,在压环与药型罩质量比MR/ML≤0.2范围,进行矩形及非矩形压环参数(如轴向、径向厚度及截面形状)和材料对EFP初速、质量转换比、长径比和气动特性(密实度及迎风面积)参数影响的仿真计算。研究结果表明:矩形截面压环的轴向、径向厚度及材料参数对EFP初速影响在3%以内;对EFP质量转换比呈递减趋势(最大可降低12.6%);对EFP长径比呈递减趋势(最大可降低19.2%);密实度呈递增趋势,钢环较无压环,EFP的密实度提高32.6%;迎风面积呈递减趋势。以上结果表明考虑压环有利于EFP翻转成型和形成更密实的杆式EFP,并减小其迎风阻力。所得研究结果可为EFP装药结构的优化设计提供指导。

中图分类号:

刘贞娴, 蒋建伟, 李梅, 谢泓炜. 压环对爆炸成型弹丸成型影响的高精度仿真分析[J]. 兵工学报, 2025, 46(1): 231193-.

LIU Zhenxian, JIANG Jianwei, LI Mei, XIE Hongwei. High Precision Simulation of the Influence of Pressing Ring on EFP Forming Properties[J]. Acta Armamentarii, 2025, 46(1): 231193-.

| 参数 | 数值 | 参数 | 数值 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 铜 | 钢 | 铝 | 铜 | 钢 | 铝 | |||||||||

| ρ/ (g·cm-3) | 8.96 | 7.85 | 2.78 | D1 | 0.54 | 0.10 | 0.13 | |||||||

| A/MPa | 90 | 506 | 265 | D2 | 4.89 | 0.76 | 0.13 | |||||||

| B/MPa | 292 | 320 | 426 | D3 | -3.03 | 1.57 | -1.50 | |||||||

| n | 0.31 | 0.28 | 0.34 | D4 | 0.014 | 0.005 | 0.011 | |||||||

| C | 0.025 | 0.064 | 0.015 | D5 | 1.12 | -0.84 | 0 | |||||||

| m | 1.09 | 1.06 | 1.70 | |||||||||||

表1 金属材料J-C模型参数[21-22]

Table 1 J-C model parameters of liner[21-22]

| 参数 | 数值 | 参数 | 数值 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 铜 | 钢 | 铝 | 铜 | 钢 | 铝 | |||||||||

| ρ/ (g·cm-3) | 8.96 | 7.85 | 2.78 | D1 | 0.54 | 0.10 | 0.13 | |||||||

| A/MPa | 90 | 506 | 265 | D2 | 4.89 | 0.76 | 0.13 | |||||||

| B/MPa | 292 | 320 | 426 | D3 | -3.03 | 1.57 | -1.50 | |||||||

| n | 0.31 | 0.28 | 0.34 | D4 | 0.014 | 0.005 | 0.011 | |||||||

| C | 0.025 | 0.064 | 0.015 | D5 | 1.12 | -0.84 | 0 | |||||||

| m | 1.09 | 1.06 | 1.70 | |||||||||||

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| ρe/(kg·m-3) | 1.70 | R1 | 4.60 |

| pC-J/GPa | 29.50 | R2 | 1.35 |

| Ae/GPa | 854.5 | ω | 0.25 |

| Be/GPa | 20.49 | E/GPa | 8.50 |

| D/(m·s-1) | 8315 |

表2 炸药JWL状态方程模型参数[23]

Table 2 JWL model parameters ofexplosives[23]

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| ρe/(kg·m-3) | 1.70 | R1 | 4.60 |

| pC-J/GPa | 29.50 | R2 | 1.35 |

| Ae/GPa | 854.5 | ω | 0.25 |

| Be/GPa | 20.49 | E/GPa | 8.50 |

| D/(m·s-1) | 8315 |

| 药型罩/压环算法以及试验值 | 长径比 | 初速v0/(m·s-1) |

|---|---|---|

| Lagrange | 2.88 | 2072 |

| ALE | 2.80 | 2091 |

| SPH | 2.90 | 2159 |

| FEM-SPH | 3.06 | 2126 |

| Lagrange/FEM-SPH | 2.94 | 2147 |

| FEM-SPH/Lagrange | 3.09 | 2176 |

| 试验值 | 3.24 | 2120 |

表3 170μs时刻EFP参数仿真结果与测试结果对比

Table 3 Comparisonamong calculated and test results of EFP characteristic parameter values

| 药型罩/压环算法以及试验值 | 长径比 | 初速v0/(m·s-1) |

|---|---|---|

| Lagrange | 2.88 | 2072 |

| ALE | 2.80 | 2091 |

| SPH | 2.90 | 2159 |

| FEM-SPH | 3.06 | 2126 |

| Lagrange/FEM-SPH | 2.94 | 2147 |

| FEM-SPH/Lagrange | 3.09 | 2176 |

| 试验值 | 3.24 | 2120 |

| 压环材料 | ρ/(g·cm-3) | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|---|

| 钢压环 | 7.85 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

| 铝压环 | 2.78 | 2091 | 3.38 | 0.67 | 232.35 | 0.91 |

| 无压环 | 0 | 2074 | 3.61 | 0.56 | 380.13 | 0.99 |

表4 不同压环材料下EFP特征参数值(170μs时刻)

Table 4 Calculated results of characteristic parameter values of EFPs with and without pressing rings made of different materials (170μs)

| 压环材料 | ρ/(g·cm-3) | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|---|

| 钢压环 | 7.85 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

| 铝压环 | 2.78 | 2091 | 3.38 | 0.67 | 232.35 | 0.91 |

| 无压环 | 0 | 2074 | 3.61 | 0.56 | 380.13 | 0.99 |

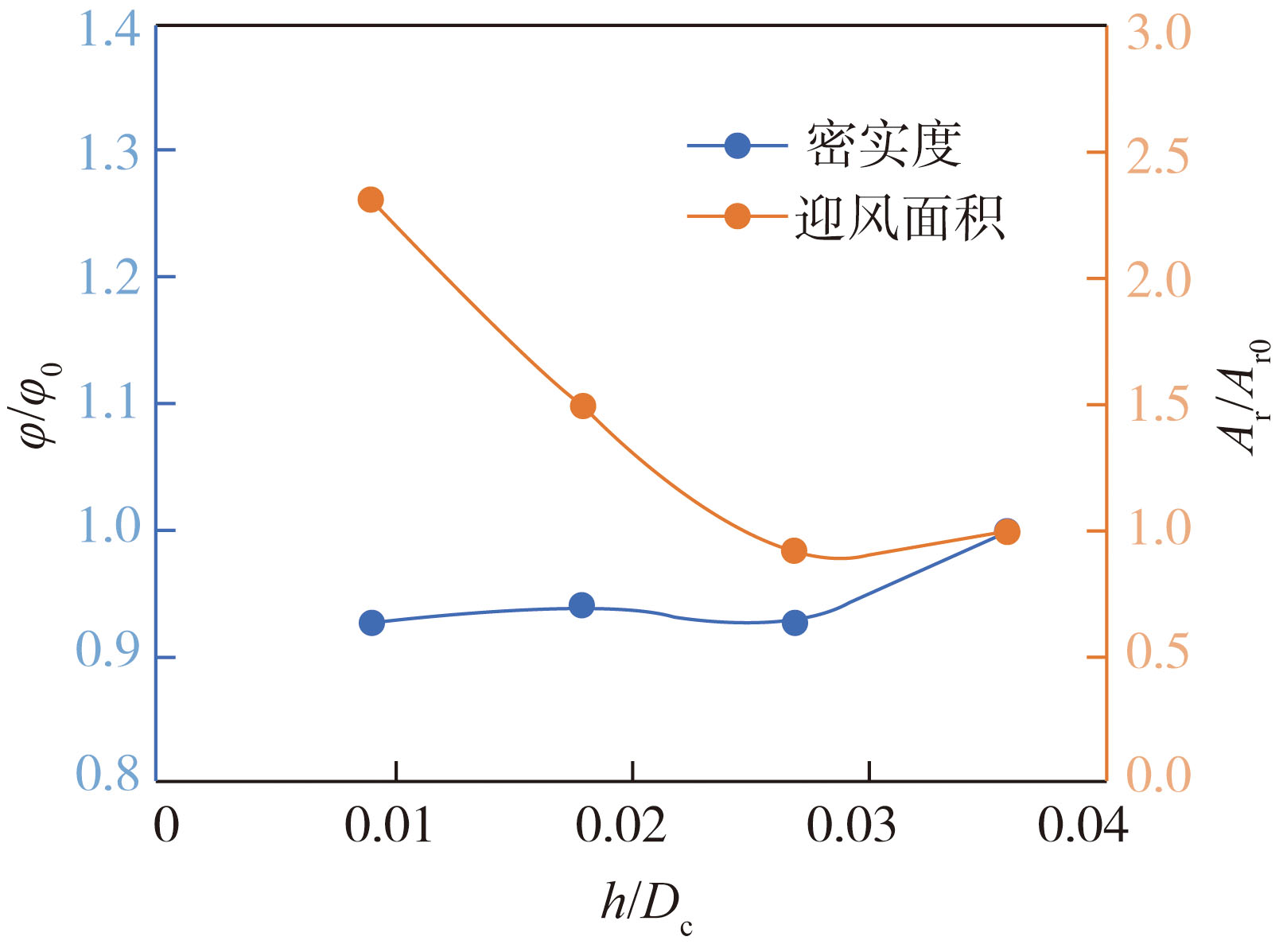

| h/Dc | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.0089 | 2110 | 3.30 | 0.77 | 586.21 | 0.96 |

| 0.0178 | 2112 | 3.15 | 0.78 | 380.13 | 0.94 |

| 0.0267 | 2122 | 3.12 | 0.77 | 232.89 | 0.91 |

| 0.0357 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

表5 不同径向厚度下EFP特征参数值(170μs时刻)

Table 5 Calculated results of characteristic parametervalues of EFPs with different radial thicknessesof pressing ring(170μs)

| h/Dc | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.0089 | 2110 | 3.30 | 0.77 | 586.21 | 0.96 |

| 0.0178 | 2112 | 3.15 | 0.78 | 380.13 | 0.94 |

| 0.0267 | 2122 | 3.12 | 0.77 | 232.89 | 0.91 |

| 0.0357 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

图15 不同压环径向厚度下φ/φ0-h/Dc、Ar/Ar0-h/Dc 曲线(170μs时刻)

Fig.15 φ/φ0-h/Dcand Ar/Ar0-h/Dc curves of EFPs with different radial thicknessses of pressing ring(170μs)

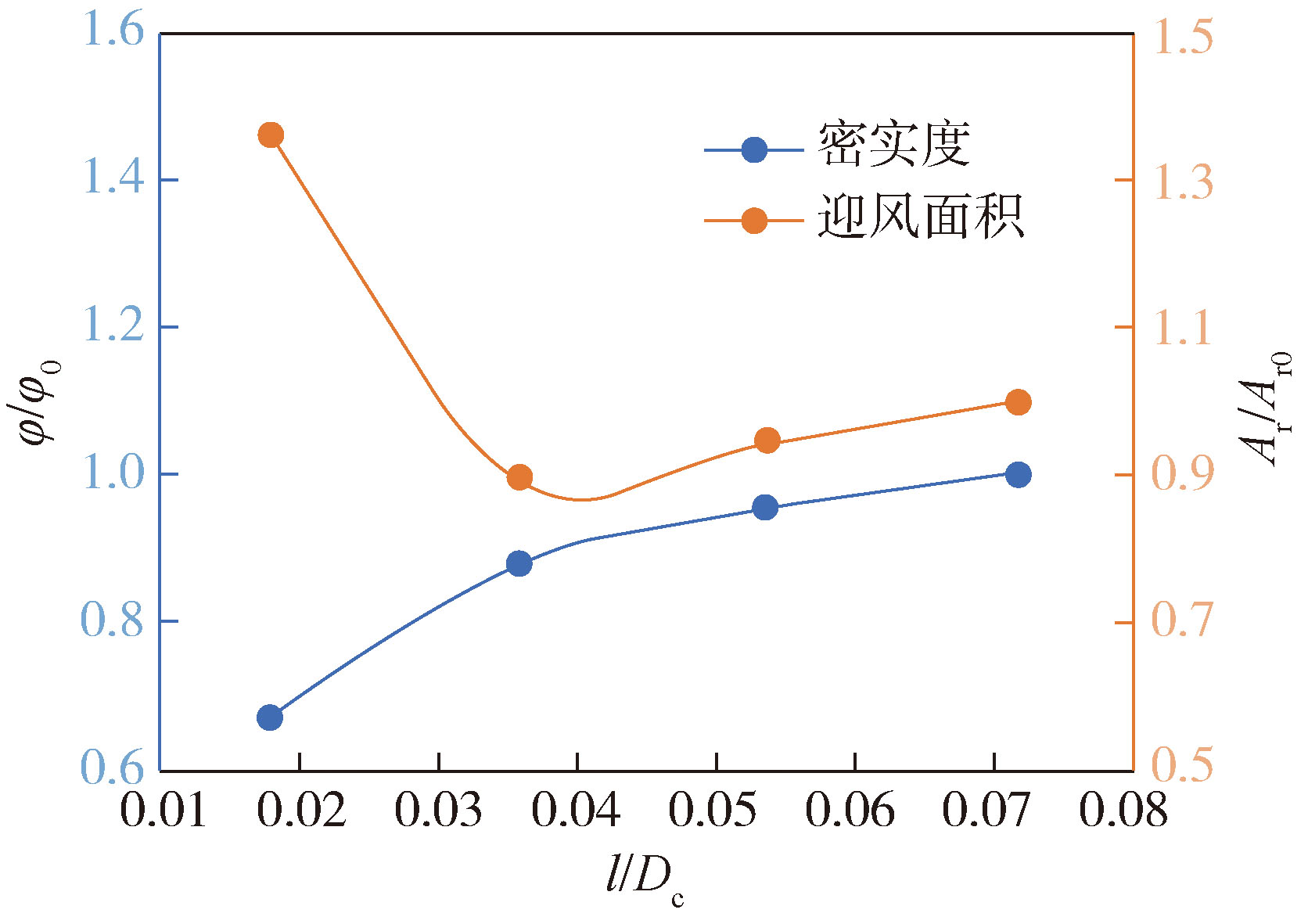

| l/Dc | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.0178 | 2084 | 3.65 | 0.56 | 346.36 | 0.98 |

| 0.0357 | 2098 | 3.38 | 0.73 | 226.98 | 0.91 |

| 0.0535 | 2120 | 3.07 | 0.79 | 240.53 | 0.88 |

| 0.0714 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

表6 不同轴向厚度下EFP特征参数值(170μs时刻)

Table 6 Calculated results of EFP characteristic parameter values of EFPs with different axial thicknesses of pressing ring(170μs)

| l/Dc | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.0178 | 2084 | 3.65 | 0.56 | 346.36 | 0.98 |

| 0.0357 | 2098 | 3.38 | 0.73 | 226.98 | 0.91 |

| 0.0535 | 2120 | 3.07 | 0.79 | 240.53 | 0.88 |

| 0.0714 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

图19 不同压环轴向厚度下φ/φ0-l/Dc、Ar/Ar0-l/Dc 曲线(170μs时刻)

Fig.19 φ/φ0-l/Dcand Ar/Ar0-l/Dc curves of EFPs writh different axial thicknesses of pressing ring(170μs)

| 截面形状系数ζ | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.5 | 2124 | 3.39 | 0.71 | 431.89 | 0.89 |

| 0.75 | 2120 | 3.17 | 0.74 | 268.22 | 0.89 |

| 1 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

表7 不同截面形状下EFP特征参数值(170μs时刻)

Table 7 Calculation results of EFP characteristic parameter valuesof EFPs with different sectional shapes of pressing ring(170μs)

| 截面形状系数ζ | v/(m·s-1) | λ | φ | Ar/mm2 | η |

|---|---|---|---|---|---|

| 0.5 | 2124 | 3.39 | 0.71 | 431.89 | 0.89 |

| 0.75 | 2120 | 3.17 | 0.74 | 268.22 | 0.89 |

| 1 | 2126 | 3.06 | 0.83 | 254.47 | 0.88 |

| [1] |

隋树元, 王树山. 终点效应学[M]. 北京: 国防工业出版社,2000:233-237.

|

|

|

|

| [2] |

朱志鹏, 门建兵, 蒋建伟, 等. 大长径比钽爆炸成型弹丸控制研究[J]. 兵工学报, 2018, 39(增刊1):29-36.

|

|

|

|

| [3] |

丁力, 蒋建伟, 王树有, 等. 钽爆炸成型弹丸成型及断裂特性[J]. 兵工学报, 2021, 42(增刊1):53-58.

|

|

|

|

| [4] |

杨绍卿. 灵巧弹药工程[M]. 北京: 国防工业出版社,2010:1-7.

|

|

|

|

| [5] |

李玉品, 周春桂, 王志军, 等. 夹层聚能装药EFP成型及侵彻数值模拟[J]. 兵器装备工程学报, 2019, 40(3):57-60.

|

|

|

|

| [6] |

付恒, 蒋建伟, 王树有, 等. 爆炸成型弹丸药型罩用高密度合金选取准则[J]. 兵工学报, 2022, 43(9):2330-2338.

|

|

doi: 10.12382/bgxb.2021.0826 |

|

| [7] |

卞梁. 高速碰撞中的SPH方法及其应用研究[D]. 合肥: 中国科学技术大学, 2011.

|

|

|

|

| [8] |

门建兵, 蒋建伟, 王树有. 爆炸冲击数值模拟技术基础[M]. 北京: 北京理工大学出版社, 2015.

|

|

|

|

| [9] |

黄正祥. 聚能装药理论与实践[M]. 北京: 北京理工大学出版社, 2014.

|

|

|

|

| [10] |

丁力, 蒋建伟, 门建兵, 等. 爆炸成型弹丸成型过程中的断裂数值模拟及机理分析[J]. 兵工学报, 2017, 38(3):417-423.

doi: 10.3969/j.issn.1000-1093.2017.03.001 |

|

doi: 10.3969/j.issn.1000-1093.2017.03.001 |

|

| [11] |

郑元枫, 王仕鹏, 李培亮, 等. 活性/金属串联爆炸成型弹丸侵爆耦合毁伤行为[J]. 兵工学报, 2023, 44(8):2273-2282.

doi: 10.12382/bgxb.2022.0356 |

|

|

|

| [12] |

|

| [13] |

|

| [14] |

胡德安, 韩旭, 肖毅华, 等. 光滑粒子法及其与有限元耦合算法的研究进展[J]. 力学学报, 2013, 45(5):639-652.

doi: 10.6052/0459-1879-13-092 |

|

|

|

| [15] |

吴嘉炜, 王新峰, 古兴瑾, 等. 基于FEM-SPH自适应耦合方法的蓝宝石DOP性能研究[J]. 南京航空航天大学学报, 2023, 55(4):711-717.

|

|

|

|

| [16] |

|

| [17] |

|

| [18] |

王昕, 蒋建伟, 王树有, 等. 爆炸成型弹丸侵彻钢靶的后效破片云实验研究[J]. 兵工学报, 2018, 39(7):1284-1290.

doi: 10.3969/j.issn.1000-1093.2018.07.005 |

|

doi: 10.3969/j.issn.1000-1093.2018.07.005 |

|

| [19] |

|

| [20] |

|

| [21] |

陈刚, 陈忠富, 徐伟芳, 等. 45钢的J-C损伤失效参量研究[J]. 爆炸与冲击, 2007, 27(2):131-135.

|

|

|

|

| [22] |

|

| [23] |

林加剑. EFP成型及其终点效应研究[D]. 合肥: 中国科学技术大学, 2009.

|

|

|

| [1] | 刘启明, 樊铮炎, 李涛, 杨伟龙, 韩旭. 高过载环境下弹载电子封装焊点失效机理[J]. 兵工学报, 2025, 46(9): 241006-. |

| [2] | 顾敏辉, 唐奎, 王金相, 夏靖雯, 李渊博, 王鸿飞. 带切缝PELE的侵彻破碎特性及毁伤后效[J]. 兵工学报, 2025, 46(8): 240898-. |

| [3] | 安骋远, 刘海鹏, 刘彦, 任炜. 椭圆截面柱形炸药爆炸冲击波威力特性[J]. 兵工学报, 2025, 46(8): 240969-. |

| [4] | 李青松, 王磊, 赵宁, 张笑天, 张磊, 王克鸿. 电弧增材框体结构有限元仿真模拟与实验[J]. 兵工学报, 2025, 46(7): 240629-. |

| [5] | 闫铭, 王昕捷, 黄风雷, 尤飒. 高超声速气动加热下战斗部装药热-点火响应与典型结构热防护特性[J]. 兵工学报, 2025, 46(6): 240401-. |

| [6] | 倪蓥锋, 陈小伟. 柱形弹超高速撞击加筋板架结构的破片群特征分析[J]. 兵工学报, 2025, 46(6): 240812-. |

| [7] | 杨茜, 冯榆坤, 陈作钢, 张岩. 浅水条件下喷水推进船航态及喷射流形态研究[J]. 兵工学报, 2024, 45(S2): 123-132. |

| [8] | 姜豪杰, 彭永, 孙宇雁, 王子国, 徐佳沛. RC桥墩的爆炸毁伤规律及快速计算模型[J]. 兵工学报, 2024, 45(S2): 305-316. |

| [9] | 许辉, 陈作钢, 蔡佑林. 基于壁模化大涡数值模拟的喷水推进泵内湍流运动特性分析[J]. 兵工学报, 2024, 45(S2): 55-64. |

| [10] | 金文, 蒋建伟, 门建兵, 李梅, 李海峰, 周鑫. 柱形容器约束下内装粉体冲击响应特性[J]. 兵工学报, 2024, 45(S1): 183-190. |

| [11] | 张琨, 赵长啸, 韩彪, 纪冲, 张波, 张凯凯, 唐蓉. 多弹丸协同冲击下柱壳装药响应特性数值模拟及试验[J]. 兵工学报, 2024, 45(S1): 70-80. |

| [12] | 王卿硕, 郭磊, 高洪寅, 何源, 王传婷, 陈鹏翔, 何勇. 梯度弹体结构轴向振动仿真研究[J]. 兵工学报, 2024, 45(S1): 191-199. |

| [13] | 杨贵涛, 郭锐, 宋浦, 高光发, 俞旸晖. 形成串联爆炸成型弹丸的组合药型罩结构参数研究[J]. 兵工学报, 2024, 45(9): 3056-3070. |

| [14] | 鲁航, 刘昊然, 陈泰然, 黄彪, 王国玉, 陈慧岩. 喷水推进两栖车辆水面航行特性试验与数值计算研究[J]. 兵工学报, 2024, 45(8): 2629-2645. |

| [15] | 郭俊廷, 余永刚. 埋头弹药二次点火过程复杂流场特性[J]. 兵工学报, 2024, 45(7): 2282-2293. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4