主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2023, Vol. 44 ›› Issue (7): 2080-2091.doi: 10.12382/bgxb.2022.0225

收稿日期:2022-04-02

上线日期:2023-07-30

通讯作者:

基金资助:

GUO Qing1, LUO Kai1, GENG Shaohang2, QIN Kan1,*( )

)

Received:2022-04-02

Online:2023-07-30

摘要:

为研究水下半闭式循环动力系统中高压换热器的性能,建立适用于高压下含大比例不凝气体的蒸汽凝结过程的数值模型,并考虑重力对水平套管式换热器的燃气流道进行多工况仿真计算与试验验证。研究结果表明:由于重力的存在,管道顶部和底部的液膜厚度不均匀,同时管内气相工质会产生二次旋流,两种作用将导致管内换热的不均匀特性;管径的减小将使管内工质流速增加,增大雷诺数的同时也使底部液膜变薄,有助于增强换热;流速增加削弱了重力的影响,使管道顶部和底部换热强度的差距变小;在所设工况下,即使考虑总换热面积的缩减,减小管径仍有助于总换热功率的提升;试验与仿真的管内温度最大误差为19.5%。所得成果可为水下半闭式循环动力系统高压换热器的设计提供参考。

郭庆, 罗凯, 耿少航, 秦侃. 含不凝气体的蒸汽凝结换热数值研究[J]. 兵工学报, 2023, 44(7): 2080-2091.

GUO Qing, LUO Kai, GENG Shaohang, QIN Kan. Numerical Study of Condensation Heat Transfer of Steam with Non-condensable Gas[J]. Acta Armamentarii, 2023, 44(7): 2080-2091.

| 组分 | 质量分数/% | 特性 |

|---|---|---|

| CO | 0.26 | 不溶于水 |

| CO2 | 20.47 | 不溶于水 |

| H2 | 0.12 | 不溶于水 |

| N2 | 5.48 | 不溶于水 |

| HCl | 8.44 | 可溶于水 |

| H2O | 65.18 | 可凝结 |

表1 HAP三组元推进剂燃烧产物组成

Table 1 Combustion products of the HAP tri-component propellant

| 组分 | 质量分数/% | 特性 |

|---|---|---|

| CO | 0.26 | 不溶于水 |

| CO2 | 20.47 | 不溶于水 |

| H2 | 0.12 | 不溶于水 |

| N2 | 5.48 | 不溶于水 |

| HCl | 8.44 | 可溶于水 |

| H2O | 65.18 | 可凝结 |

| 研究者 | 研究类型 | 工质种类 | 压力/MPa |

|---|---|---|---|

| Kuhn[ | 试验研究 | 空气、氦气 | 0.1~0.5 |

| Lee等[ | 试验研究 | 氮气 | 0.1~0.13 |

| Ren等[ | 试验研究 | 空气 | 0.1~0.4 |

| 马喜振[ | 试验研究 | 氮气、氩气 | 0.2~5.6 |

| Park等[ | 试验研究 | 空气 | 0.19~0.49 |

| Ji等[ | 试验研究 | 未注明 | 0.02~0.07 |

| Groff等[ | 数值研究 | 空气 | 0.1 |

| Bian等[ | 数值研究 | 空气 | 0.1~0.4 |

| 耿少航等[ | 数值研究 | CO2 | 10 |

表2 部分已有研究涉及的工况范围

Table 2 Working conditions of the research mentioned above

| 研究者 | 研究类型 | 工质种类 | 压力/MPa |

|---|---|---|---|

| Kuhn[ | 试验研究 | 空气、氦气 | 0.1~0.5 |

| Lee等[ | 试验研究 | 氮气 | 0.1~0.13 |

| Ren等[ | 试验研究 | 空气 | 0.1~0.4 |

| 马喜振[ | 试验研究 | 氮气、氩气 | 0.2~5.6 |

| Park等[ | 试验研究 | 空气 | 0.19~0.49 |

| Ji等[ | 试验研究 | 未注明 | 0.02~0.07 |

| Groff等[ | 数值研究 | 空气 | 0.1 |

| Bian等[ | 数值研究 | 空气 | 0.1~0.4 |

| 耿少航等[ | 数值研究 | CO2 | 10 |

| 参数 | 数值 |

|---|---|

| 入口质量流量/(g·s-1) | 10 |

| 入口温度/K | 575 |

| 入口水蒸气过热度/K | 2.5 |

| 出口压力/MPa | 10 |

| 壁面温度/K | 545 |

| 工质种类 | 水蒸气、CO2 |

| CO2质量分数 | 0.3 |

表3 仿真计算的边界条件

Table 3 Boundary conditions for simulations

| 参数 | 数值 |

|---|---|

| 入口质量流量/(g·s-1) | 10 |

| 入口温度/K | 575 |

| 入口水蒸气过热度/K | 2.5 |

| 出口压力/MPa | 10 |

| 壁面温度/K | 545 |

| 工质种类 | 水蒸气、CO2 |

| CO2质量分数 | 0.3 |

| 参数 | 数值 |

|---|---|

| 燃气通道入口压力/MPa | 10 |

| 燃气通道入口温度/K | 1100 |

| 燃气通道出口温度/K | 340 |

| 冷却水通道入口压力/MPa | 5 |

| 冷却水通道入口温度/K | 280 |

| 冷却水通道出口温度/K | 600 |

| 燃气通道入口水蒸气体积分数/% | 7 |

表4 试验工况参数

Table 4 Operation parameters of the experiment

| 参数 | 数值 |

|---|---|

| 燃气通道入口压力/MPa | 10 |

| 燃气通道入口温度/K | 1100 |

| 燃气通道出口温度/K | 340 |

| 冷却水通道入口压力/MPa | 5 |

| 冷却水通道入口温度/K | 280 |

| 冷却水通道出口温度/K | 600 |

| 燃气通道入口水蒸气体积分数/% | 7 |

| 工况 | 网格数 | 近壁面第1层 网格厚度/mm | 径向网格 增长率 | 平均y+ |

|---|---|---|---|---|

| 网格1 | 242万 | 0.012 | 1.2 | 1.09 |

| 网格2 | 389万 | 0.010 | 1.2 | 0.92 |

| 网格3 | 627万 | 0.008 | 1.2 | 0.86 |

表5 网格无关性研究中各工况计算网格设置参数

Table 5 Mesh setting parameters in grid independence study

| 工况 | 网格数 | 近壁面第1层 网格厚度/mm | 径向网格 增长率 | 平均y+ |

|---|---|---|---|---|

| 网格1 | 242万 | 0.012 | 1.2 | 1.09 |

| 网格2 | 389万 | 0.010 | 1.2 | 0.92 |

| 网格3 | 627万 | 0.008 | 1.2 | 0.86 |

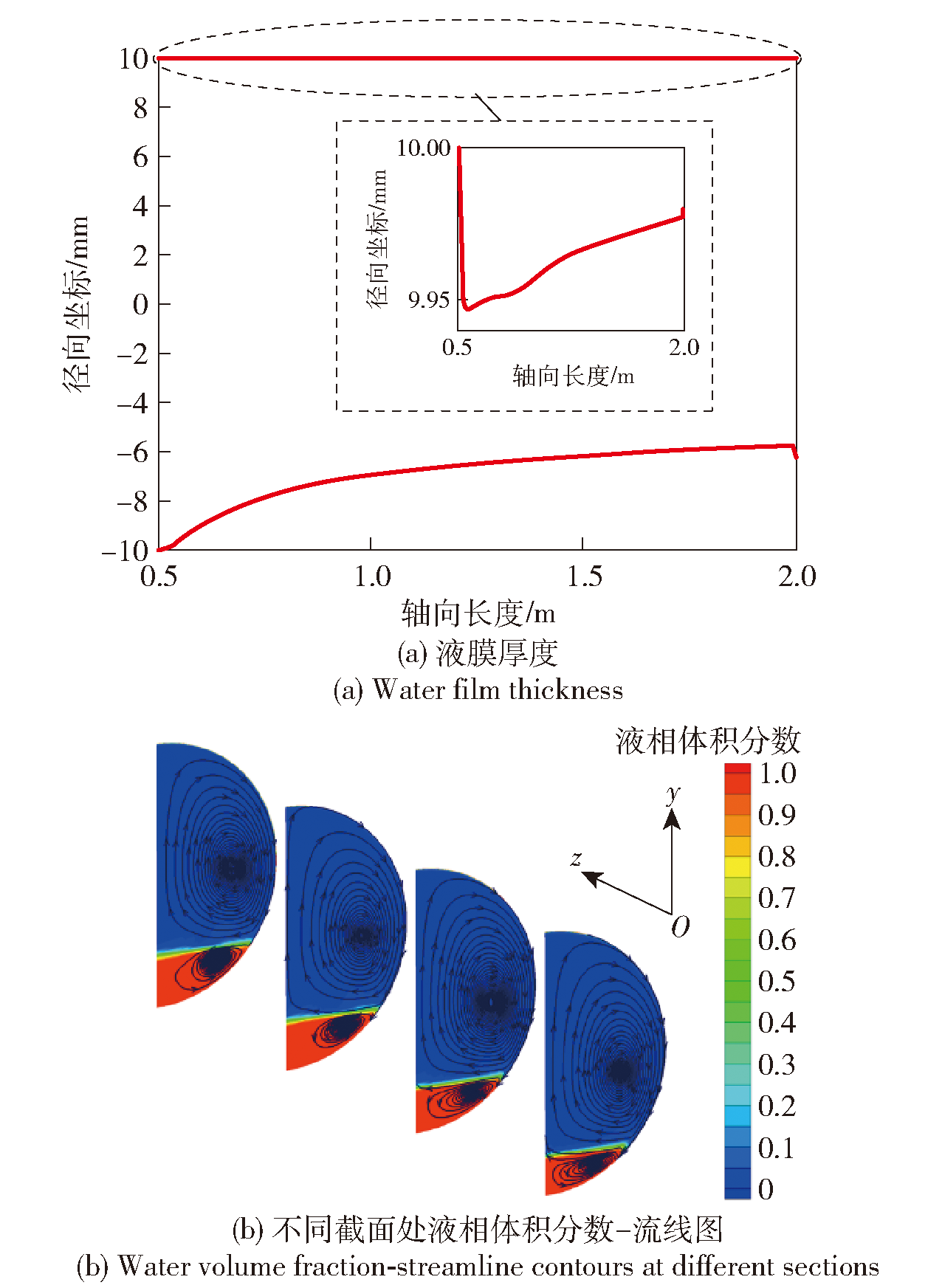

图10 换热器管道的液膜厚度和z=1.0m、1.2m、1.4m和1.6m处的液相体积分数-流线图

Fig.10 Water film thickness and water volume fraction-streamline contours at z=1.0m, 1.2m, 1.4m and 1.6m of the heat exchanger pipe

| [1] |

钟宏伟, 李国良, 宋林桦, 等. 国外大型无人水下航行器发展综述[J]. 水下无人系统学报, 2018, 26(4): 273-282.

|

|

|

|

| [2] |

任丽彬, 桑林, 赵青, 等. AUV动力电池应用现状及发展趋势[J]. 电源技术, 2017, 41(6): 952-955.

|

|

|

|

| [3] |

|

| [4] |

白杰, 党建军, 罗凯, 等. 水下航行器闭式循环动力系统动态仿真[J]. 鱼雷技术, 2016, 24(6): 438-443.

|

|

|

|

| [5] |

|

| [6] |

doi: 10.1016/S0029-5493(97)00185-4 URL |

| [7] |

|

| [8] |

doi: 10.1016/j.nucengdes.2007.07.001 URL |

| [9] |

doi: 10.1016/j.ijheatmasstransfer.2014.11.041 URL |

| [10] |

马喜振. 高压下非凝性气体对蒸汽冷凝传热特性影响研究[D]. 北京: 清华大学, 2017.

|

|

|

|

| [11] |

doi: 10.1016/S0301-9322(97)00022-0 URL |

| [12] |

doi: 10.1016/j.applthermaleng.2020.115264 URL |

| [13] |

doi: 10.1016/j.nucengdes.2015.11.034 URL |

| [14] |

|

| [15] |

doi: 10.1016/j.ijheatmasstransfer.2007.02.012 URL |

| [16] |

doi: 10.1016/j.icheatmasstransfer.2018.09.003 URL |

| [17] |

doi: 10.1016/j.nucengdes.2014.03.007 URL |

| [18] |

顾成勇. 含不凝气的竖直管内蒸汽冷凝数值模拟研究[D]. 大连: 大连理工大学, 2016.

|

|

|

|

| [19] |

耿少航, 党建军, 赵佳, 等. 高压下含大比例不凝气体的水蒸气对流冷凝数值仿真[J]. 水下无人系统学报, 2021, 29(1): 88-96.

|

|

|

|

| [20] |

doi: 10.1016/j.applthermaleng.2015.06.040 URL |

| [21] |

ANSYS. Ansys help[M]. Canonsburg,PA,US: Ansys Inc., 2016.

|

| [22] |

|

| [23] |

|

| [24] |

doi: 10.2514/3.12149 URL |

| [25] |

李宗吉, 王树宗, 陈华东, 等. 奥托-Ⅱ单组元推进剂燃烧产物平衡组成计算模型及仿真结果[J]. 舰船科学技术, 2004, 26(5): 27-30.

|

|

|

|

| [26] |

李晓莹. 传感器与测试技术[M]. 北京: 高等教育出版社, 2019.

|

|

|

| [1] | 贾启明, 姜毅, 杨莹, 赵子熹, 王志浩. 新型推力可控垂直发射装置及其内弹道规律[J]. 兵工学报, 2022, 43(7): 1596-1605. |

| [2] | 汪泰霖, 王野, 张富毅, 陈慧岩, 王国玉. 水陆两栖车矢量喷口装置设计与仿真[J]. 兵工学报, 2022, 43(4): 826-850. |

| [3] | 朱毅飞, 林德福, 莫雳, 叶建川. 四旋翼无人机旋翼对机身非定常气动干扰特性[J]. 兵工学报, 2022, 43(2): 410-422. |

| [4] | 刘双, 何广华, 王威, 高云. 附体对分层流中潜艇水动力特性的影响[J]. 兵工学报, 2021, 42(1): 108-117. |

| [5] | 徐路程, 郝雪颖, 肖凯涛, 宋伟伟, 陈春生. 爆炸型烟幕弹遮蔽效能仿真研究[J]. 兵工学报, 2020, 41(7): 1299-1306. |

| [6] | 权辉, 谢建, 李良, 张力. 火箭发射场坪排焰道口射流研究[J]. 兵工学报, 2020, 41(6): 1111-1122. |

| [7] | 钟阳, 王良明, 吴映锋. 基于计算流体力学与刚体动力学耦合的高速旋转弹丸弹道计算方法[J]. 兵工学报, 2020, 41(6): 1085-1095. |

| [8] | 王利利, 刘影, 李达钦, 吴钦, 王国玉. 固体火箭发动机水下超音速射流数值研究[J]. 兵工学报, 2019, 40(6): 1161-1170. |

| [9] | 郑秋亚, 苏宁亚, 梁益华. 欧拉方程数值求解的高精度通量分裂方法[J]. 兵工学报, 2019, 40(12): 2545-2550. |

| [10] | 赵欣怡, 周克栋, 赫雷, 陆野, 李峻松. 某大口径轻武器射流噪声的小波分析与数值模拟[J]. 兵工学报, 2019, 40(11): 2195-2203. |

| [11] | 张曼曼, 姜毅, 程李东, 杨桦, 刘琦. 基于嵌套网格的超声速子母弹分离数值分析[J]. 兵工学报, 2019, 40(1): 79-88. |

| [12] | 索文超, 许翔, 耿飞. 基于计算流体力学的车辆发动机散热器芯部外形优化[J]. 兵工学报, 2017, 38(9): 1839-1844. |

| [13] | 白治宁, 蔡卫军, 周景军, 王明洲. 助飞鱼雷雷箭分离多体气动干扰特性研究[J]. 兵工学报, 2017, 38(11): 2176-2183. |

| [14] | 周鹏, 曹从咏, 董浩. 高压气体发射装置内弹道特性及膛口流场分析[J]. 兵工学报, 2016, 37(9): 1612-1616. |

| [15] | 马晓冬, 郭锐, 刘荣忠, 吕胜涛. 涡环旋转伞充气过程及气动特性分析[J]. 兵工学报, 2015, 36(8): 1411-1416. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4