主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2023, Vol. 44 ›› Issue (10): 2995-3005.doi: 10.12382/bgxb.2022.0437

王蔚1,2, 沈杰1,2, 刘伟军1,2,*( ), 邢飞1,2, 张凯1,2, 李强1,2, 于兴福1,2

), 邢飞1,2, 张凯1,2, 李强1,2, 于兴福1,2

收稿日期:2022-05-24

上线日期:2023-10-30

通讯作者:

基金资助:

WANG Wei1,2, SHEN Jie1,2, LIU Weijun1,2,*( ), XING Fei1,2, ZHANG Kai1,2, LI Qiang1,2, YU Xingfu1,2

), XING Fei1,2, ZHANG Kai1,2, LI Qiang1,2, YU Xingfu1,2

Received:2022-05-24

Online:2023-10-30

摘要:

采用脉冲激光对7075铝合金表面原始氧化膜进行了激光清洗实验,探究振镜扫描速度对7075铝合金清洗表面形貌、氧含量和物相组成的影响规律,通过激光共聚焦显微镜和摩擦磨损试验机研究了7075铝合金的表面粗糙度和耐磨性能。研究结果表明:随着振镜扫描速度从2500mm/s 增加至4500mm/s,清洗表面氧含量和粗糙度均呈现先减小、后增大的趋势,当扫描速度为3500mm/s时,表面氧含量和粗糙度均达到最低,分别为1.45%和0.344μm,当扫描速度为2500mm/s时,清洗表面会出现严重的熔融现象,光斑凹坑以及波纹状凸起使得清洗表面粗糙度增大,当扫描速度小于等于3000mm/s时,清洗表面会发生热氧化,生成了主要由Al2O3组成的新的氧化膜;激光清洗后,粗糙度较小的熔融层可提高清洗表面减摩耐磨性;在10N的摩擦载荷下,严重熔融的清洗表面在摩擦过程中会发生疲劳剥落;清洗表面磨损机制主要以磨粒磨损和剥层磨损为主。

中图分类号:

王蔚, 沈杰, 刘伟军, 邢飞, 张凯, 李强, 于兴福. 激光清洗中振镜扫描速度对7075铝合金表面质量和摩擦特性的影响[J]. 兵工学报, 2023, 44(10): 2995-3005.

WANG Wei, SHEN Jie, LIU Weijun, XING Fei, ZHANG Kai, LI Qiang, YU Xingfu. Effect of Galvanometer Scanning Speed on Surface Quality and Friction Characteristics of 7075 Aluminum Alloy During Laser Cleaning[J]. Acta Armamentarii, 2023, 44(10): 2995-3005.

| 工艺参数 | 数值 |

|---|---|

| 波长/nm | 1064 |

| 扫描速度/(mm·s-1) | 2500, 3000, 3500, 4000, 4500 |

| 激光平均功率/W | 110 |

| 激光光斑直径/mm | 0.7 |

| 重复频率/kHz | 20 |

| 脉宽/ns | 60 |

表1 激光清洗主要工艺参数

Table 1 Main process parameters of laser cleaning

| 工艺参数 | 数值 |

|---|---|

| 波长/nm | 1064 |

| 扫描速度/(mm·s-1) | 2500, 3000, 3500, 4000, 4500 |

| 激光平均功率/W | 110 |

| 激光光斑直径/mm | 0.7 |

| 重复频率/kHz | 20 |

| 脉宽/ns | 60 |

| 材料 | 7075铝合金 | Al2O3 | MgO | MgAl2O4 |

|---|---|---|---|---|

| 熔点/℃ | 475~635 | 2054 | 2852 | 2130 |

表2 7075铝合金及其表面3种氧化物的熔点

Table 2 Melting points of 7075 aluminum alloy and three oxides on its surface

| 材料 | 7075铝合金 | Al2O3 | MgO | MgAl2O4 |

|---|---|---|---|---|

| 熔点/℃ | 475~635 | 2054 | 2852 | 2130 |

图11 不同扫描速度下7075铝合金表面原始氧化膜粗糙度变化示意图

Fig.11 Schematic diagram of roughness change of original oxide film on 7075 aluminum alloy surface at different scanning speeds

| 振镜扫描速度/ (mm·s-1) | 摩擦载荷/N | ||

|---|---|---|---|

| 1 | 5 | 10 | |

| 原始表面 | 0.6 | 3.4 | 8.3 |

| 2500 | 0.4 | 3.1 | 8.8 |

| 3000 | 0.2 | 2.5 | 7.5 |

| 3500 | 0.2 | 2.5 | 7.6 |

| 4000 | 0.3 | 2.7 | 7.7 |

| 4500 | 0.6 | 3.1 | 8.1 |

表3 不同振镜扫描速度清洗前后7075铝合金的磨损量

Table 3 Wear amounts of 7075 aluminum alloy before and after cleaning at different galvanometer scanning speeds mg

| 振镜扫描速度/ (mm·s-1) | 摩擦载荷/N | ||

|---|---|---|---|

| 1 | 5 | 10 | |

| 原始表面 | 0.6 | 3.4 | 8.3 |

| 2500 | 0.4 | 3.1 | 8.8 |

| 3000 | 0.2 | 2.5 | 7.5 |

| 3500 | 0.2 | 2.5 | 7.6 |

| 4000 | 0.3 | 2.7 | 7.7 |

| 4500 | 0.6 | 3.1 | 8.1 |

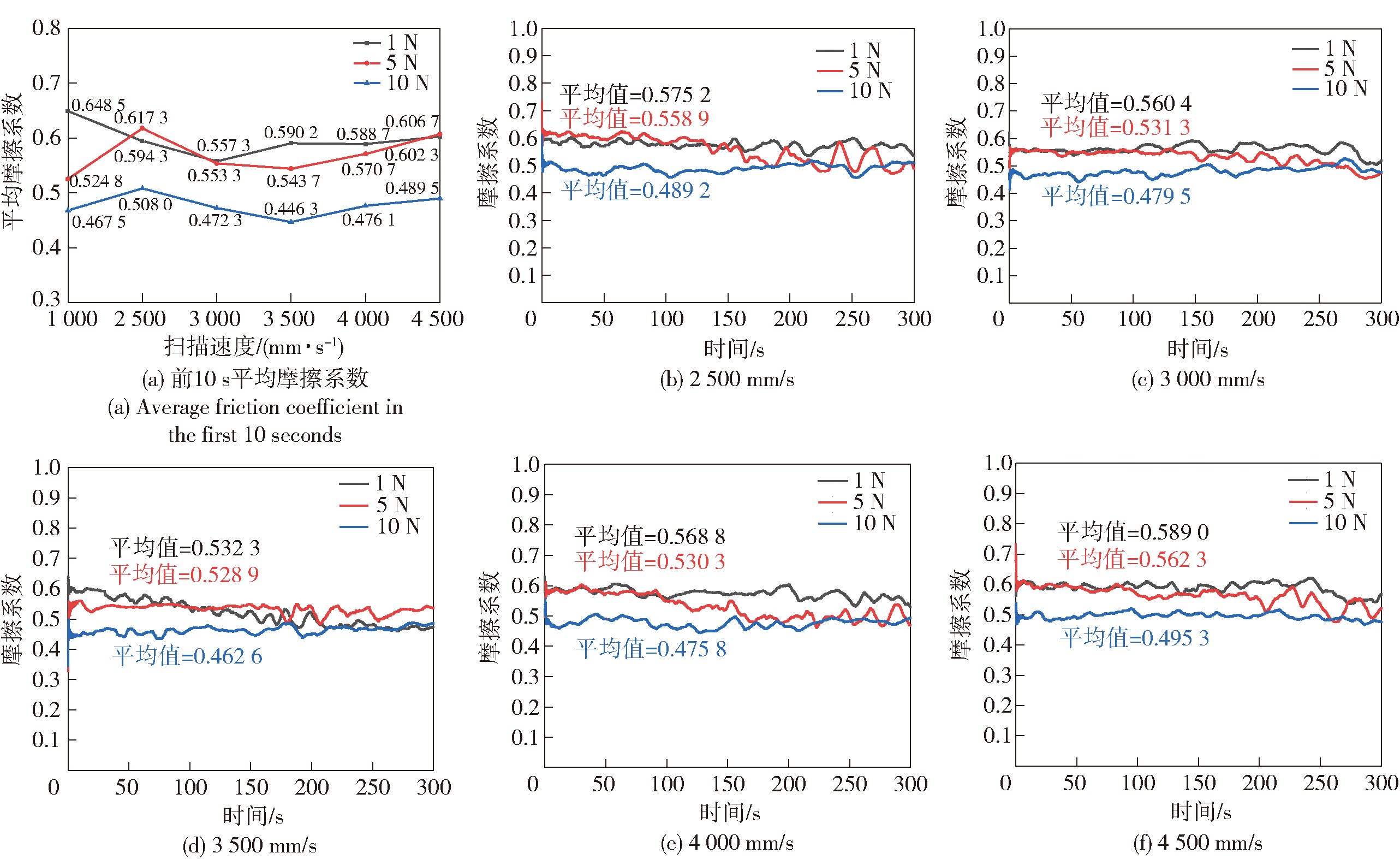

图17 干摩擦条件下不同扫描速度清洗后的表面摩擦系数变化

Fig.17 Variation curves of surface friction coefficient after cleaning at different scanning speeds under dry friction condition

| [1] |

doi: 10.1007/s11003-015-9851-7 URL |

| [2] |

丁清苗, 秦永祥, 高宇宁, 等. 焊接速度对飞机整体油箱异种铝合金搅拌摩擦焊接的影响[J]. 热加工工艺, 2021, 50(21): 133-139.

|

|

|

|

| [3] |

doi: 10.1016/j.jmrt.2017.10.012 URL |

| [4] |

郑建新, 刘威成, 段玉涛. 7075铝合金二维超声挤压加工表面质量影响因素及其交互作用研究[J]. 兵工学报, 2017, 38(6): 1231-1238.

doi: 10.3969/j.issn.1000-1093.2017.06.024 |

|

|

|

| [5] |

doi: 10.1007/s10973-017-6765-7 URL |

| [6] |

doi: 10.1080/00202967.2019.1675280 |

| [7] |

doi: 10.1016/j.jmapro.2019.04.015 URL |

| [8] |

常德华. 铝及铝合金电镀前的浸锌处理[J]. 中国金属通报, 2021(4): 82-83.

|

|

|

|

| [9] |

董世运, 宋超群, 闫世兴, 等. 激光清洗预处理对7A52铝合金激光焊缝成形质量的影响[J]. 装甲兵工程学院学报, 2017, 31(4): 100-105.

|

|

|

|

| [10] |

雷正龙, 田泽, 陈彦宾. 工业领域的激光清洗技术[J]. 激光与光电子学进展, 2018, 55(3): 60-72.

|

|

|

|

| [11] |

雷正龙, 孙浩然, 田泽, 等. 不同时间尺度的激光对铝合金表面油漆层清洗质量的影响[J]. 中国激光, 2021, 48(6): 65-74.

|

|

|

|

| [12] |

doi: 10.1007/s00339-004-3143-7 URL |

| [13] |

周建忠, 李华婷, 孙奇, 等. 基于清洗表面形貌的AH32钢激光除锈机制[J]. 光学精密工程, 2019, 27(8): 1754-1764.

|

|

doi: 10.3788/OPE. URL |

|

| [14] |

李宇强, 郭玲玉, 蒋平, 等. 铝合金激光清洗表面形貌变化的实验研究及工艺参数优化[J]. 中国激光, 2021, 48(22): 161-171.

|

|

|

|

| [15] |

doi: 10.1007/s00170-019-04395-6 |

| [16] |

沈浩, 蔡杰, 吕鹏, 等. 激光工艺参数对NiCoCrAlYSi熔覆层微观组织及性能的影响[J]. 兵工学报, 2021, 42(7): 1524-1534.

|

|

doi: 10.3969/j.issn.1000-1093.2021.07.020 |

|

| [17] |

聂金浩, 杨宜鑫, 李玉新, 等. 激光能量密度对激光熔覆NiCoCrAlY涂层组织与性能的影响[J]. 兵工学报, 2021, 42(5): 1083-1091.

doi: 10.3969/j.issn.1000-1093.2021.05.021 |

|

doi: 10.3969/j.issn.1000-1093.2021.05.021 |

|

| [18] |

万壮, 杨学锋, 夏国峰, 等. 激光频率对激光干式清洗机理及表面性能的影响[J]. 表面技术, 2021, 50(5): 70-77.

|

|

|

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

王朝晖, 吴志鑫, 杨康辉, 等. 仿生中性络合剂对花岗岩摩擦磨损行为的影响研究[J/OL]. 摩擦学学报, 2022.(2022-04-29)[2022-08-02]. https//doi.org/10.16078/j.tribology.2022079.

|

|

|

|

| [23] |

李鑫炎, 李灿阳, 王丹, 等. 激光扫描速度对Q345钢表面锈层清洗质量的影响[J]. 中国激光, 2020, 47(10): 1002010.

|

|

doi: 10.3788/CJL URL |

|

| [24] |

doi: 10.1016/j.matchemphys.2020.124022 URL |

| [1] | 刘扬, 秦国华, 吴竹溪, 娄维达, 赖晓春. 基于工件振动和刀具结构的周铣表面形貌分析与预测[J]. 兵工学报, 2023, 44(7): 2132-2146. |

| [2] | 杜凯, 焦黎, 颜培, 余建杭, 王玉彬, 仇天阳, 王西彬. 淬硬超高强度钢45CrNiMoVA硬车削加工性研究[J]. 兵工学报, 2023, 44(3): 773-782. |

| [3] | 董永亨, 李淑娟, 张倩, 李鹏阳, 李旗, 贾祯, 李言. 基于铣削系统动力学响应的球头铣刀铣削表面形貌建模[J]. 兵工学报, 2022, 43(8): 1977-1989. |

| [4] | 计时鸣, 邱文彬, 曾晰, 郗枫飞, 邱磊, 郑倩倩, 石梦. 软固结磨粒群微观力学特性分析与试验研究[J]. 兵工学报, 2019, 40(5): 1068-1076. |

| [5] | 安蓓, 李淑娟, 郝政, 赵雯, 王嘉宾, 梁列. 硬脆材料切割过程中基于线锯速度的切割力自适应控制[J]. 兵工学报, 2019, 40(2): 412-419. |

| [6] | 江禹安, 皮钧, 杨光, 姜涛, 沈志煌. 超声椭圆振动切削轨迹变化对表面形貌的影响[J]. 兵工学报, 2019, 40(10): 2170-2176. |

| [7] | 李俊烨,周曾炜,张心明,周立宾. 固体与液体两相磨粒流抛光异形曲面的质量控制因素研究[J]. 兵工学报, 2018, 39(4): 772-779. |

| [8] | 沈超, 周克栋, 陆野, 乔自平. 某大口径机枪内膛损伤对弹头挤进过程的影响研究[J]. 兵工学报, 2018, 39(12): 2320-2329. |

| [9] | 辛彬, 李淑娟, 李玉玺. 单晶硅电火花成形加工试验研究与工艺参数优化[J]. 兵工学报, 2017, 38(9): 1854-1861. |

| [10] | 赵二辉, 马彪, 李和言, 杜秋, 李慧珠, 马成男. 转速对湿式离合器局部润滑及摩擦特性影响研究[J]. 兵工学报, 2017, 38(4): 625-633. |

| [11] | 张国华, 李咚咚, 李茂伟, 张德远. 超声椭圆振动车削三维形貌形成研究[J]. 兵工学报, 2017, 38(10): 2002-2009. |

| [12] | 黄泽好, 刘通, 雷伟, 万鑫. 盘式制动器噪声、振动与声振粗糙度特性的复模态评价[J]. 兵工学报, 2016, 37(7): 1275-1281. |

| [13] | 巩亚东, 孙瑶, 刘寅. 低速单向走丝电火花线切割钛合金TC4表面粗糙度试验研究与建模[J]. 兵工学报, 2016, 37(6): 1058-1065. |

| [14] | 赵建,王兵,刘战强. 旋转超声滚压加工中的滚压力与滚压深度及表面形貌研究[J]. 兵工学报, 2016, 37(4): 696-704. |

| [15] | 刘忠乐, 石剑, 文无敌. 磁诱饵空中磁场验证的测量区域研究[J]. 兵工学报, 2015, 36(6): 1046-1051. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4