Responsible Institution: China Association for Science and Technology

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Acta Armamentarii ›› 2023, Vol. 44 ›› Issue (5): 1339-1349.doi: 10.12382/bgxb.2022.0086

Previous Articles Next Articles

TAO Lei1, LIU Jianhua1,2, XIA Huanxiong1,2,*( ), AO Xiaohui1,2, GAO Feng1

), AO Xiaohui1,2, GAO Feng1

Received:2022-02-15

Online:2022-06-21

Contact:

XIA Huanxiong

TAO Lei, LIU Jianhua, XIA Huanxiong, AO Xiaohui, GAO Feng. Temperature Field Prediction of Melt-cast Explosives Based on a B-spline Neural Network[J]. Acta Armamentarii, 2023, 44(5): 1339-1349.

Add to citation manager EndNote|Ris|BibTeX

| 项目 | 炸药 | 模具 | 冒口 |

|---|---|---|---|

| 材料 | DNAN基炸药 | Steel | 铝合金 |

| 导热系数λ/ (W·m-1K-1) | 0.72(20℃) | 50 | 176 |

| 0.70(65℃) | |||

| 0.64(110℃) | |||

| 密度ρ/(kg·m-3) | 1858(20℃) | 7940 | 2700 |

| 1810(65℃) | |||

| 1700(110℃) | |||

| 比热容cp/(J·kg-1K-1) | 1130(20℃) | 450 | 900 |

| 1320(65℃) | |||

| 1450(110℃) | |||

| 固相线温度Tsol/℃ | 85 | ||

| 液相线温度Tliq/℃ | 90 | ||

| 浇注温度Tj/℃ | 100 | ||

| 与外界的换热系数h1/ (W·m-2K-1) | 20 | 300 | 200 |

| 与炸药的换热系数h2/ (W·m-2K-1) | 200 | 100 | |

| 环境温度/℃ | T0 | ||

Table 1 Material properties of the explosive, mold and riser

| 项目 | 炸药 | 模具 | 冒口 |

|---|---|---|---|

| 材料 | DNAN基炸药 | Steel | 铝合金 |

| 导热系数λ/ (W·m-1K-1) | 0.72(20℃) | 50 | 176 |

| 0.70(65℃) | |||

| 0.64(110℃) | |||

| 密度ρ/(kg·m-3) | 1858(20℃) | 7940 | 2700 |

| 1810(65℃) | |||

| 1700(110℃) | |||

| 比热容cp/(J·kg-1K-1) | 1130(20℃) | 450 | 900 |

| 1320(65℃) | |||

| 1450(110℃) | |||

| 固相线温度Tsol/℃ | 85 | ||

| 液相线温度Tliq/℃ | 90 | ||

| 浇注温度Tj/℃ | 100 | ||

| 与外界的换热系数h1/ (W·m-2K-1) | 20 | 300 | 200 |

| 与炸药的换热系数h2/ (W·m-2K-1) | 200 | 100 | |

| 环境温度/℃ | T0 | ||

| 试验 组 | 水浴初始 温度 T10/℃ | 水浴降温 速率v1/ (℃·min-1) | 油浴初始 温度 T20/℃ | 油浴保温 时间 t2/h | 油浴降温 速率v2/ (℃·min-1) |

|---|---|---|---|---|---|

| 1 | 90 | 0.15 | 95 | 4 | 0.5 |

| 2 | 90 | 0.2 | 100 | 5 | 0.6 |

| 3 | 90 | 0.25 | 105 | 6 | 0.7 |

| 4 | 95 | 0.15 | 95 | 5 | 0.6 |

| 5 | 95 | 0.2 | 100 | 6 | 0.7 |

| 6 | 95 | 0.25 | 105 | 4 | 0.5 |

| 7 | 100 | 0.15 | 100 | 4 | 0.7 |

| 8 | 100 | 0.2 | 105 | 5 | 0.5 |

| 9 | 100 | 0.25 | 95 | 6 | 0.6 |

| 10 | 90 | 0.15 | 105 | 6 | 0.6 |

| 11 | 90 | 0.2 | 95 | 4 | 0.7 |

| 12 | 90 | 0.25 | 100 | 5 | 0.5 |

| 13 | 95 | 0.15 | 100 | 6 | 0.5 |

| 14 | 95 | 0.2 | 105 | 4 | 0.6 |

| 15 | 95 | 0.25 | 95 | 5 | 0.7 |

| 16 | 100 | 0.15 | 105 | 5 | 0.7 |

| 17 | 100 | 0.2 | 95 | 6 | 0.5 |

| 18 | 100 | 0.25 | 100 | 4 | 0.6 |

| 19 | 92 | 0.175 | 102.5 | 5.5 | 0.55 |

| 20 | 95 | 0.225 | 100 | 5 | 0.6 |

| 21 | 98 | 0.2 | 97.5 | 4.5 | 0.65 |

Table 2 Process parameters of the numerical tests

| 试验 组 | 水浴初始 温度 T10/℃ | 水浴降温 速率v1/ (℃·min-1) | 油浴初始 温度 T20/℃ | 油浴保温 时间 t2/h | 油浴降温 速率v2/ (℃·min-1) |

|---|---|---|---|---|---|

| 1 | 90 | 0.15 | 95 | 4 | 0.5 |

| 2 | 90 | 0.2 | 100 | 5 | 0.6 |

| 3 | 90 | 0.25 | 105 | 6 | 0.7 |

| 4 | 95 | 0.15 | 95 | 5 | 0.6 |

| 5 | 95 | 0.2 | 100 | 6 | 0.7 |

| 6 | 95 | 0.25 | 105 | 4 | 0.5 |

| 7 | 100 | 0.15 | 100 | 4 | 0.7 |

| 8 | 100 | 0.2 | 105 | 5 | 0.5 |

| 9 | 100 | 0.25 | 95 | 6 | 0.6 |

| 10 | 90 | 0.15 | 105 | 6 | 0.6 |

| 11 | 90 | 0.2 | 95 | 4 | 0.7 |

| 12 | 90 | 0.25 | 100 | 5 | 0.5 |

| 13 | 95 | 0.15 | 100 | 6 | 0.5 |

| 14 | 95 | 0.2 | 105 | 4 | 0.6 |

| 15 | 95 | 0.25 | 95 | 5 | 0.7 |

| 16 | 100 | 0.15 | 105 | 5 | 0.7 |

| 17 | 100 | 0.2 | 95 | 6 | 0.5 |

| 18 | 100 | 0.25 | 100 | 4 | 0.6 |

| 19 | 92 | 0.175 | 102.5 | 5.5 | 0.55 |

| 20 | 95 | 0.225 | 100 | 5 | 0.6 |

| 21 | 98 | 0.2 | 97.5 | 4.5 | 0.65 |

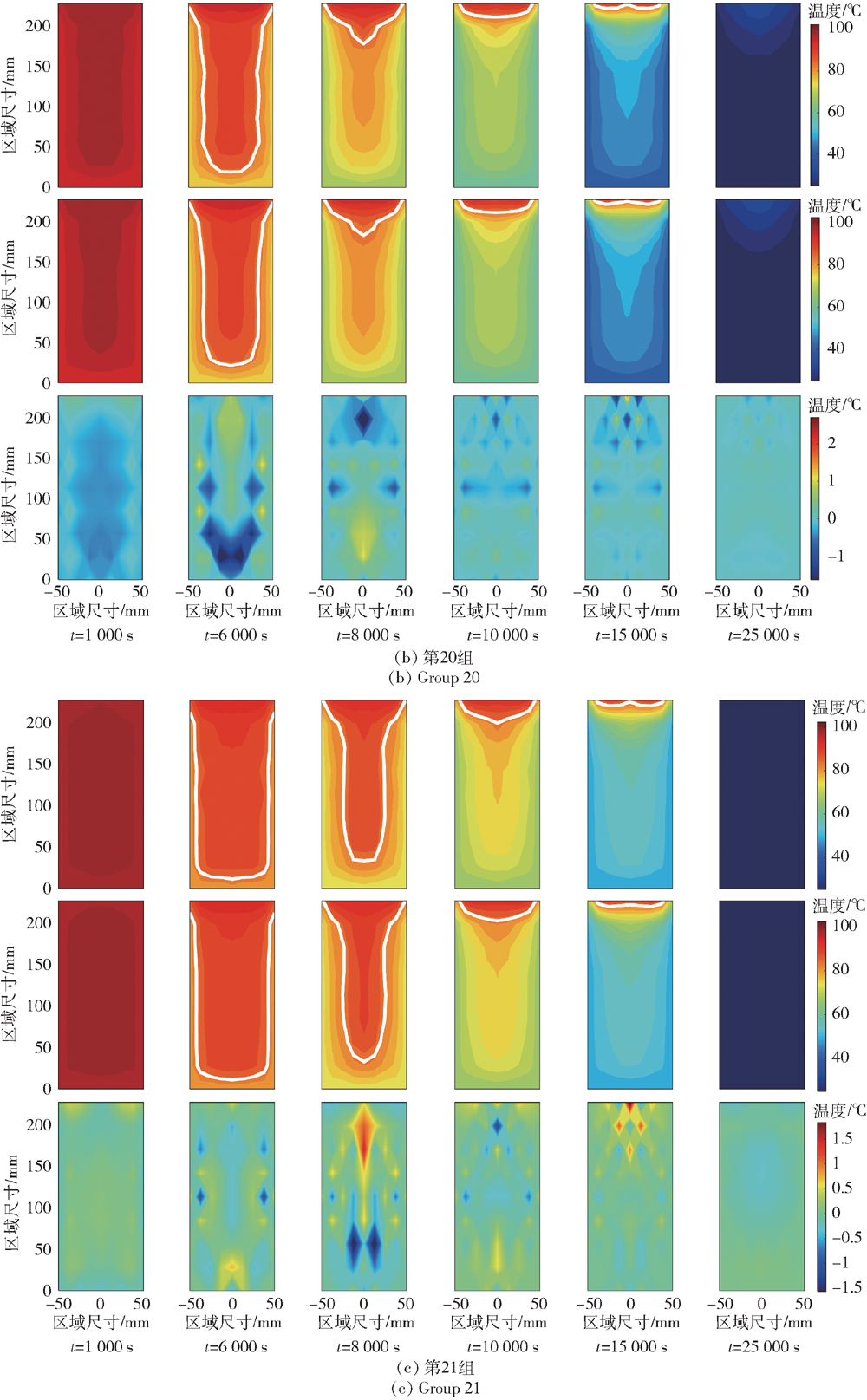

Fig.9 Comparison of the temperature field and solidification front between the simulation and prediction model I (The first line: the result of the simulation experiment;the second line:the result of the B-spline neural network prediction; the third line: prediction error distribution at each timepoint)

| 测试组 | 参数 | 时间/s | |||||

|---|---|---|---|---|---|---|---|

| 1000 | 6000 | 8000 | 10000 | 15000 | 25000 | ||

| μ | 0.0778 | -0.0921 | 0.0279 | 0.0578 | 0.0410 | 0.0704 | |

| 19 | σ | 0.2202 | 0.4657 | 0.5285 | 0.3485 | 0.3903 | 0.3197 |

| μabs | 0.1852 | 0.3434 | 0.3842 | 0.2260 | 0.2459 | 0.2070 | |

| ΔTmax | 0.5171 | 1.4519 | 1.6954 | 1.3802 | 1.3620 | 1.2470 | |

| μ | 0.1737 | -0.0025 | -0.0703 | -0.0063 | 0.0219 | -0.0286 | |

| 20 | σ | 0.2219 | 0.6407 | 0.4891 | 0.3089 | 0.4052 | 0.1813 |

| μabs | 0.2505 | 0.4450 | 0.3360 | 0.2283 | 0.2699 | 0.1153 | |

| ΔTmax | 0.5154 | 2.1489 | 2.6952 | 0.9250 | 1.5040 | 0.6326 | |

| μ | -0.0060 | 0.0074 | 0.1287 | -0.0456 | 0.0008 | 0.0145 | |

| 21 | σ | 0.1800 | 0.3327 | 0.5125 | 0.3314 | 0.3535 | 0.1936 |

| μabs | 0.1297 | 0.2368 | 0.3699 | 0.2586 | 0.2397 | 0.1574 | |

| ΔTmax | 0.5051 | 1.1007 | 1.8330 | 1.2420 | 1.2572 | 0.5140 | |

Table 3 Statistical parameters of the prediction error of model I

| 测试组 | 参数 | 时间/s | |||||

|---|---|---|---|---|---|---|---|

| 1000 | 6000 | 8000 | 10000 | 15000 | 25000 | ||

| μ | 0.0778 | -0.0921 | 0.0279 | 0.0578 | 0.0410 | 0.0704 | |

| 19 | σ | 0.2202 | 0.4657 | 0.5285 | 0.3485 | 0.3903 | 0.3197 |

| μabs | 0.1852 | 0.3434 | 0.3842 | 0.2260 | 0.2459 | 0.2070 | |

| ΔTmax | 0.5171 | 1.4519 | 1.6954 | 1.3802 | 1.3620 | 1.2470 | |

| μ | 0.1737 | -0.0025 | -0.0703 | -0.0063 | 0.0219 | -0.0286 | |

| 20 | σ | 0.2219 | 0.6407 | 0.4891 | 0.3089 | 0.4052 | 0.1813 |

| μabs | 0.2505 | 0.4450 | 0.3360 | 0.2283 | 0.2699 | 0.1153 | |

| ΔTmax | 0.5154 | 2.1489 | 2.6952 | 0.9250 | 1.5040 | 0.6326 | |

| μ | -0.0060 | 0.0074 | 0.1287 | -0.0456 | 0.0008 | 0.0145 | |

| 21 | σ | 0.1800 | 0.3327 | 0.5125 | 0.3314 | 0.3535 | 0.1936 |

| μabs | 0.1297 | 0.2368 | 0.3699 | 0.2586 | 0.2397 | 0.1574 | |

| ΔTmax | 0.5051 | 1.1007 | 1.8330 | 1.2420 | 1.2572 | 0.5140 | |

| 模型 | 参数 | 时间/s | |||||

|---|---|---|---|---|---|---|---|

| 1000 | 6000 | 8000 | 10000 | 15000 | 25000 | ||

| μ | -0.0668 | 0.1138 | -0.0747 | 0.1532 | 0.0005 | -0.0848 | |

| Ⅱ | σ | 0.1112 | 0.3019 | 0.4439 | 0.2759 | 0.4379 | 0.0628 |

| μabs | 0.1098 | 0.3297 | 0.3361 | 0.2622 | 0.2487 | 0.1055 | |

| ΔTmax | 0.3417 | 0.9500 | 1.1668 | 0.9906 | 1.2190 | 0.1917 | |

| μ | -0.1718 | 0.0822 | -0.1294 | -0.0128 | -0.1905 | 0.0347 | |

| Ⅲ | σ | 0.1222 | 0.2595 | 0.5383 | 0.2204 | 0.2852 | 0.0576 |

| μabs | 0.1839 | 0.1901 | 0.3508 | 0.1395 | 0.2267 | 0.0584 | |

| ΔTmax | 0.3758 | 1.1207 | 1.5442 | 0.9042 | 1.1408 | 0.1251 | |

Table 4 Statistical parameters of the prediction errors of model Ⅱ and model Ⅲ

| 模型 | 参数 | 时间/s | |||||

|---|---|---|---|---|---|---|---|

| 1000 | 6000 | 8000 | 10000 | 15000 | 25000 | ||

| μ | -0.0668 | 0.1138 | -0.0747 | 0.1532 | 0.0005 | -0.0848 | |

| Ⅱ | σ | 0.1112 | 0.3019 | 0.4439 | 0.2759 | 0.4379 | 0.0628 |

| μabs | 0.1098 | 0.3297 | 0.3361 | 0.2622 | 0.2487 | 0.1055 | |

| ΔTmax | 0.3417 | 0.9500 | 1.1668 | 0.9906 | 1.2190 | 0.1917 | |

| μ | -0.1718 | 0.0822 | -0.1294 | -0.0128 | -0.1905 | 0.0347 | |

| Ⅲ | σ | 0.1222 | 0.2595 | 0.5383 | 0.2204 | 0.2852 | 0.0576 |

| μabs | 0.1839 | 0.1901 | 0.3508 | 0.1395 | 0.2267 | 0.0584 | |

| ΔTmax | 0.3758 | 1.1207 | 1.5442 | 0.9042 | 1.1408 | 0.1251 | |

| [1] |

田勇. 炸药熔铸成型过程监测评价及数值模拟研究[D]. 北京: 中国科学院研究生院, 2009.

|

|

|

|

| [2] |

谢志毅, 王冬磊, 刘建波, 等. 炸药熔铸过程数值模拟研究[J]. 太赫兹科学与电子信息学报, 2014, 12(4):617-621.

|

|

|

|

| [3] |

焦云多, 曾晓华, 陈洋, 等. 大当量DNAN基熔铸炸药装药质量控制方法[J]. 兵工自动化, 2019, 38(8):23-26.

|

|

|

|

| [4] |

蒙君煚, 周霖, 金大勇, 等. 成型工艺对2,4-二硝基苯甲醚基熔铸炸药装药质量的影响[J]. 兵工学报, 2018, 39(9): 1719-1726.

doi: 10.3969/j.issn.1000-1093.2018.09.007 |

|

|

|

| [5] |

doi: 10.1002/(ISSN)1521-4087 URL |

| [6] |

doi: 10.1007/s11661-002-0041-5 URL |

| [7] |

郭朋林, 罗观, 习彦, 等. TNT基熔铸炸药冷却过程温度场变化规律研究[J]. 含能材料, 2010, 18(1):93-96.

|

|

|

|

| [8] |

马松, 袁俊明, 刘玉存, 等. DNAN炸药凝固过程的实验与数值模拟[J]. 含能材料, 2014, 22(2):240-244.

|

|

|

|

| [9] |

胡菲, 刘玉存, 袁俊明, 等. 炸药熔铸装药成型质量监测技术研究进展[J]. 兵器装备工程学报, 2021, 42(9):1-6.

|

|

|

|

| [10] |

马松, 袁俊明, 刘玉存, 等. 水浴和自然条件下熔铸炸药凝固过程的数值计算[J]. 火炸药学报, 2013, 36(3): 54-58.

|

|

|

|

| [11] |

刘威, 曹红松, 张虎成, 等. 分层浇铸工艺对熔铸药柱缩孔的影响研究[J]. 机电技术, 2015(6):122-125.

|

|

|

|

| [12] |

|

| [13] |

岳晓媛, 张会锁, 韩雪莲, 等. 大长径比熔铸装药热芯棒凝固工艺优化仿真[J]. 高压物理学报, 2021, 35(1):1-8.

|

|

|

|

| [14] |

张明明, 张斌宏, 万大奎, 等. 熔铸装药凝固过程温度场变化分析[J]. 弹药先进制造技术, 2021, 40(6): 93-96.

|

|

|

|

| [15] |

|

| [16] |

doi: 10.1016/j.addma.2020.101538 URL |

| [17] |

郝永志, 赵海东, 林嘉华. 基于机器学习的挤压铸造铝合金力学性能预测[J]. 特种铸造及有色合金, 2019, 39(8): 859-862.

doi: 10.15980/j.tzzz.2019.08.012 |

|

|

|

| [18] |

doi: 10.1016/j.jmapro.2020.01.016 URL |

| [19] |

doi: 10.1016/j.eng.2019.04.012 URL |

| [20] |

doi: 10.1109/TNN.2007.911749 pmid: 18334370 |

| [21] |

doi: 10.1016/j.ins.2010.09.031 URL |

| [22] |

doi: 10.1016/j.ymssp.2009.01.013 URL |

| [23] |

doi: 10.1007/s00521-011-0617-3 URL |

| [24] |

doi: 10.1007/s00521-020-04709-w |

| [25] |

|

| [26] |

徐应祥. 一种新型B-样条拟插值[J]. 仲恺农业工程学院学报, 2021, 34(4):60-65.

|

|

|

|

| [27] |

doi: 10.1002/acs.v28.3-5 URL |

| [28] |

doi: 10.1016/j.neucom.2011.11.016 URL |

| [29] |

|

| [30] |

|

| [31] |

谢心和, 赵东明, 吕明昊, 等. B样条神经网络用于区域重力异常曲面拟合[C]∥第十六届国家安全地球物理专题研讨会论文集. 北京:中国地球物理学会, 西安: 陕西省地球物理学会, 2020:39-44.

|

|

|

|

| [32] |

doi: 10.1007/s12652-020-02264-9 |

| [1] | CHEN Man, LIU Yujian, YU Liang, WANG Xu, ZHANG Cunzhen, HU Lin. Effects of Structural Characteristics of a Wet Multi-Disk Clutch on Contact Pressure [J]. Acta Armamentarii, 2023, 44(2): 406-416. |

| [2] | JIN Jiaxi, YANG Shujun, PENG Zengxiong, CHEN Qiao’er, LI Xueliang, PAN Hui, LIAN Zhuang. Temperature Field Analysis of Limited Slip Clutch Based on Equivalent Heat Transfer and Dynamic Heat Flux Partition [J]. Acta Armamentarii, 2023, 44(10): 3056-3066. |

| [3] | SHI You-an, WEI Dong, GUI Ye-wei, QIAN Wei-qi, ZENG Lei, LIU Xiao. Reconstruction of Transient Nonuniform Temperature Field in Solid Structures Using Inverse Methods [J]. Acta Armamentarii, 2016, 37(12): 2347-2355. |

| [4] | ZHANG Zhi-hao, SUN De-chuan. Calculation of Aerodynamic Heating and Ablation of Multi-layer Thermal Protection Material [J]. Acta Armamentarii, 2015, 36(10): 1949-1954. |

| [5] | BAO Yong-jie, GAO Hang, LIANG Yan-de, ZHU Guo-ping. Modeling and Experimental Research on Drilling Temperature Field of Carbon Fiber/ Epoxy Reinforced Composites [J]. Acta Armamentarii, 2013, 34(7): 846-852. |

| [6] | MENG Jun-jiong, ZHANG Xiang-rong, ZHOU Lin. Simulation of Solidification Process for DNAN-based Melt-cast Explosives [J]. Acta Armamentarii, 2013, 34(7): 810-814. |

| [7] | ZHANG Jun, LIU Rong-zhong, GUO Rui, QIU He, LIU Meng-meng. Surface Temperature Field of Projectile Flying at High Rotational Speed in Exterior Ballistic [J]. Acta Armamentarii, 2013, 34(4): 425-430. |

| [8] | GAO Ji, LIU Qing-yang, MA Xiao-fang, TANG Ming. Research on Thermal Physical Parameters and Surface Temperature Field of EDG Machining Honeycomb Ring [J]. Acta Armamentarii, 2013, 34(11): 1437-1441. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||