主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (5): 1625-1636.doi: 10.12382/bgxb.2022.1013

刘铁磊1, 王晓锋1, 徐豫新1,2,3,*( ), 李永鹏1, 张健1

), 李永鹏1, 张健1

收稿日期:2022-11-01

上线日期:2023-05-16

通讯作者:

LIU Tielei1, WANG Xiaofeng1, XU Yuxin1,2,3,*( ), LI Yongpeng1, ZHANG Jian1

), LI Yongpeng1, ZHANG Jian1

Received:2022-11-01

Online:2023-05-16

摘要:

为了研究钨球在高速撞击下的变形行为对侵彻效果的影响,对钨球侵彻半无限低碳钢靶进行试验研究,得到<1600m/s冲击速度下钨球变形特征和靶板侵彻深度随冲击速度的变化规律。在此基础上构建钨球侵彻塑性变形模型。将钨球变形模型和球形空腔膨胀阻力模型相结合,建立钨球变形侵彻深度计算模型。对比不同撞击速度下钨球变形侵彻模型、刚性侵彻模型的计算结果。对比结果表明,变形侵彻模型能够更加准确地计算钨球对半无限靶的侵彻深度,计算结果与试验相比最大误差20%(正误差15%,负误差5%),精度较刚性侵彻模型提升42.86%。

中图分类号:

刘铁磊, 王晓锋, 徐豫新, 李永鹏, 张健. 一种考虑球体变形的钨球侵彻低碳钢深度计算模型[J]. 兵工学报, 2024, 45(5): 1625-1636.

LIU Tielei, WANG Xiaofeng, XU Yuxin, LI Yongpeng, ZHANG Jian. A Calculation Modelfor Penetration Depth of Tungsten Ball against Low-carbon Steel Considering Sphere Deformation[J]. Acta Armamentarii, 2024, 45(5): 1625-1636.

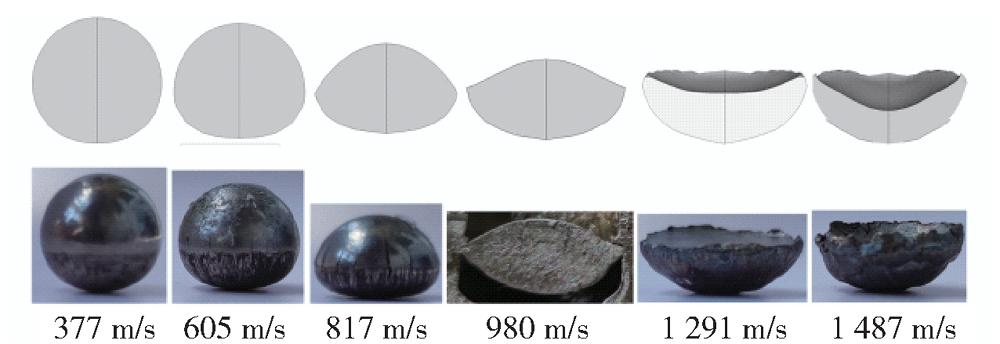

图2 回收试验弹靶变形特征(上为靶板侵彻弹坑,下为回收弹丸)

Fig.2 Deformation characteristics of recovered projectile and target (upper: penetrated craters on target plate, and below: recovered projectiles)

| 序号 | 剩余 质量/ g | 径向最 大半径/ mm | 轴向剩 余长度/ mm | 侵彻 深度/ mm | 靶板弹 孔直径/ mm | 冲击 速度/ (m·s-1) |

|---|---|---|---|---|---|---|

| (a) | 4.76 | 8.08 | 7.7 | 3.85 | 7.7 | 377.09 |

| (b) | 4.75 | 8.13 | 7.65 | 4.65 | 8.47 | 457.63 |

| (c) | 4.74 | 8.32 | 7.3 | 6.83 | 8.5 | 605.04 |

| (d) | 4.74 | 8.41 | 7.01 | 6.69 | 8.42 | 637.92 |

| (e) | 4.71 | 8.72 | 6.61 | 7.54 | 8.77 | 727.76 |

| (f) | 4.7 | 8.77 | 6.53 | 8.05 | 8.93 | 732.7 |

| (g) | 4.73 | 8.92 | 6.3 | 8.41 | 9.13 | 791.21 |

| (h) | 4.74 | 9.23 | 5.98 | 8.41 | 9.43 | 817.56 |

| (i) | - | - | - | 9.14 | 9.54 | 892.56 |

| (j) | - | - | - | 9.11 | 10.06 | 980.04 |

| (k) | - | - | - | 8.75 | 10.06 | 988.61 |

| (l) | - | - | - | 9.3 | 11.81 | 1074.63 |

| (m) | 4.62 | 11.44 | 4.2 | 11.13 | 12.32 | 1220.34 |

| (n) | 4.63 | 11.56 | 4.18 | 12.11 | 12.74 | 1244.24 |

| (o) | 4.62 | 11.7 | 3.96 | 11.6 | 13.15 | 1291.87 |

| (p) | 4.55 | 11.65 | 4.41 | 12.06 | 13.11 | 1343.28 |

| (q) | 4.59 | 11.71 | 4.83 | 13.27 | 14.23 | 1441.92 |

| (r) | 4.52 | 11.69 | 4.59 | 13.78 | 14.28 | 1489.66 |

表1 8mm直径93W钨球侵彻靶板后形状 特征参数

Table 1 Shape characteristic parameters of 8mm-diameter 93W sphere after penetrating target plate

| 序号 | 剩余 质量/ g | 径向最 大半径/ mm | 轴向剩 余长度/ mm | 侵彻 深度/ mm | 靶板弹 孔直径/ mm | 冲击 速度/ (m·s-1) |

|---|---|---|---|---|---|---|

| (a) | 4.76 | 8.08 | 7.7 | 3.85 | 7.7 | 377.09 |

| (b) | 4.75 | 8.13 | 7.65 | 4.65 | 8.47 | 457.63 |

| (c) | 4.74 | 8.32 | 7.3 | 6.83 | 8.5 | 605.04 |

| (d) | 4.74 | 8.41 | 7.01 | 6.69 | 8.42 | 637.92 |

| (e) | 4.71 | 8.72 | 6.61 | 7.54 | 8.77 | 727.76 |

| (f) | 4.7 | 8.77 | 6.53 | 8.05 | 8.93 | 732.7 |

| (g) | 4.73 | 8.92 | 6.3 | 8.41 | 9.13 | 791.21 |

| (h) | 4.74 | 9.23 | 5.98 | 8.41 | 9.43 | 817.56 |

| (i) | - | - | - | 9.14 | 9.54 | 892.56 |

| (j) | - | - | - | 9.11 | 10.06 | 980.04 |

| (k) | - | - | - | 8.75 | 10.06 | 988.61 |

| (l) | - | - | - | 9.3 | 11.81 | 1074.63 |

| (m) | 4.62 | 11.44 | 4.2 | 11.13 | 12.32 | 1220.34 |

| (n) | 4.63 | 11.56 | 4.18 | 12.11 | 12.74 | 1244.24 |

| (o) | 4.62 | 11.7 | 3.96 | 11.6 | 13.15 | 1291.87 |

| (p) | 4.55 | 11.65 | 4.41 | 12.06 | 13.11 | 1343.28 |

| (q) | 4.59 | 11.71 | 4.83 | 13.27 | 14.23 | 1441.92 |

| (r) | 4.52 | 11.69 | 4.59 | 13.78 | 14.28 | 1489.66 |

| 材料 | ρ/(g·cm-3) | E/GPa | G/GPa | υ | A/GPa |

|---|---|---|---|---|---|

| 93W | 17.6 | 350 | 160 | 0.284 | 1.506 |

| Q235 | 7.80 | 210 | 86.1 | 0.22 | 0.235 |

| 材料 | B/GPa | n | c | m | Tm/K |

| 93W | 1.506 | 0.12 | 0.016 | 1.00 | 1732 |

| Q235 | 0.750 | 0.25 | 0.015 | 1.3 | 1520 |

| 材料 | Tr/K | D1 | D2 | D3 | |

| 93W | 294 | 3 | 0 | 0 | |

| Q235 | 294 | 2.2 | 0 | 0 |

表2 弹靶材料本构参数

Table 2 Constitutive parameters of projectile and target materials

| 材料 | ρ/(g·cm-3) | E/GPa | G/GPa | υ | A/GPa |

|---|---|---|---|---|---|

| 93W | 17.6 | 350 | 160 | 0.284 | 1.506 |

| Q235 | 7.80 | 210 | 86.1 | 0.22 | 0.235 |

| 材料 | B/GPa | n | c | m | Tm/K |

| 93W | 1.506 | 0.12 | 0.016 | 1.00 | 1732 |

| Q235 | 0.750 | 0.25 | 0.015 | 1.3 | 1520 |

| 材料 | Tr/K | D1 | D2 | D3 | |

| 93W | 294 | 3 | 0 | 0 | |

| Q235 | 294 | 2.2 | 0 | 0 |

图4 钨球侵彻后形状特征的试验和仿真对比(上为仿真结果,下为试验回收弹丸)

Fig.4 Comparison of shape characteristics of experimental and simulated tungsten balls(upper: simulated result; below: recovered projectile)

| r0/m | ρp/(kg·m-3) | ρt/(kg·m-3) | Et/Pa | Yt/Pa |

|---|---|---|---|---|

| 0.004 | 17500 | 7830 | 2.1×1011 | 2.35×108 |

| n | ξ | μ | v0/(m·s-1) | Δt/s |

| 0.12 | 0.1 | 0.1 | 377~1487 | 1×10-8 |

表3 初始参数

Table 3 Initial parameters

| r0/m | ρp/(kg·m-3) | ρt/(kg·m-3) | Et/Pa | Yt/Pa |

|---|---|---|---|---|

| 0.004 | 17500 | 7830 | 2.1×1011 | 2.35×108 |

| n | ξ | μ | v0/(m·s-1) | Δt/s |

| 0.12 | 0.1 | 0.1 | 377~1487 | 1×10-8 |

图17 不同ξ取值下的加速度、速度、侵彻深度、球体变形半径时变规律

Fig.17 Time-varying rule of acceleration, velocity, penetration depth and sphere deformation radius under different ξ values

图18 不同h2取值下的加速度、速度、侵彻深度、球体变形半径时变规律

Fig.18 Time-varying rule of acceleration, velocity, penetration depth and sphere deformation radius under different h2 values

| [1] |

午新民. 钨合金球体对有限厚靶板侵彻的理论与试验研究[D]. 北京: 北京理工大学, 1999.

|

|

|

|

| [2] |

黄长强, 朱鹤松. 球形破片对靶板极限穿透速度公式的建立[J]. 弹箭与制导学报, 1993(2):58-61.

|

|

|

|

| [3] |

刘铁磊, 徐豫新, 王晓锋, 等. 钨合金球形破片侵彻低碳钢的弹道极限速度计算模型[J]. 兵工学报, 2022, 43(4):768-779.

|

|

doi: 10.12382/bgxb.2021.0448 |

|

| [4] |

张健, 徐豫新, 刘铁磊, 等. 钨球对高硬度钢斜侵彻效应[J]. 爆炸与冲击, 2022, 42(2):71-82.

|

|

|

|

| [5] |

朱学旺, 黄寅生, 李永池, 等. 贯穿有限厚金属靶板的一种模型[J]. 弹道学报, 2001(2):1-6.

|

|

|

|

| [6] |

朱文和, 赵有守, 李向东. 球形破片侵彻有限厚靶板的模型建立与计算[J]. 弹道学报, 1997(3):20-23.

|

|

|

|

| [7] |

徐豫新, 任杰, 王树山. 钨球正撞击下低碳钢板的极限贯穿厚度研究[J]. 北京理工大学学报, 2017, 37(6):551-556.

|

|

|

|

| [8] |

徐豫新, 王树山, 伯雪飞, 等. 钨合金球形破片对低碳钢的穿甲极限[J]. 振动与冲击, 2011, 30(5):192-195.

|

|

|

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

doi: 10.1016/j.dt.2019.01.006 |

| [14] |

|

| [15] |

|

| [16] |

|

| [17] |

|

| [18] |

doi: 10.1016/j.dt.2020.01.002 |

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [1] | 李萌, 武海军, 董恒, 任光, 张鹏, 黄风雷. 基于机器学习的混凝土侵彻深度预测模型[J]. 兵工学报, 2023, 44(12): 3771-3782. |

| [2] | 高飞, 邓树新, 张国凯, 纪玉国, 刘晨康, 王明洋. 缩比模型弹侵彻岩石靶尺寸效应试验研究与理论分析[J]. 兵工学报, 2023, 44(12): 3601-3612. |

| [3] | 刘铁磊, 徐豫新, 王晓锋, 张鹏, 张健. 钨合金球形破片侵彻低碳钢的弹道极限速度计算模型[J]. 兵工学报, 2022, 43(4): 768-779. |

| [4] | 刘德红, 徐庆林, 王向军. 腐蚀缺陷对921A钢力学-电化学性能的影响[J]. 兵工学报, 2022, 43(11): 2905-2915. |

| [5] | 贾鑫, 黄正祥, 徐梦雯, 肖强强. 聚能射流对厚壁移动靶的侵彻理论与数值模拟分析[J]. 兵工学报, 2019, 40(8): 1553-1561. |

| [6] | 张雪岩, 武海军, 李金柱, 皮爱国, 黄风雷. 弹体高速侵彻两种强度混凝土靶的对比研究[J]. 兵工学报, 2019, 40(2): 276-283. |

| [7] | 聂源, 蒋建伟, 王树有, 刘瀚. 爆炸反应装甲对爆炸成型弹丸侵彻效应影响的实验研究[J]. 兵工学报, 2018, 39(8): 1576-1581. |

| [8] | 高华, 熊超, 殷军辉. 弹丸侵彻多层异质复合靶板中装甲钢变形细观和微观机理研究[J]. 兵工学报, 2018, 39(8): 1565-1575. |

| [9] | 邓佳杰, 张先锋, 刘闯, 庞春旭, 王文杰. 头部非对称刻槽弹体侵彻混凝土目标性能研究[J]. 兵工学报, 2018, 39(7): 1249-1258. |

| [10] | 张欣欣, 闫雷, 武海军, 黄风雷. 考虑剪胀效应的混凝土动态球形空腔膨胀理论[J]. 兵工学报, 2016, 37(1): 42-49. |

| [11] | 刘志林, 孙巍巍, 王晓鸣, 冯君. 基于盖帽模型的混凝土动态球型空腔膨胀模型和侵彻阻力分析[J]. 兵工学报, 2015, 36(12): 2209-2216. |

| [12] | 孔祥振, 方秦, 吴昊. 考虑靶体自由表面和开裂区影响的可变形弹体斜侵彻脆性材料的终点弹道分析[J]. 兵工学报, 2014, 35(6): 814-821. |

| [13] | 梁增友, 高位, 陈智刚. 泡沫金属/金属管塑性变形缓冲器降低弹载设备过载的数值模拟[J]. 兵工学报, 2013, 34(8): 1041-1045. |

| [14] | 殷军辉, 郑坚, 倪新华, 贾长治, 崔凯波. 弹丸膛内运动过程中弹带塑性变形的宏观与微观机理研究[J]. 兵工学报, 2012, 33(6): 676-681. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4