Responsible Institution: China Association for Science and Technology

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Acta Armamentarii ›› 2025, Vol. 46 ›› Issue (6): 240371-.doi: 10.12382/bgxb.2024.0371

Previous Articles Next Articles

WANG Kai1, ZHENG Mengwei2, GONG Hao1,3,4,*( ), LIU Jianhua1,3,4, ZHAO Youlei2, LIU Shaoli1,3,4

), LIU Jianhua1,3,4, ZHAO Youlei2, LIU Shaoli1,3,4

Received:2024-05-15

Online:2025-06-28

Contact:

GONG Hao

CLC Number:

WANG Kai, ZHENG Mengwei, GONG Hao, LIU Jianhua, ZHAO Youlei, LIU Shaoli. Elastic-plastic Contact Calculation and Sealing Performance Analysis of Metal Sealing Ring[J]. Acta Armamentarii, 2025, 46(6): 240371-.

Add to citation manager EndNote|Ris|BibTeX

| 材料 | 屈服强度/ MPa | 弹性模量/ GPa | 切线模量/ MPa | 泊松比 |

|---|---|---|---|---|

| 30CrMnSiA | 835 | 206 | 2553 | 0.30 |

| TC11钛合金 | 900 | 107.8 | 1 814 | 0.34 |

| T2紫铜 | 70 | 108 | 868 | 0.35 |

Table 1 Material properties of different materials

| 材料 | 屈服强度/ MPa | 弹性模量/ GPa | 切线模量/ MPa | 泊松比 |

|---|---|---|---|---|

| 30CrMnSiA | 835 | 206 | 2553 | 0.30 |

| TC11钛合金 | 900 | 107.8 | 1 814 | 0.34 |

| T2紫铜 | 70 | 108 | 868 | 0.35 |

| 等效前后 | 弹性模量/ GPa | 泊松比 | 屈服强度/ MPa | 切线模量/ MPa | |

|---|---|---|---|---|---|

| 等效前 | 表面1 | 120 | 0.3 | 1200 | 10000 |

| 表面2 | 120 | 0.3 | 500 | 10000 | |

| 等效后 | 60 | 0.3 | 500 | 10000 | |

Table 2 Material properties before and after equivalence

| 等效前后 | 弹性模量/ GPa | 泊松比 | 屈服强度/ MPa | 切线模量/ MPa | |

|---|---|---|---|---|---|

| 等效前 | 表面1 | 120 | 0.3 | 1200 | 10000 |

| 表面2 | 120 | 0.3 | 500 | 10000 | |

| 等效后 | 60 | 0.3 | 500 | 10000 | |

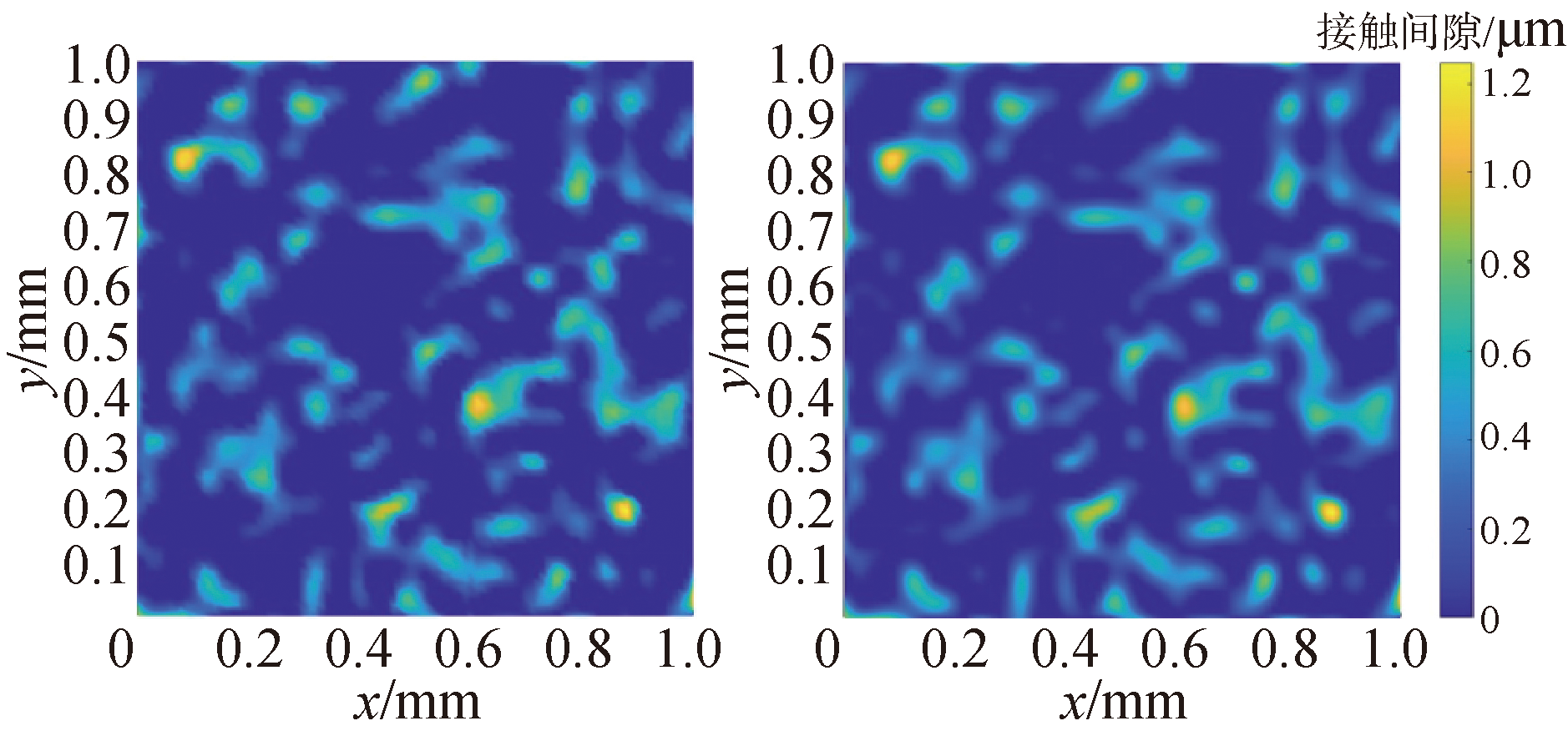

Fig.13 Calculated results of contact gap distribution obtained by finite element method(left)and finite element-boundary elementcoupling method(right)

| [1] |

段浩, 陈晖, 翟兆阳, 等. 基于支持向量机的氢混天然气发动机性能预测[J]. 兵工学报, 2022, 43(5):1002-1011.

|

|

|

|

| [2] |

陈庆, 陈利强, 康博. 往复运动橡胶O形密封圈密封机制及其特性的研究[J]. 润滑与密封, 2011, 36(6):76-78.

|

|

|

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

李远超. 金属橡胶密封件温度特性研究及专用试验台研制[D]. 哈尔滨: 哈尔滨工业大学, 2014.

|

|

|

|

| [7] |

|

| [8] |

|

| [9] |

张彤, 李德才, 李艳文. 磁性液体密封与迷宫密封组合密封的结构设计及优化[J]. 机械工程学报, 2022, 58(9):172-181.

|

|

|

|

| [10] |

|

| [11] |

黄伟旋, 岳婷, 林起崟, 等. 液体火箭发动机U形环密封界面优化设计[J]. 润滑与密封, 2024, 45(5):15-22.

|

|

|

|

| [12] |

|

| [13] |

傅磊, 雷学林, 章兰珠. 表面粗糙度对金属平垫泄漏率的影响[J]. 润滑与密封, 2023, 48(8):114-119.

|

|

|

|

| [14] |

李伟平, 贾占举, 路茜, 等. 金属封严环泄漏率预测方法[J]. 航空动力学报, 2019, 34(2):368-375.

|

|

|

|

| [15] |

|

| [16] |

刘检华, 张飞凯, 丁晓宇. 弹塑性粗糙表面实际接触面积演变规律研究[J]. 机械工程学报, 2021, 57(7):109-116.

|

|

|

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [1] | NI Yingfeng, CHEN Xiaowei. Characteristics of Fragment Cloud Produced by Hypervelocity Impact of Cylindrical Projectile on Stiffened Plate [J]. Acta Armamentarii, 2025, 46(6): 240812-240812. |

| [2] | WANG Yizhen, YIN Jianping, ZHANG Xuepeng, YI Jianya, LI Xudong. A Prediction Model for Dynamic Penetration of Shaped Charge Jet [J]. Acta Armamentarii, 2025, 46(6): 240932-240932. |

| [3] | CHEN Yusi, ZHANG Ning, FAN Jun, LI Bing, WANG Bin. A Fast Calculation Method for Acoustic Scattering of Cyclic Symmetric Structures [J]. Acta Armamentarii, 2025, 46(5): 240291-. |

| [4] | ZHOU Xun, WANG Hongwu, WANG Xusheng, WANG zheng, QU Junfeng, SUN Mengyong, PAN Jun. Finite Element Modeling of Si3N4 Ceramic Microstructure [J]. Acta Armamentarii, 2025, 46(4): 240407-. |

| [5] | ZHANG Cong, LU Junhua, YUE Mingkai. Design and Simulation of Bionic Composite Shock Absorption Structure for Imaging Fuze [J]. Acta Armamentarii, 2025, 46(2): 240021-. |

| [6] | JIN Yue, MIAO Fuxing. Impact Resistance and Energy Absorption Properties of CFRP Thin-walled Circular Tube with Porous Arrays [J]. Acta Armamentarii, 2025, 46(2): 240074-. |

| [7] | LI Xianghui, ZHANG Xingyu, HU Jiahao, LIU Yang, MA Bohan, WANG Yonggang, JIANG Zhaoxiu. Study on the Large Plasticity Model and Fracture Initiation Model Parameters of AISI 4340 Steel Targets [J]. Acta Armamentarii, 2025, 46(1): 231210-. |

| [8] | GAO Maoguo, LIU Rui, GUO Yansong, GENG Hengheng, CHEN Pengwan. Dynamic Deformation,Damage and Failure Behaviors of High-entropy HfZrTiTaAl Alloy [J]. Acta Armamentarii, 2025, 46(1): 231183-. |

| [9] | KONG Xiangqing, LI Ruonan, CHANG Yahui, FU Ying. Numerical Simulation of Blast Resistance of Foam-filled Auxetic Honeycomb Sandwich Structures [J]. Acta Armamentarii, 2024, 45(9): 3091-3104. |

| [10] | ZUO Mingshuo, XU Yuxin, LI Yongpeng, LI Xudong, GUO Delong, YANG Xiang. Dynamic Response of Directional Blast Relief Container Structure for Civil Aircraft under Internal Explosive Loading [J]. Acta Armamentarii, 2024, 45(7): 2383-2392. |

| [11] | JIA Jingjing, ZHANG Zhimin, YU Jianmin, XUE Yong, WU Ang. Numerical Simulation of Uniform Extrusion Forming and Die Structure Optimization of Lightweight Empennage-shaped Component Based on Response Surface Method [J]. Acta Armamentarii, 2024, 45(6): 1824-1839. |

| [12] | YANG Tuo, XIONG Shihui, WANG Jingcheng, ZHAO Xiangrun, WEN Yuquan. Actuation Noise Prediction and Decoupling of Pyrotechnic Separation Nut [J]. Acta Armamentarii, 2024, 45(3): 763-773. |

| [13] | XIANG Xinmei, LUO Linlin, FU Zushu, HE Shizhu. Effect of Gradient Mode on Mechanical Properties of Miura-ori Metamaterials [J]. Acta Armamentarii, 2024, 45(2): 618-627. |

| [14] | TAO Zihao, LI Xianglong, HU Qiwen, WANG Jianguo. Study and Analysis on Numerical Simulation of Empty Hole Effect Induced by Cutting Blasting [J]. Acta Armamentarii, 2024, 45(12): 4246-4258. |

| [15] | GAO Jian, ZOU Libo, YU Cungui. Numerical Simulation of Coating Spalling on Barrel Based on Phase-field Coupled Cohesive Force Model [J]. Acta Armamentarii, 2024, 45(11): 4081-4093. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||