主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (6): 1824-1839.doi: 10.12382/bgxb.2023.0187

贾晶晶1,2, 张治民1,3,*( ), 于建民3, 薛勇3, 吴昂3

), 于建民3, 薛勇3, 吴昂3

收稿日期:2023-03-09

上线日期:2023-06-01

通讯作者:

JIA Jingjing1,2, ZHANG Zhimin1,3,*( ), YU Jianmin3, XUE Yong3, WU Ang3

), YU Jianmin3, XUE Yong3, WU Ang3

Received:2023-03-09

Online:2023-06-01

摘要:

针对轻质镁合金尾翼正挤压成形金属流动不均匀和力学性能各向异性大的问题,提出一种可调控金属均匀流动的金属蓄料池模具结构。基于Deform-3D有限元模拟分析,采用Box-Behnken响应曲面法以金属蓄料池结构参数:深度h、池壁距尾翼芯部型腔长度D1、池壁距翼片型腔长度D2和池壁与翼片型腔之间夹角α为变量,建立出模口金属流速均方差和成形载荷与金属蓄料池结构参数之间的响应关系。响应曲面分析结果表明:最佳的金属蓄料池结构参数为h=7mm,D1=13mm,D2=6mm,α=11°。采用优化后的模具结构参数进行模拟验证和物理试验,金属流动不均匀和力学性能各向异性均得到改善,并成功试制出形状尺寸和力学性能指标满足要求的尾翼形零件。

中图分类号:

贾晶晶, 张治民, 于建民, 薛勇, 吴昂. 基于响应面法的轻质尾翼均匀挤压成形数值模拟及模具结构优化[J]. 兵工学报, 2024, 45(6): 1824-1839.

JIA Jingjing, ZHANG Zhimin, YU Jianmin, XUE Yong, WU Ang. Numerical Simulation of Uniform Extrusion Forming and Die Structure Optimization of Lightweight Empennage-shaped Component Based on Response Surface Method[J]. Acta Armamentarii, 2024, 45(6): 1824-1839.

| |

表1 平面凹模和不同深度金属蓄料池凹模不同步数对应的金属流动速度分布

Table 1 Metal flow velocity distributions for different steps of flat-surface female die structure and female die structure with metal reservoir

| |

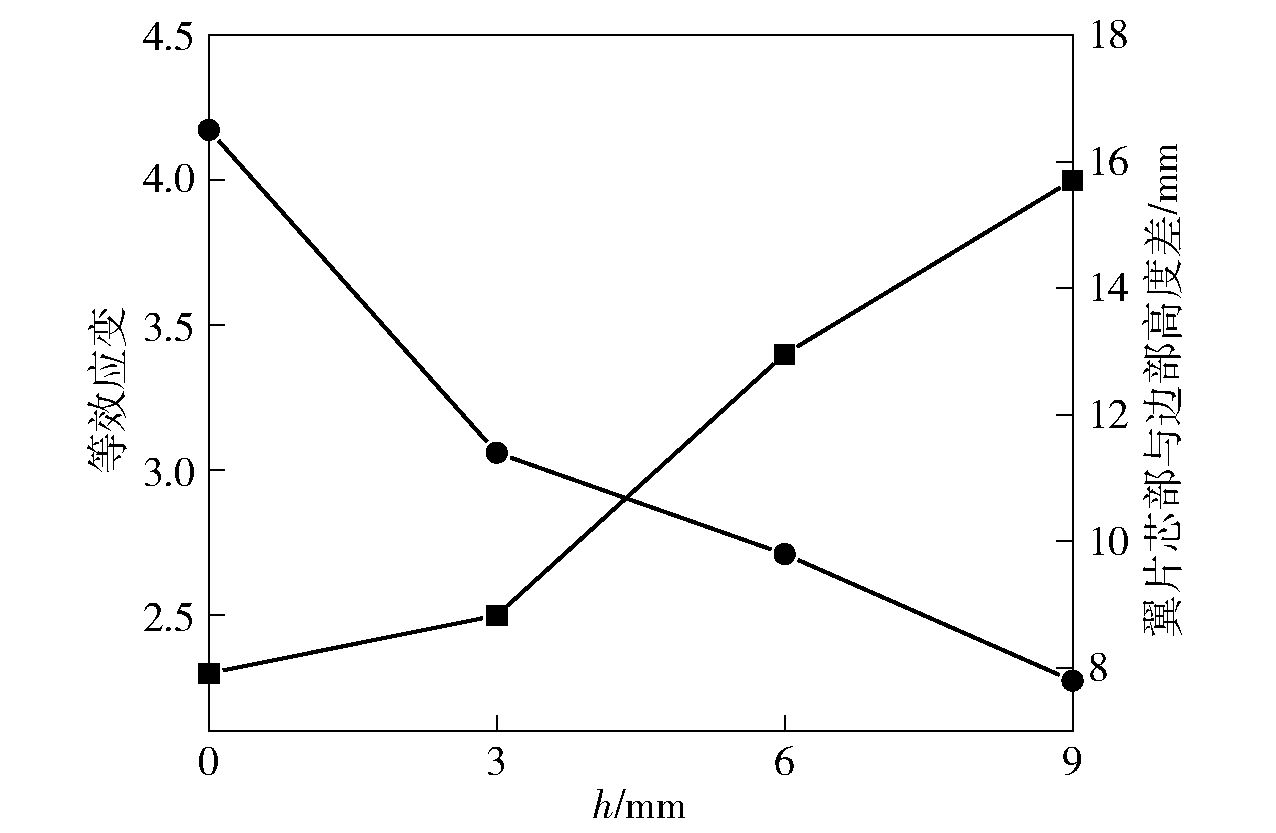

图11 不同深度金属蓄料池对应的等效应变和成形翼片端部高度差折线图

Fig.11 The equivalent strain and the line chart of height difference at the end of empennage vane of metal reservoir with different depths

| 水平 | 因素 | |||

|---|---|---|---|---|

| h/mm | D1/mm | D2/mm | α/(°) | |

| 1 | 3 | 6 | 6 | 1 |

| 2 | 6 | 10.5 | 9 | 6 |

| 3 | 9 | 15 | 12 | 11 |

表2 响应面试验因素与水平

Table 2 Analytical factors and levels for response surface methodology

| 水平 | 因素 | |||

|---|---|---|---|---|

| h/mm | D1/mm | D2/mm | α/(°) | |

| 1 | 3 | 6 | 6 | 1 |

| 2 | 6 | 10.5 | 9 | 6 |

| 3 | 9 | 15 | 12 | 11 |

| 组号 | h/ mm | D1/ mm | D2/ mm | α/ (°) | / (mm·s-1) | F/ MPa |

|---|---|---|---|---|---|---|

| 1 | 3 | 10.5 | 9 | 1 | 1.91 | 258.4 |

| 2 | 6 | 6 | 9 | 11 | 3.10 | 253.6 |

| 3 | 6 | 10.5 | 12 | 11 | 1.65 | 250.3 |

| 4 | 9 | 10.5 | 9 | 1 | 1.46 | 251.4 |

| 5 | 6 | 10.5 | 9 | 6 | 1.88 | 251.5 |

| 6 | 6 | 6 | 12 | 6 | 2.28 | 248 |

| 7 | 9 | 15 | 9 | 6 | 1.61 | 252.1 |

| 8 | 9 | 10.5 | 12 | 6 | 1.39 | 246.1 |

| 9 | 6 | 10.5 | 9 | 6 | 2.24 | 250.3 |

| 10 | 3 | 10.5 | 6 | 6 | 2.14 | 257 |

| 11 | 6 | 10.5 | 9 | 6 | 0.98 | 253.8 |

| 12 | 6 | 15 | 12 | 6 | 2.11 | 321.7 |

| 13 | 6 | 15 | 9 | 1 | 1.68 | 366.7 |

| 14 | 6 | 15 | 6 | 6 | 0.99 | 251.2 |

| 15 | 3 | 15 | 9 | 6 | 3.94 | 253.7 |

| 16 | 6 | 10.5 | 6 | 1 | 2.13 | 259.2 |

| 17 | 9 | 10.5 | 9 | 11 | 1.76 | 258 |

| 18 | 6 | 10.5 | 9 | 6 | 2.47 | 256.7 |

| 19 | 6 | 6 | 9 | 1 | 2.14 | 252 |

| 20 | 6 | 10.5 | 9 | 6 | 1.18 | 256.3 |

| 21 | 6 | 10.5 | 6 | 11 | 0.78 | 247.8 |

| 22 | 9 | 10.5 | 6 | 6 | 1.33 | 251.4 |

| 23 | 3 | 6 | 9 | 6 | 3.67 | 255.1 |

| 24 | 6 | 15 | 9 | 11 | 0.97 | 248.5 |

| 25 | 9 | 6 | 9 | 6 | 2.84 | 260 |

| 26 | 3 | 10.5 | 9 | 11 | 2.77 | 255.9 |

| 27 | 3 | 10.5 | 12 | 6 | 2.01 | 251.2 |

| 28 | 6 | 10.5 | 12 | 1 | 1.89 | 248.2 |

| 29 | 6 | 6 | 6 | 6 | 3.24 | 256.7 |

表3 Box-Behnken 试验设计及试验结果

Table 3 Experimental design and results of Box-Behnken response surface analysis

| 组号 | h/ mm | D1/ mm | D2/ mm | α/ (°) | / (mm·s-1) | F/ MPa |

|---|---|---|---|---|---|---|

| 1 | 3 | 10.5 | 9 | 1 | 1.91 | 258.4 |

| 2 | 6 | 6 | 9 | 11 | 3.10 | 253.6 |

| 3 | 6 | 10.5 | 12 | 11 | 1.65 | 250.3 |

| 4 | 9 | 10.5 | 9 | 1 | 1.46 | 251.4 |

| 5 | 6 | 10.5 | 9 | 6 | 1.88 | 251.5 |

| 6 | 6 | 6 | 12 | 6 | 2.28 | 248 |

| 7 | 9 | 15 | 9 | 6 | 1.61 | 252.1 |

| 8 | 9 | 10.5 | 12 | 6 | 1.39 | 246.1 |

| 9 | 6 | 10.5 | 9 | 6 | 2.24 | 250.3 |

| 10 | 3 | 10.5 | 6 | 6 | 2.14 | 257 |

| 11 | 6 | 10.5 | 9 | 6 | 0.98 | 253.8 |

| 12 | 6 | 15 | 12 | 6 | 2.11 | 321.7 |

| 13 | 6 | 15 | 9 | 1 | 1.68 | 366.7 |

| 14 | 6 | 15 | 6 | 6 | 0.99 | 251.2 |

| 15 | 3 | 15 | 9 | 6 | 3.94 | 253.7 |

| 16 | 6 | 10.5 | 6 | 1 | 2.13 | 259.2 |

| 17 | 9 | 10.5 | 9 | 11 | 1.76 | 258 |

| 18 | 6 | 10.5 | 9 | 6 | 2.47 | 256.7 |

| 19 | 6 | 6 | 9 | 1 | 2.14 | 252 |

| 20 | 6 | 10.5 | 9 | 6 | 1.18 | 256.3 |

| 21 | 6 | 10.5 | 6 | 11 | 0.78 | 247.8 |

| 22 | 9 | 10.5 | 6 | 6 | 1.33 | 251.4 |

| 23 | 3 | 6 | 9 | 6 | 3.67 | 255.1 |

| 24 | 6 | 15 | 9 | 11 | 0.97 | 248.5 |

| 25 | 9 | 6 | 9 | 6 | 2.84 | 260 |

| 26 | 3 | 10.5 | 9 | 11 | 2.77 | 255.9 |

| 27 | 3 | 10.5 | 12 | 6 | 2.01 | 251.2 |

| 28 | 6 | 10.5 | 12 | 1 | 1.89 | 248.2 |

| 29 | 6 | 6 | 6 | 6 | 3.24 | 256.7 |

| 因素 | 平方和 | 自由度 | 均方差/ (mm·s-1) | F/MPa | P |

|---|---|---|---|---|---|

| 模型 | 24.62 | 14 | 1.28 | 6.95 | <0.0001 |

| A | 3.45 | 1 | 3.45 | 11.48 | <0.0001 |

| B | 3.15 | 1 | 3.15 | 11.17 | <0.0001 |

| C | 0.04 | 1 | 0.04 | 0.14 | 0.718 |

| D | 0.01 | 1 | 0.01 | 0.01 | 0.9276 |

| AB | 0.78 | 1 | 0.78 | 4.8 | 0.0201 |

| AC | 0.01 | 1 | 0.01 | 0.03 | 0.8581 |

| AD | 0.08 | 1 | 0.08 | 0.24 | 0.6304 |

| BC | 3.09 | 1 | 3.09 | 9.37 | <0.0001 |

| BD | 3.69 | 1 | 3.69 | 10.15 | <0.0001 |

| CD | 0.31 | 1 | 0.31 | 0.96 | 0.3441 |

| A2 | 3.05 | 1 | 3.05 | 9.25 | <0.0001 |

| B2 | 3.49 | 1 | 3.49 | 11.74 | <0.0001 |

| C2 | 0.27 | 1 | 0.27 | 0.85 | 0.3724 |

| D2 | 0.18 | 1 | 0.18 | 0.56 | 0.4673 |

表4 (流速均方差)响应面模型方差分析

Table 4 (Mean square deviation of flow velocity) Analysis of variance of response surface model

| 因素 | 平方和 | 自由度 | 均方差/ (mm·s-1) | F/MPa | P |

|---|---|---|---|---|---|

| 模型 | 24.62 | 14 | 1.28 | 6.95 | <0.0001 |

| A | 3.45 | 1 | 3.45 | 11.48 | <0.0001 |

| B | 3.15 | 1 | 3.15 | 11.17 | <0.0001 |

| C | 0.04 | 1 | 0.04 | 0.14 | 0.718 |

| D | 0.01 | 1 | 0.01 | 0.01 | 0.9276 |

| AB | 0.78 | 1 | 0.78 | 4.8 | 0.0201 |

| AC | 0.01 | 1 | 0.01 | 0.03 | 0.8581 |

| AD | 0.08 | 1 | 0.08 | 0.24 | 0.6304 |

| BC | 3.09 | 1 | 3.09 | 9.37 | <0.0001 |

| BD | 3.69 | 1 | 3.69 | 10.15 | <0.0001 |

| CD | 0.31 | 1 | 0.31 | 0.96 | 0.3441 |

| A2 | 3.05 | 1 | 3.05 | 9.25 | <0.0001 |

| B2 | 3.49 | 1 | 3.49 | 11.74 | <0.0001 |

| C2 | 0.27 | 1 | 0.27 | 0.85 | 0.3724 |

| D2 | 0.18 | 1 | 0.18 | 0.56 | 0.4673 |

| 因素 | 平方和 | 自由度 | 均方差/ (mm·s-1) | F/ MPa | P |

|---|---|---|---|---|---|

| 模型 | 16808.17 | 24 | 900.34 | 287.09 | <0.0001 |

| A | 6 | 1 | 6 | 0.7464 | 0.4363 |

| B | 3003.04 | 1 | 3003.04 | 373.42 | <0.0001 |

| C | 18.06 | 1 | 18.06 | 2.25 | 0.2083 |

| D | 21.62 | 1 | 21.62 | 2.69 | 0.1764 |

| AB | 10.56 | 1 | 10.56 | 1.31 | 0.3157 |

| AC | 0.0625 | 1 | 0.0625 | 0.0078 | 0.934 |

| AD | 20.7 | 1 | 20.7 | 2.57 | 0.1839 |

| BC | 2568.16 | 1 | 2568.16 | 295 | <0.0001 |

| BD | 3588.01 | 1 | 3588.01 | 446.16 | <0.0001 |

| CD | 45.56 | 1 | 45.56 | 5.67 | 0.076 |

| A2 | 8.39 | 1 | 8.39 | 1.04 | 0.3648 |

| B2 | 2084.94 | 1 | 2084.94 | 259.26 | <0.0001 |

| C2 | 181.89 | 1 | 181.89 | 22.62 | 0.0089 |

| D2 | 75.25 | 1 | 75.25 | 9.36 | 0.0377 |

| A2B | 1967.15 | 1 | 1967.15 | 229.74 | <0.0001 |

| A2C | 0.845 | 1 | 0.845 | 0.1051 | 0.7621 |

| A2D | 22.44 | 1 | 22.44 | 2.79 | 0.1701 |

| AB2 | 8.4 | 1 | 8.40 | 1.05 | 0.3644 |

| AC2 | 4.2 | 1 | 4.20 | 0.5229 | 0.5096 |

| B2C | 617.76 | 1 | 617.76 | 76.82 | 0.0009 |

| B2D | 1939.16 | 1 | 1939.16 | 228.96 | <0.0001 |

| BC2 | 214.24 | 1 | 214.24 | 26.64 | 0.0067 |

| A2B2 | 350.63 | 1 | 350.63 | 43.6 | 0.0027 |

| A2C2 | 39.69 | 1 | 39.69 | 4.94 | 0.0905 |

表5 (成形载荷)响应面模型方差分析

Table 5 (Forming load) Analysis of variance of response surface model

| 因素 | 平方和 | 自由度 | 均方差/ (mm·s-1) | F/ MPa | P |

|---|---|---|---|---|---|

| 模型 | 16808.17 | 24 | 900.34 | 287.09 | <0.0001 |

| A | 6 | 1 | 6 | 0.7464 | 0.4363 |

| B | 3003.04 | 1 | 3003.04 | 373.42 | <0.0001 |

| C | 18.06 | 1 | 18.06 | 2.25 | 0.2083 |

| D | 21.62 | 1 | 21.62 | 2.69 | 0.1764 |

| AB | 10.56 | 1 | 10.56 | 1.31 | 0.3157 |

| AC | 0.0625 | 1 | 0.0625 | 0.0078 | 0.934 |

| AD | 20.7 | 1 | 20.7 | 2.57 | 0.1839 |

| BC | 2568.16 | 1 | 2568.16 | 295 | <0.0001 |

| BD | 3588.01 | 1 | 3588.01 | 446.16 | <0.0001 |

| CD | 45.56 | 1 | 45.56 | 5.67 | 0.076 |

| A2 | 8.39 | 1 | 8.39 | 1.04 | 0.3648 |

| B2 | 2084.94 | 1 | 2084.94 | 259.26 | <0.0001 |

| C2 | 181.89 | 1 | 181.89 | 22.62 | 0.0089 |

| D2 | 75.25 | 1 | 75.25 | 9.36 | 0.0377 |

| A2B | 1967.15 | 1 | 1967.15 | 229.74 | <0.0001 |

| A2C | 0.845 | 1 | 0.845 | 0.1051 | 0.7621 |

| A2D | 22.44 | 1 | 22.44 | 2.79 | 0.1701 |

| AB2 | 8.4 | 1 | 8.40 | 1.05 | 0.3644 |

| AC2 | 4.2 | 1 | 4.20 | 0.5229 | 0.5096 |

| B2C | 617.76 | 1 | 617.76 | 76.82 | 0.0009 |

| B2D | 1939.16 | 1 | 1939.16 | 228.96 | <0.0001 |

| BC2 | 214.24 | 1 | 214.24 | 26.64 | 0.0067 |

| A2B2 | 350.63 | 1 | 350.63 | 43.6 | 0.0027 |

| A2C2 | 39.69 | 1 | 39.69 | 4.94 | 0.0905 |

| 凹模 | 力学性能 | |||

|---|---|---|---|---|

| 拉伸方向 | σs/MPa | Rm/MPa | δ/% | |

| 平面 | z轴 | 159 | 292 | 11.6 |

| x轴 | 235 | 332 | 7.4 | |

| 优化 | z轴 | 192 | 313 | 9.5 |

| x轴 | 218 | 332 | 8.5 | |

表6 沿z轴和x轴方向的拉伸性能

Table 6 Tensile properties along z and x directions

| 凹模 | 力学性能 | |||

|---|---|---|---|---|

| 拉伸方向 | σs/MPa | Rm/MPa | δ/% | |

| 平面 | z轴 | 159 | 292 | 11.6 |

| x轴 | 235 | 332 | 7.4 | |

| 优化 | z轴 | 192 | 313 | 9.5 |

| x轴 | 218 | 332 | 8.5 | |

| [1] |

|

| [2] |

|

| [3] |

doi: 10.1016/S1003-6326(19)64984-8 |

| [4] |

陈亮, 刘荣忠, 郭锐, 等. 扭曲尾翼弹箭气动外形多目标优化[J]. 兵工学报, 2016, 37(7):1187-1193.

doi: 10.3969/j.issn.1000-1093.2016.07.005 |

|

|

|

| [5] |

鲍键, 李全安, 陈晓亚, 等. 挤压镁合金的研究进展[J]. 材料导报, 2022, 36(10):108-119.

|

|

|

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

郑建新, 刘威成, 段玉涛. 7075铝合金二维超声挤压加工表面质量影响因素及其交互作用研究[J]. 兵工学报, 2017, 38(6):1231-1238.

doi: 10.3969/j.issn.1000-1093.2017.06.024 |

|

|

|

| [10] |

张吉银, 姚倡锋, 谭靓, 等. 喷丸强化残余应力对疲劳性能和变形控制影响研究进展[J]. 机械工程学报, 2022, 58(1):1-15.

|

|

|

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

刘惠, 刘腾飞, 陈宗强, 等. 基于试验设计和响应曲面法的大型带筋薄壁铝型材挤压工艺优化[J]. 锻压技术, 2022, 47(5):144-152.

doi: 10.13330/j.issn.1000-3940.2022.05.022 |

|

|

|

| [15] |

周晓远, 陈文琳, 潘鹏林, 等. 空心薄壁铝型材挤压数值模拟与模具优化设计[J]. 模具工业, 2018, 44(12):58-65.

|

| [28] |

|

| [29] |

吴昂, 吴莹, 李国俊, 等. 基于响应曲面法的大型锥形件缩口成形工艺设计及多几何参数优化[J]. 机械工程学报, 2019, 55(24):83-92.

doi: 10.3901/JME.2019.24.083 |

|

doi: 10.3901/JME.2019.24.083 |

|

| [15] |

|

| [16] |

刘志文, 李落星, 符纯明, 等. 薄壁中空型材分流模挤压缺陷产生机理及出口流速精确控制[J]. 中国有色金属学报, 2021, 31(4):917-930.

|

|

|

|

| [17] |

管志新. 铝挤压分流模结构优化及配套切刀设计[D]. 烟台: 烟台大学, 2022.

|

|

|

|

| [18] |

朱俊瑞. 铝型材平面分流挤压模具分流桥的结构研究[D]. 烟台: 烟台大学, 2021.

|

|

|

|

| [19] |

祝志荣, 洁琼, 邓汝荣. 大型铝合金矩形管分流模结构的优化改进[J]. 铝加工, 2020, 254(3):58-61.

|

|

|

|

| [20] |

姜建堂, 范丁歌, 赵熊爔, 等. 大型铝合金构件制造全过程残余应力预测与控制[J]. 中国材料进展, 2022, 41(11):899-908.

|

|

|

|

| [21] |

高伟, 王雷刚, 黄瑶, 等. 基于Deform 3D的方管挤压模模桥结构优化研究[J]. 轻合金加工技术, 2017, 45(8):40-45.

|

|

|

|

| [22] |

王少华, 刘惠, 陈宗强, 等. 大型带筋薄壁圆管铝型材挤压成形数值模拟[J]. 锻压技术, 2022, 47(4):181-189.

doi: 10.13330/j.issn.1000-3940.2022.04.025 |

|

|

|

| [23] |

|

| [24] |

赵震, 沈大为, 曹益旗, 等. 基于卷积神经网络的板料挤压成形力预测[J]. 锻压技术, 2021, 46(9):76-84.

doi: 10.13330/j.issn.1000-3940.2021.09.008 |

|

|

|

| [25] |

徐宁宁, 孙朝阳, 钱凌云, 等. 镁合金板形件扭-挤成形载荷的主应力法求解模型[J]. 机械工程学报, 2021, 57(4):73-82.

doi: 10.3901/JME.2021.04.073 |

|

doi: 10.3901/JME.2021.04.073 |

|

| [26] |

颜宽然. 铝合金挤压型、棒材形状系数函数研究[J]. 轻合金加工技术, 1992, 16(11):31-34.

|

|

|

|

| [27] |

|

| [28] |

刘乾坤, 赵鹏, 吴定雨, 等. 基于主应力法对六面顶压机密封边受力的分析[J]. 超硬材料工程, 2019, 31(6):16-18.

|

| [1] | 吉新博, 卢卫建, 吕琛, 王玺, 廉政, 何丽. 不同冲击载荷下典型路面结构的动态弯沉响应[J]. 兵工学报, 2024, 45(1): 299-311. |

| [2] | 柳锦春, 王钰颖, 孙妮. 喷涂聚脲加固双向砌体墙抗燃气爆炸性能数值分析[J]. 兵工学报, 2023, 44(S1): 138-143. |

| [3] | 乔扬, 赵至诚, 谢晶, 陈鹏万. SLM钛合金蜂窝结构的面内压缩力学行为[J]. 兵工学报, 2023, 44(3): 629-637. |

| [4] | 袁名正, 潘腾, 卞晓兵, 杨磊, 周宏元, 黄广炎, 张宏. 曲面型纤维复材防护掩体在爆炸冲击波下的响应特性[J]. 兵工学报, 2023, 44(12): 3909-3920. |

| [5] | 王昊, 徐斌, 王舒, 徐永杰, 吴浩. 盒型芯层波纹板的抗爆炸冲击防护性能[J]. 兵工学报, 2023, 44(12): 3687-3695. |

| [6] | 韩佳彤, 王昕, 张磊, 李振, 王鹏飞, 赵振宇, 卢天健. 泡沫子弹冲击下预制圆孔Q235钢板的动态响应与破坏机理[J]. 兵工学报, 2023, 44(12): 3654-3666. |

| [7] | 喻争, 王舒, 董方栋, 郑志军, 崔世堂, 张永亮. 分段杆弹的梯度化设计[J]. 兵工学报, 2022, 43(9): 2300-2306. |

| [8] | 彭泽宇, 颜培. 低温切削奥氏体304不锈钢残余应力研究[J]. 兵工学报, 2019, 40(6): 1271-1276. |

| [9] | 孙全兆, 杨国来, 王鹏, 葛建立, 谢润. 某大口径榴弹炮弹带挤进过程数值模拟研究[J]. 兵工学报, 2015, 36(2): 206-213. |

| [10] | 李萍, 章凯, 薛克敏, 王晓溪. 新型药型罩温压扭成形模拟与实验研究[J]. 兵工学报, 2012, 33(4): 437-442. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4