主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2025, Vol. 46 ›› Issue (6): 240371-.doi: 10.12382/bgxb.2024.0371

王凯1, 郑孟伟2, 巩浩1,3,4,*( ), 刘检华1,3,4, 赵有磊2, 刘少丽1,3,4

), 刘检华1,3,4, 赵有磊2, 刘少丽1,3,4

收稿日期:2024-05-15

上线日期:2025-06-28

通讯作者:

WANG Kai1, ZHENG Mengwei2, GONG Hao1,3,4,*( ), LIU Jianhua1,3,4, ZHAO Youlei2, LIU Shaoli1,3,4

), LIU Jianhua1,3,4, ZHAO Youlei2, LIU Shaoli1,3,4

Received:2024-05-15

Online:2025-06-28

摘要:

金属密封圈在各种机械产品中广泛应用,其主要依靠粗糙表面弹塑性接触变形实现密封。针对传统的粗糙表面微观接触有限元仿真方法计算效率低、弹塑性接触变形收敛困难的问题,提出有限元-边界元耦合的金属密封圈弹塑性微观接触计算方法。建立金属密封结构宏观有限元模型,精确求解密封面接触应力分布;建立密封面微观形貌,在弹塑性接触等效的基础上,以宏观接触应力分布作为边界条件,提出残余形变量和残余应力场叠加的弹塑性接触计算边界元方法,求解粗糙表面弹塑性变形的接触状态。同时,对密封面微观接触等效建模方法进行验证,并与粗糙表面微观接触的有限元仿真方法进行对比,证明所提有限元-边界元耦合仿真方法与有限元方法计算精度相当,但是计算效率提高了近8倍。采用四联通网格模型求解密封面泄漏通道,作为密封性能评价指标,系统研究材料参数、接触应力、表面粗糙度、粗糙表面参数等因素对金属圈密封性能的影响规律。搭建密封实验台对金属圈的泄漏率进行测量,获得了金属圈实际泄漏率随法向载荷的变化规律,仿真结果与实验规律趋势一致。

中图分类号:

王凯, 郑孟伟, 巩浩, 刘检华, 赵有磊, 刘少丽. 金属圈弹塑性接触计算与密封性能分析[J]. 兵工学报, 2025, 46(6): 240371-.

WANG Kai, ZHENG Mengwei, GONG Hao, LIU Jianhua, ZHAO Youlei, LIU Shaoli. Elastic-plastic Contact Calculation and Sealing Performance Analysis of Metal Sealing Ring[J]. Acta Armamentarii, 2025, 46(6): 240371-.

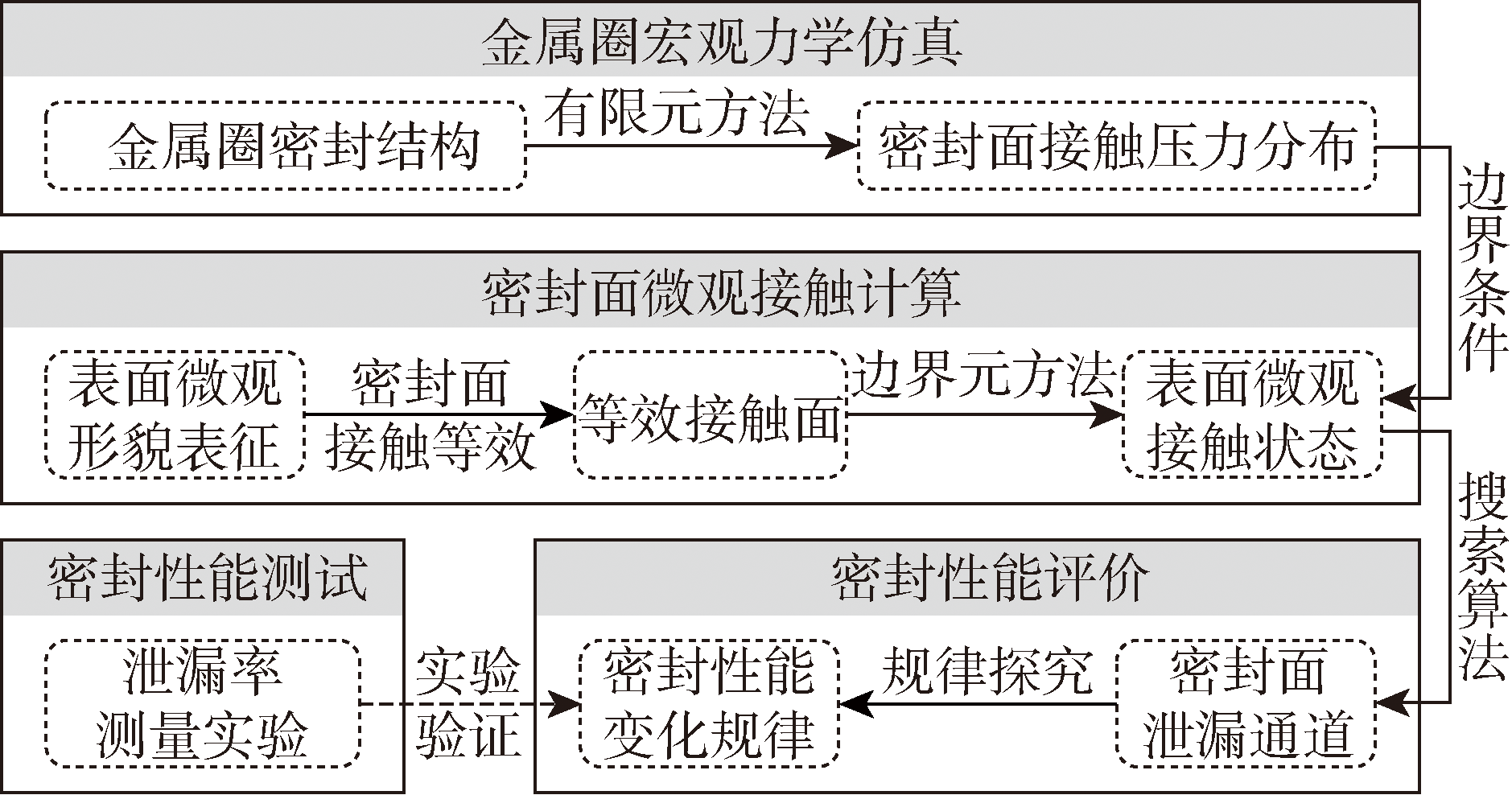

图2 有限元-边界元耦合的金属密封圈接触计算与密封性能分析流程

Fig.2 Flowchart of contact calculation and sealing performance analysis of metal sealing ring based on coupled finite element-boundary element method

| 材料 | 屈服强度/ MPa | 弹性模量/ GPa | 切线模量/ MPa | 泊松比 |

|---|---|---|---|---|

| 30CrMnSiA | 835 | 206 | 2553 | 0.30 |

| TC11钛合金 | 900 | 107.8 | 1 814 | 0.34 |

| T2紫铜 | 70 | 108 | 868 | 0.35 |

表1 不同材料的材料属性

Table 1 Material properties of different materials

| 材料 | 屈服强度/ MPa | 弹性模量/ GPa | 切线模量/ MPa | 泊松比 |

|---|---|---|---|---|

| 30CrMnSiA | 835 | 206 | 2553 | 0.30 |

| TC11钛合金 | 900 | 107.8 | 1 814 | 0.34 |

| T2紫铜 | 70 | 108 | 868 | 0.35 |

| 等效前后 | 弹性模量/ GPa | 泊松比 | 屈服强度/ MPa | 切线模量/ MPa | |

|---|---|---|---|---|---|

| 等效前 | 表面1 | 120 | 0.3 | 1200 | 10000 |

| 表面2 | 120 | 0.3 | 500 | 10000 | |

| 等效后 | 60 | 0.3 | 500 | 10000 | |

表2 等效前后的材料属性

Table 2 Material properties before and after equivalence

| 等效前后 | 弹性模量/ GPa | 泊松比 | 屈服强度/ MPa | 切线模量/ MPa | |

|---|---|---|---|---|---|

| 等效前 | 表面1 | 120 | 0.3 | 1200 | 10000 |

| 表面2 | 120 | 0.3 | 500 | 10000 | |

| 等效后 | 60 | 0.3 | 500 | 10000 | |

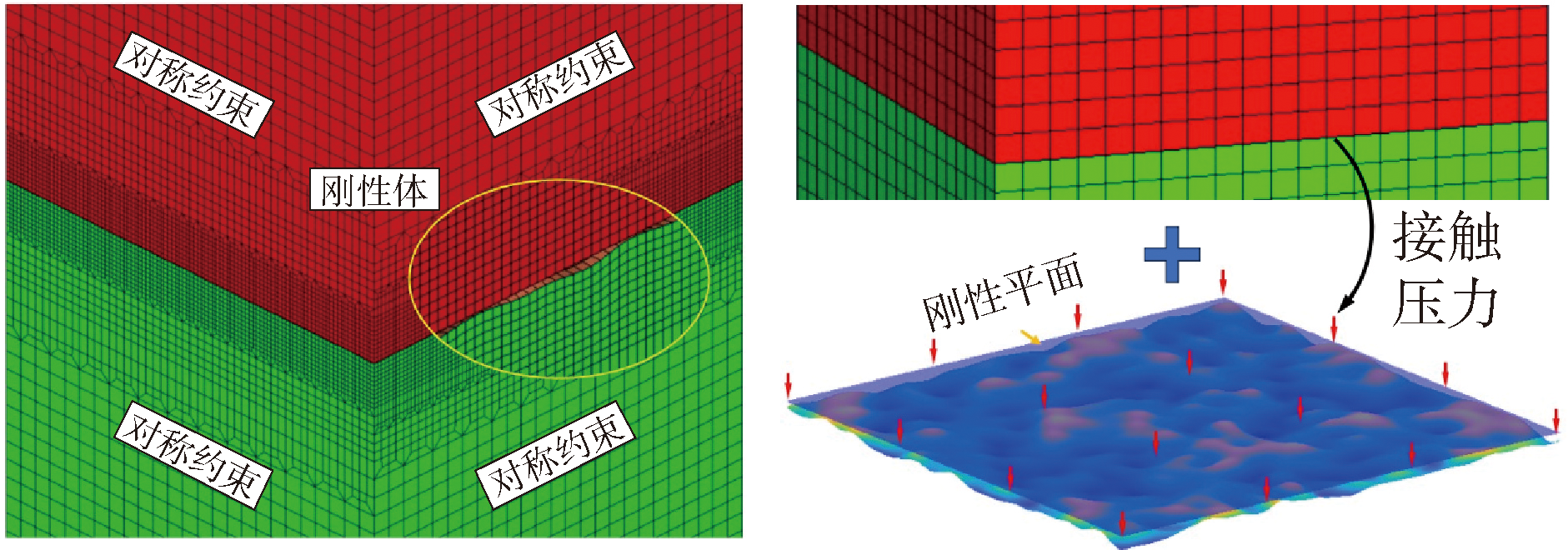

图12 有限元方法(左)和有限元-边界元耦合方法(右)的接触计算示意图

Fig.12 Contact calculation diagrams of finite element method(left) and finite element-boundary element coupling method(right)

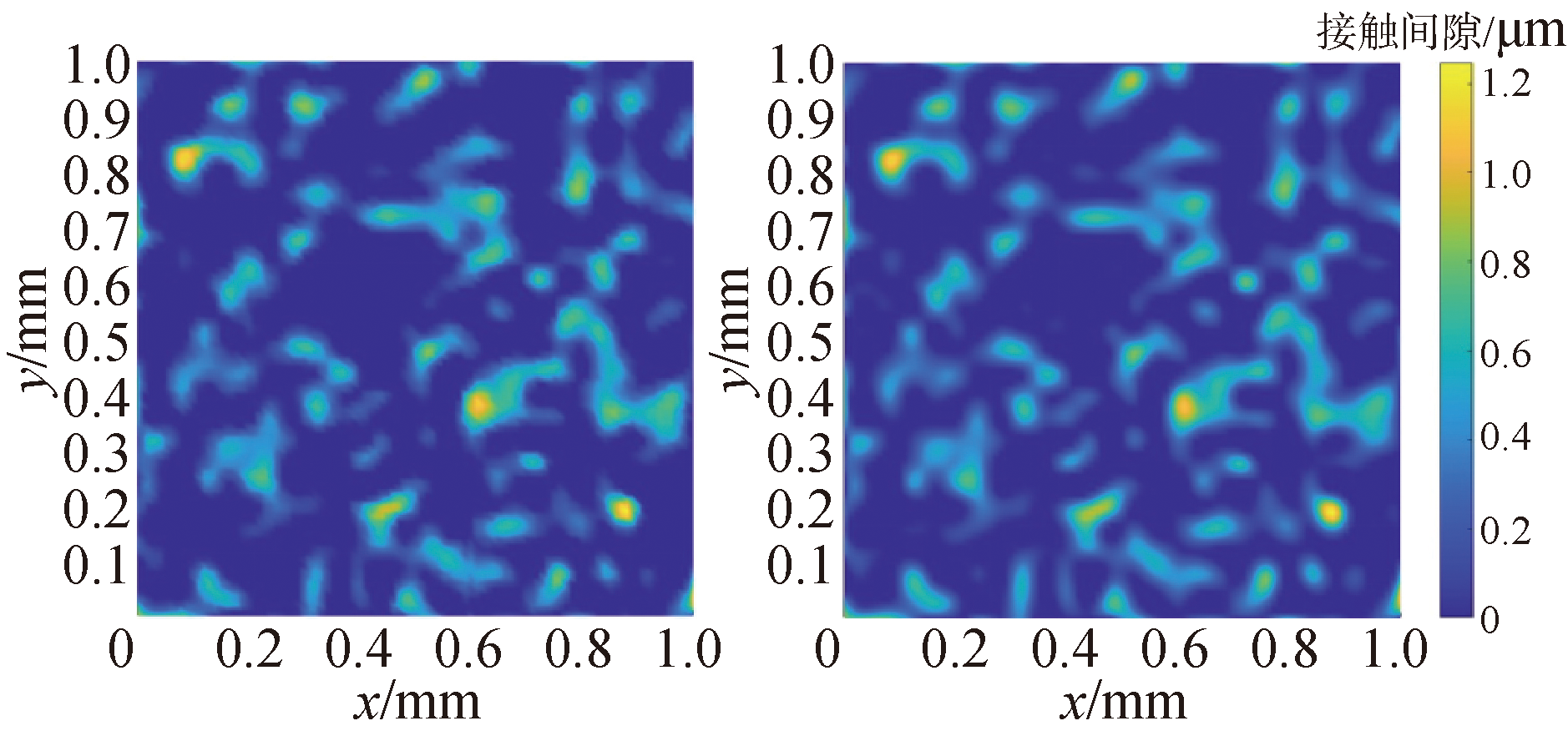

图13 有限元方法(左)和有限元-边界元耦合方法(右)的接触间隙分布计算结果

Fig.13 Calculated results of contact gap distribution obtained by finite element method(left)and finite element-boundary elementcoupling method(right)

| [1] |

段浩, 陈晖, 翟兆阳, 等. 基于支持向量机的氢混天然气发动机性能预测[J]. 兵工学报, 2022, 43(5):1002-1011.

doi: 10.12382/bgxb.2021.0199 |

|

doi: 10.12382/bgxb.2021.0199 |

|

| [2] |

陈庆, 陈利强, 康博. 往复运动橡胶O形密封圈密封机制及其特性的研究[J]. 润滑与密封, 2011, 36(6):76-78.

|

|

|

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

李远超. 金属橡胶密封件温度特性研究及专用试验台研制[D]. 哈尔滨: 哈尔滨工业大学, 2014.

|

|

|

|

| [7] |

|

| [8] |

|

| [9] |

张彤, 李德才, 李艳文. 磁性液体密封与迷宫密封组合密封的结构设计及优化[J]. 机械工程学报, 2022, 58(9):172-181.

doi: 10.3901/JME.2022.09.172 |

|

doi: 10.3901/JME.2022.09.172 |

|

| [10] |

|

| [11] |

黄伟旋, 岳婷, 林起崟, 等. 液体火箭发动机U形环密封界面优化设计[J]. 润滑与密封, 2024, 45(5):15-22.

|

|

|

|

| [12] |

|

| [13] |

傅磊, 雷学林, 章兰珠. 表面粗糙度对金属平垫泄漏率的影响[J]. 润滑与密封, 2023, 48(8):114-119.

|

|

|

|

| [14] |

李伟平, 贾占举, 路茜, 等. 金属封严环泄漏率预测方法[J]. 航空动力学报, 2019, 34(2):368-375.

|

|

|

|

| [15] |

|

| [16] |

刘检华, 张飞凯, 丁晓宇. 弹塑性粗糙表面实际接触面积演变规律研究[J]. 机械工程学报, 2021, 57(7):109-116.

doi: 10.3901/JME.2021.07.109 |

|

doi: 10.3901/JME.2021.07.109 |

|

| [17] |

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

|

| [23] |

|

| [24] |

|

| [25] |

|

| [1] | 倪蓥锋, 陈小伟. 柱形弹超高速撞击加筋板架结构的破片群特征分析[J]. 兵工学报, 2025, 46(6): 240812-. |

| [2] | 王艺臻, 尹建平, 张雪朋, 伊建亚, 李旭东. 聚能射流动态侵彻威力预测模型[J]. 兵工学报, 2025, 46(6): 240932-. |

| [3] | 陈于思, 张宁, 范军, 李兵, 王斌. 一种周向周期结构声散射快速计算方法[J]. 兵工学报, 2025, 46(5): 240291-. |

| [4] | 周迅, 王洪武, 王旭升, 王正, 曲俊峰, 孙孟勇, 潘骏. 氮化硅陶瓷微观结构的有限元建模方法[J]. 兵工学报, 2025, 46(4): 240407-. |

| [5] | 张骢, 陆俊桦, 岳明凯. 成像引信仿生复合减振结构设计与仿真[J]. 兵工学报, 2025, 46(2): 240021-. |

| [6] | 金跃, 缪馥星. 碳纤维增强复合材料多孔阵列薄壁圆管的抗冲击与吸能性能[J]. 兵工学报, 2025, 46(2): 240074-. |

| [7] | 李祥辉, 张兴渝, 胡家豪, 刘洋, 马伯翰, 王永刚, 蒋招绣. AISI 4340钢靶大塑性模型及断裂起始模型参数研究[J]. 兵工学报, 2025, 46(1): 231210-. |

| [8] | 高茂国, 刘睿, 郭岩松, 耿恒恒, 陈鹏万. HfZrTiTaAl系高熵合金动态变形、损伤及破坏行为[J]. 兵工学报, 2025, 46(1): 231183-. |

| [9] | 孔祥清, 李若男, 常雅慧, 付莹. 泡沫填充负泊松比蜂窝夹层结构的抗爆性能数值模拟[J]. 兵工学报, 2024, 45(9): 3091-3104. |

| [10] | 吴春尧, 宋春明, 李干, 徐观淦, 韩彤. 高压膜片破膜压力阈值及影响因素[J]. 兵工学报, 2024, 45(9): 3307-3316. |

| [11] | 左铭朔, 徐豫新, 李永鹏, 李旭东, 郭德龙, 杨祥. 内爆载荷下民机用定向泄爆容器结构的动态响应[J]. 兵工学报, 2024, 45(7): 2383-2392. |

| [12] | 贾晶晶, 张治民, 于建民, 薛勇, 吴昂. 基于响应面法的轻质尾翼均匀挤压成形数值模拟及模具结构优化[J]. 兵工学报, 2024, 45(6): 1824-1839. |

| [13] | 杨拓, 熊诗辉, 汪靖程, 赵象润, 温玉全. 火工分离螺母作动噪声的预示和解耦[J]. 兵工学报, 2024, 45(3): 763-773. |

| [14] | 项新梅, 罗林林, 符祖书, 何世珠. 梯度模式对Miura-ori超材料力学性能影响的研究[J]. 兵工学报, 2024, 45(2): 618-627. |

| [15] | 陶子豪, 李祥龙, 胡启文, 王建国. 掏槽爆破成腔空孔效应数值模拟研究与分析[J]. 兵工学报, 2024, 45(12): 4246-4258. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4