主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (2): 395-406.doi: 10.12382/bgxb.2022.0740

薛浩1, 王涛1, 黄广炎1,2,*( ), 崔欣雨1, 韩洪伟3

), 崔欣雨1, 韩洪伟3

收稿日期:2022-08-25

上线日期:2024-02-29

通讯作者:

基金资助:

XUE Hao1, WANG Tao1, HUANG Guangyan1,2,*( ), CUI Xinyu1, HAN Hongwei3

), CUI Xinyu1, HAN Hongwei3

Received:2022-08-25

Online:2024-02-29

摘要:

为探索增材制造316L不锈钢球形破片的弹道性能,采用选择性激光熔化(Selective Laser Melting,SLM)技术制造316L不锈钢材料毛坯,通过机加工、抛光等操作得到了直径12mm的增材制造316L不锈钢球形破片。开展打印态316L不锈钢材料的显微计算机断层扫描(Computed Tomography, CT)和静动态力学试验研究,获得了打印态316L不锈钢在材料沉积方向的Johnson-Cook(JC)模型参数,进行了增材制造和传统冷轧工艺制造的316L不锈钢球形破片侵彻6mm厚Q235钢靶的弹道试验。研究结果表明:增材制造球形破片的弹道极限速度比传统冷轧制造破片低2.5%左右,弹道性能有小幅提升,暗示了增材制造工艺用于制造战斗部预制破片的潜力;开展的数值仿真研究获得了与试验结果一致的剪切冲塞穿靶机理,仿真与试验穿靶速度数据比较吻合,弹道极限速度误差仅为1.4%左右,仿真结果也表明JC模型用于描述增材制造316L不锈钢材料穿靶行为的可行性。

中图分类号:

薛浩, 王涛, 黄广炎, 崔欣雨, 韩洪伟. 增材制造316L不锈钢球形破片的弹道性能[J]. 兵工学报, 2024, 45(2): 395-406.

XUE Hao, WANG Tao, HUANG Guangyan, CUI Xinyu, HAN Hongwei. Ballistic Performance of Additively Manufactured 316L Stainless Steel Spherical Fragments[J]. Acta Armamentarii, 2024, 45(2): 395-406.

| 元素 | C | Cr | Fe | Mo | Ni | Mn |

|---|---|---|---|---|---|---|

| 标准含量/% | ≤0.03 | 16~18 | 其余 | 2~3 | 12~15 | ≤2 |

| 实际含量/% | 0.022 | 17.16 | 其余 | 2.71 | 12.2 | 1.45 |

表1 增材制造316L不锈钢的化学组分

Table 1 Chemical composition of additively manufactured 316L stainless steel

| 元素 | C | Cr | Fe | Mo | Ni | Mn |

|---|---|---|---|---|---|---|

| 标准含量/% | ≤0.03 | 16~18 | 其余 | 2~3 | 12~15 | ≤2 |

| 实际含量/% | 0.022 | 17.16 | 其余 | 2.71 | 12.2 | 1.45 |

| 激光 能量/W | 扫描 层厚/mm | 扫描速度/ (mm·s-1) | 扫描 角度/(°) | 扫描 策略 | 扫描 间距/mm |

|---|---|---|---|---|---|

| 295 | 0.04 | 1000 | 135, 180, 225循环 | Z字形 | 0.08 |

表2 增材制造316L不锈钢的打印参数

Table 2 Printing process parameters of additively manufactured 316L stainless steel

| 激光 能量/W | 扫描 层厚/mm | 扫描速度/ (mm·s-1) | 扫描 角度/(°) | 扫描 策略 | 扫描 间距/mm |

|---|---|---|---|---|---|

| 295 | 0.04 | 1000 | 135, 180, 225循环 | Z字形 | 0.08 |

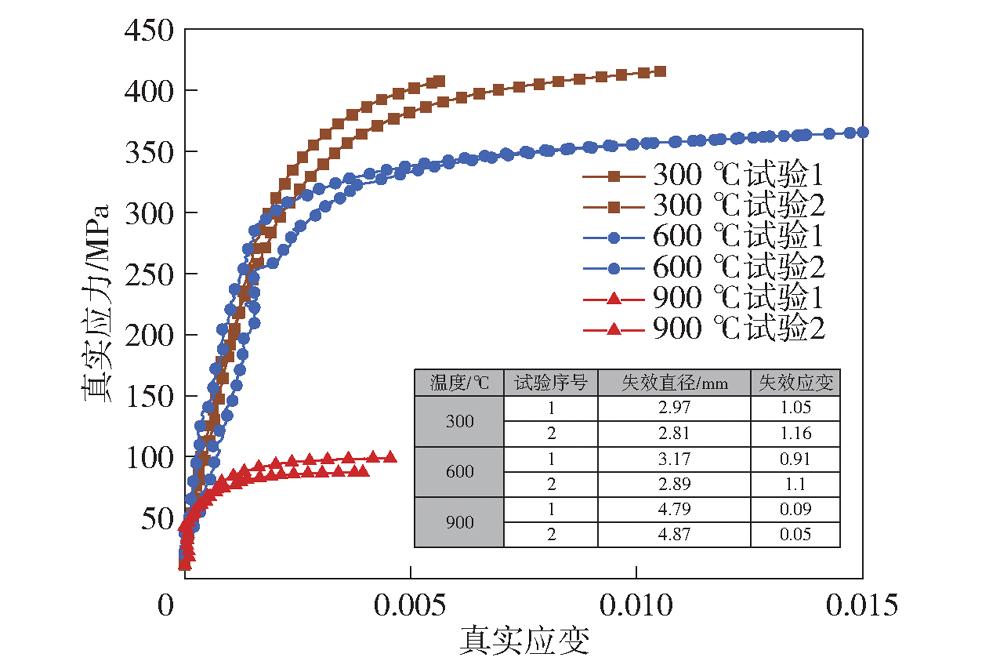

图11 不同温度下在静态拉伸试验中得到的光滑圆棒真实应力-应变

Fig.11 True stress vs. true strain curves of smooth round bars obtained in static tensile tests at different temperatures

| 破片 | 编号 | vi/(m·s-1) | vr/(m·s-1) | 穿靶状态 |

|---|---|---|---|---|

| A1 | 1025 | 462 | 穿透 | |

| A2 | 1011 | 450 | 穿透 | |

| A3 | 702 | 227 | 穿透 | |

| A4 | 628 | 174 | 穿透 | |

| A5 | 609 | 163 | 穿透 | |

| A6 | 577 | 141 | 穿透 | |

| A7 | 558 | 145 | 穿透 | |

| A8 | 540 | 133 | 穿透 | |

| A9 | 537 | 74 | 穿透 | |

| A10 | 537 | 112 | 穿透 | |

| 冷轧破片 | A11 | 532 | 23 | 穿透 |

| A12 | 529 | 59 | 穿透 | |

| A13 | 517 | 0 | 嵌入 | |

| A14 | 515 | 0 | 嵌入 | |

| A15 | 509 | 0 | 嵌入 | |

| A16 | 508 | 0 | 嵌入 | |

| A17 | 487 | 0 | 嵌入 | |

| A18 | 477 | 0 | 嵌入 | |

| A19 | 472 | 0 | 嵌入 | |

| A20 | 449 | 0 | 嵌入 | |

| A21 | 400 | 0 | 嵌入 | |

| B1 | 1002 | 485 | 穿透 | |

| B2 | 951 | 448 | 穿透 | |

| B3 | 646 | 185 | 穿透 | |

| B4 | 613 | 167 | 穿透 | |

| B5 | 594 | 131 | 穿透 | |

| B6 | 552 | 110 | 穿透 | |

| B7 | 546 | 97 | 穿透 | |

| B8 | 542 | 156 | 穿透 | |

| B9 | 523 | 92 | 穿透 | |

| 增材破片 | B10 | 504 | 0 | 嵌入 |

| B11 | 496 | 0 | 嵌入 | |

| B12 | 492 | 0 | 嵌入 | |

| B13 | 477 | 0 | 嵌入 | |

| B14 | 474 | 0 | 嵌入 | |

| B15 | 453 | 0 | 嵌入 | |

| B16 | 437 | 0 | 嵌入 | |

| B17 | 434 | 0 | 嵌入 | |

| B18 | 433 | 0 | 嵌入 | |

| B19 | 431 | 0 | 嵌入 |

表3 弹道试验结果

Table 3 Ballistic test results

| 破片 | 编号 | vi/(m·s-1) | vr/(m·s-1) | 穿靶状态 |

|---|---|---|---|---|

| A1 | 1025 | 462 | 穿透 | |

| A2 | 1011 | 450 | 穿透 | |

| A3 | 702 | 227 | 穿透 | |

| A4 | 628 | 174 | 穿透 | |

| A5 | 609 | 163 | 穿透 | |

| A6 | 577 | 141 | 穿透 | |

| A7 | 558 | 145 | 穿透 | |

| A8 | 540 | 133 | 穿透 | |

| A9 | 537 | 74 | 穿透 | |

| A10 | 537 | 112 | 穿透 | |

| 冷轧破片 | A11 | 532 | 23 | 穿透 |

| A12 | 529 | 59 | 穿透 | |

| A13 | 517 | 0 | 嵌入 | |

| A14 | 515 | 0 | 嵌入 | |

| A15 | 509 | 0 | 嵌入 | |

| A16 | 508 | 0 | 嵌入 | |

| A17 | 487 | 0 | 嵌入 | |

| A18 | 477 | 0 | 嵌入 | |

| A19 | 472 | 0 | 嵌入 | |

| A20 | 449 | 0 | 嵌入 | |

| A21 | 400 | 0 | 嵌入 | |

| B1 | 1002 | 485 | 穿透 | |

| B2 | 951 | 448 | 穿透 | |

| B3 | 646 | 185 | 穿透 | |

| B4 | 613 | 167 | 穿透 | |

| B5 | 594 | 131 | 穿透 | |

| B6 | 552 | 110 | 穿透 | |

| B7 | 546 | 97 | 穿透 | |

| B8 | 542 | 156 | 穿透 | |

| B9 | 523 | 92 | 穿透 | |

| 增材破片 | B10 | 504 | 0 | 嵌入 |

| B11 | 496 | 0 | 嵌入 | |

| B12 | 492 | 0 | 嵌入 | |

| B13 | 477 | 0 | 嵌入 | |

| B14 | 474 | 0 | 嵌入 | |

| B15 | 453 | 0 | 嵌入 | |

| B16 | 437 | 0 | 嵌入 | |

| B17 | 434 | 0 | 嵌入 | |

| B18 | 433 | 0 | 嵌入 | |

| B19 | 431 | 0 | 嵌入 |

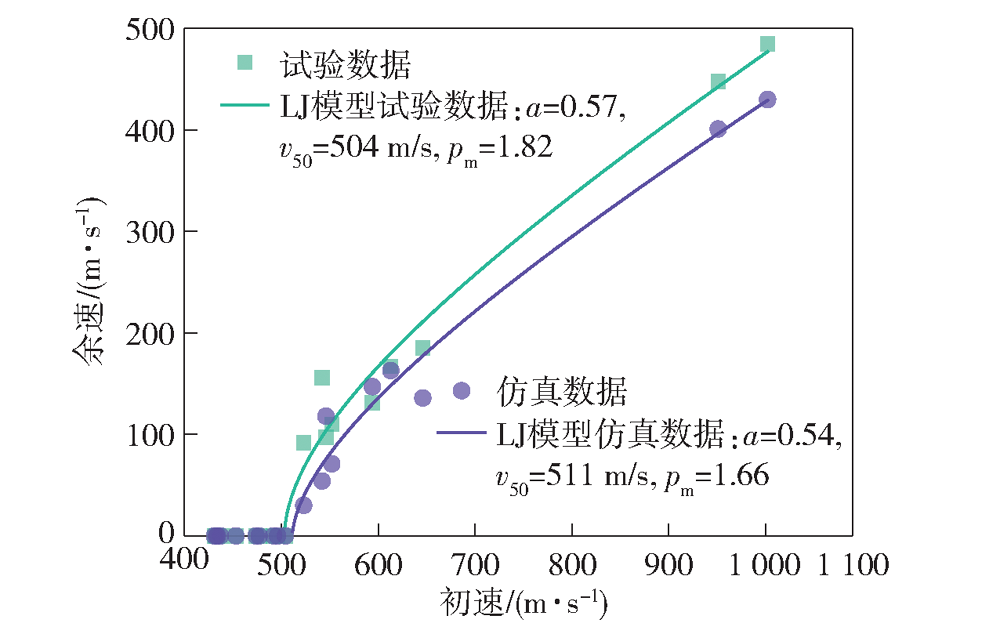

| 工艺 | a | v50/(m·s-1) | pm | R2/% |

|---|---|---|---|---|

| 冷轧 | 0.50 | 517 | 2.16 | 97.9 |

| 增材 | 0.57 | 504 | 1.82 | 98.3 |

表4 两种工艺制造破片的拟合结果

Table 4 Fitting results for two types of fragment

| 工艺 | a | v50/(m·s-1) | pm | R2/% |

|---|---|---|---|---|

| 冷轧 | 0.50 | 517 | 2.16 | 97.9 |

| 增材 | 0.57 | 504 | 1.82 | 98.3 |

| ρ/ (kg·m-3) | E/ GPa | u | Cp/ (J·kg-1·K-1) | Tr/ K | Tm/ K | / s-1 |

|---|---|---|---|---|---|---|

| 7800 | 200 | 0.3 | 469 | 300 | 1795 | 1 |

| A/MPa | B/MPa | n | C | m | D1 | D2 |

| 410 | 20 | 0.08 | 0.1 | 0.55 | 0.3 | 0.9 |

| D3 | D4 | D5 | ||||

| 2.8 | 0 | 0 |

表5 Q235钢靶板的JC材料参数[26]

Table 5 JC material parameters of Q235 steel target plate[26]

| ρ/ (kg·m-3) | E/ GPa | u | Cp/ (J·kg-1·K-1) | Tr/ K | Tm/ K | / s-1 |

|---|---|---|---|---|---|---|

| 7800 | 200 | 0.3 | 469 | 300 | 1795 | 1 |

| A/MPa | B/MPa | n | C | m | D1 | D2 |

| 410 | 20 | 0.08 | 0.1 | 0.55 | 0.3 | 0.9 |

| D3 | D4 | D5 | ||||

| 2.8 | 0 | 0 |

| C0/(m·s-1) | S1 | γ0 | α |

|---|---|---|---|

| 4578 | 1.36 | 1.67 | 0.45 |

表6 316L不锈钢破片和Q235钢靶板的状态方程参数[27]

Table 6 The equation of state parameters of 316L stainless steel fragments and Q235 steel target plate[27]

| C0/(m·s-1) | S1 | γ0 | α |

|---|---|---|---|

| 4578 | 1.36 | 1.67 | 0.45 |

图17 仿真和试验中增材破片初速和余速关系曲线

Fig.17 Relationship between the initial velocity and residual velocity of additively manufactured fragments in simulation and test

| [1] |

辛甜, 韩庆. 钢破片侵彻靶板弹道极限速度研究[J]. 科学技术与工程, 2012(2): 264-268.

|

|

|

|

| [2] |

刘铁磊, 徐豫新, 王晓锋, 等. 钨合金球形破片侵彻低碳钢的弹道极限速度计算模型[J]. 兵工学报, 2022, 43(4): 768-779.

|

|

doi: 10.12382/bgxb.2021.0448 |

|

| [3] |

吕珮毅, 张允航, 张曌. 破片形状, 着靶姿态对侵彻多层靶影响的数据模拟研究[J]. 国外电子测量技术, 2021, 40(1):27-31.

|

|

|

|

| [4] |

张家莲, 李发亮, 张海军. 选区激光熔化技术制备金属材料研究进展[J]. 激光与光电子学进展, 2019, 56(10):35-44.

|

|

|

|

| [5] |

|

| [6] |

郭美红. SLM加工的预控破片研究[D]. 南京: 南京理工大学, 2018.

|

|

|

|

| [7] |

Additive manufacturing—general principles—fundamentals and vocabulary: ISO/ASTM 52900:2021[J]. Vernier, Geneva, Switzerland:ISO, 2021.

|

| [8] |

doi: 10.3390/ma10060672 URL |

| [9] |

doi: 10.1016/J.ENG.2017.05.012 URL |

| [10] |

doi: 10.1016/j.ijimpeng.2017.11.011 URL |

| [11] |

doi: 10.1016/j.dt.2014.08.004 |

| [12] |

doi: 10.1515/mms-2016-0027 URL |

| [13] |

doi: 10.1016/j.mechmat.2013.12.001 URL |

| [14] |

doi: 10.1016/j.msea.2022.142683 URL |

| [15] |

doi: 10.1016/j.jmrt.2022.04.116 URL |

| [16] |

doi: 10.1016/j.msea.2015.05.073 URL |

| [17] |

余小鲁, 汪太平. 造孔剂含量对粉末冶金不锈钢多孔材料孔隙率和抗压强度的影响[J]. 机械工程材料, 2012, 36(7): 60-62.

|

|

|

|

| [18] |

doi: 10.1016/j.msea.2013.04.041 URL |

| [19] |

doi: 10.1016/j.ijimpeng.2005.06.007 URL |

| [20] |

doi: 10.1016/j.msea.2016.04.083 URL |

| [21] |

doi: 10.1007/s40870-016-0059-1 URL |

| [22] |

doi: 10.1016/j.proeng.2016.12.046 URL |

| [23] |

doi: 10.1115/1.3636566 URL |

| [24] |

|

| [25] |

doi: 10.1016/j.msea.2021.141808 URL |

| [26] |

doi: 10.1007/s11340-007-9110-4 URL |

| [27] |

程兴旺, 王富耻, 李树奎, 等. 不同头部形状长杆弹侵彻过程的数值模拟[J]. 兵工学报, 2007(8):930-933.

|

|

|

|

| [28] |

|

| [29] |

LS-DYNA keyword user’s manual[J]. Livermore, CA, US: Livermore Software Technology Corporation, 2003: 299-800.

|

| [30] |

陈海华, 张先锋, 熊玮, 等. WFeNiMo高熵合金动态力学行为及侵彻性能研究[J]. 力学学报, 2020, 52(5):1443-1453.

doi: 10.6052/0459-1879-20-166 |

|

|

| [1] | 袁璟, 蔺向阳, 彭洋, 檀成. 光固化含能粘合剂的设计与合成[J]. 兵工学报, 2023, 44(7): 2023-2032. |

| [2] | 王宇, 白舒乐, 王子琪, 刘斌, 冯立, 赵文娟, 郝俊辉. 层状金属内嵌应力感知结构设计及超声波增材制造组织性能测试[J]. 兵工学报, 2023, 44(12): 3783-3792. |

| [3] | 辛大钧, 薛琨. 基于人工神经网络的非球形破片阻力系数预测模型[J]. 兵工学报, 2022, 43(5): 1083-1092. |

| [4] | 刘铁磊, 徐豫新, 王晓锋, 张鹏, 张健. 钨合金球形破片侵彻低碳钢的弹道极限速度计算模型[J]. 兵工学报, 2022, 43(4): 768-779. |

| [5] | 沈超, 周克栋, 陆野, 乔自平. 内膛损伤枪管对内弹道性能和弹头出膛状态的影响研究[J]. 兵工学报, 2019, 40(4): 718-727. |

| [6] | 金丹, 张江玉, 李江华. 316L不锈钢圆路径下的动态应变时效分析[J]. 兵工学报, 2018, 39(3): 584-589. |

| [7] | 梁泰鑫, 吕秉峰, 马忠亮, 肖忠良. 一种随行装药的燃烧性能[J]. 兵工学报, 2015, 36(9): 1660-1664. |

| [8] | 莫根林, 吴志林, 刘坤. 球形破片侵彻明胶的瞬时空腔模型[J]. 兵工学报, 2013, 34(10): 1324-1328. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4