主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (3): 963-974.doi: 10.12382/bgxb.2022.0884

刘梦真1,2, 黄广炎1,2,3, 张宏1,2,3,*( ), 周宏元4, 刘思宇5

), 周宏元4, 刘思宇5

收稿日期:2022-09-30

上线日期:2023-01-03

通讯作者:

基金资助:

LIU Mengzhen1,2, HUANG Guangyan1,2,3, ZHANG Hong1,2,3,*( ), ZHOU Hongyuan4, LIU Siyu5

), ZHOU Hongyuan4, LIU Siyu5

Received:2022-09-30

Online:2023-01-03

摘要:

防刺服能在恐怖袭击、医闹伤害、违法犯罪等事件中有效保护生命安全,然而在生产制造及穿着使用中易产生机械折痕。立足于防护材料折痕缺陷的快速检测需求,创新性地在图像识别方法中提出特征分段网络结构,实现了小样本驱动下防护材料折痕的快速、精准检测功能。通过引入注意力机制和深度可分离卷积模块,并赋予损失函数与优化器两种典型参数,全面提高了特征分段网络模型的检测精度与效率;提出几何信息标注算法,搭建防护材料缺陷可视化检测平台,实现了机械折痕自动精准定位与几何信息输出。模型训练结果表明,特征分段网络模型的准确率可达96.19%,折痕缺陷几何信息标注误差在2%以内,优异的可视化检测功能可拓展到大型工程化自动检测领域。研究工作为下一步构建含有折痕缺陷的防刺装备防护性能预测模型奠定了基础。

中图分类号:

刘梦真, 黄广炎, 张宏, 周宏元, 刘思宇. 小样本驱动特征分段网络的防护材料折痕检测[J]. 兵工学报, 2024, 45(3): 963-974.

LIU Mengzhen, HUANG Guangyan, ZHANG Hong, ZHOU Hongyuan, LIU Siyu. Protective Material Crease Detection with Small Sample-driven Feature Segmented Neural Network[J]. Acta Armamentarii, 2024, 45(3): 963-974.

| 硬件 | 主要参数 | 厂商 |

|---|---|---|

| 工业相机 | 分辨率4022×3036 | 杭州海康威视数字技术股份有限公司 |

| 镜头 | 焦距8mm | 杭州海康威视数字技术股份有限公司 |

| 工业光源 | 300mm×300mm | 杭州海康威视数字技术股份有限公司 |

| 光源控制器 | 2通道,24V光源 | 大康控股集团有限 公司 |

| 相机夹具 | 最大距离100mm | 定制 |

| 可拼接镀铬 精密管 | ϕ25×400mm | 定制 |

| 光源架 | 280mm×180mm | 定制 |

| 透明板 | 280mm×180mm | 定制 |

| 底板 | 300mm×300mm | 定制 |

表1 系统硬件参数

Table 1 System hardware parameters

| 硬件 | 主要参数 | 厂商 |

|---|---|---|

| 工业相机 | 分辨率4022×3036 | 杭州海康威视数字技术股份有限公司 |

| 镜头 | 焦距8mm | 杭州海康威视数字技术股份有限公司 |

| 工业光源 | 300mm×300mm | 杭州海康威视数字技术股份有限公司 |

| 光源控制器 | 2通道,24V光源 | 大康控股集团有限 公司 |

| 相机夹具 | 最大距离100mm | 定制 |

| 可拼接镀铬 精密管 | ϕ25×400mm | 定制 |

| 光源架 | 280mm×180mm | 定制 |

| 透明板 | 280mm×180mm | 定制 |

| 底板 | 300mm×300mm | 定制 |

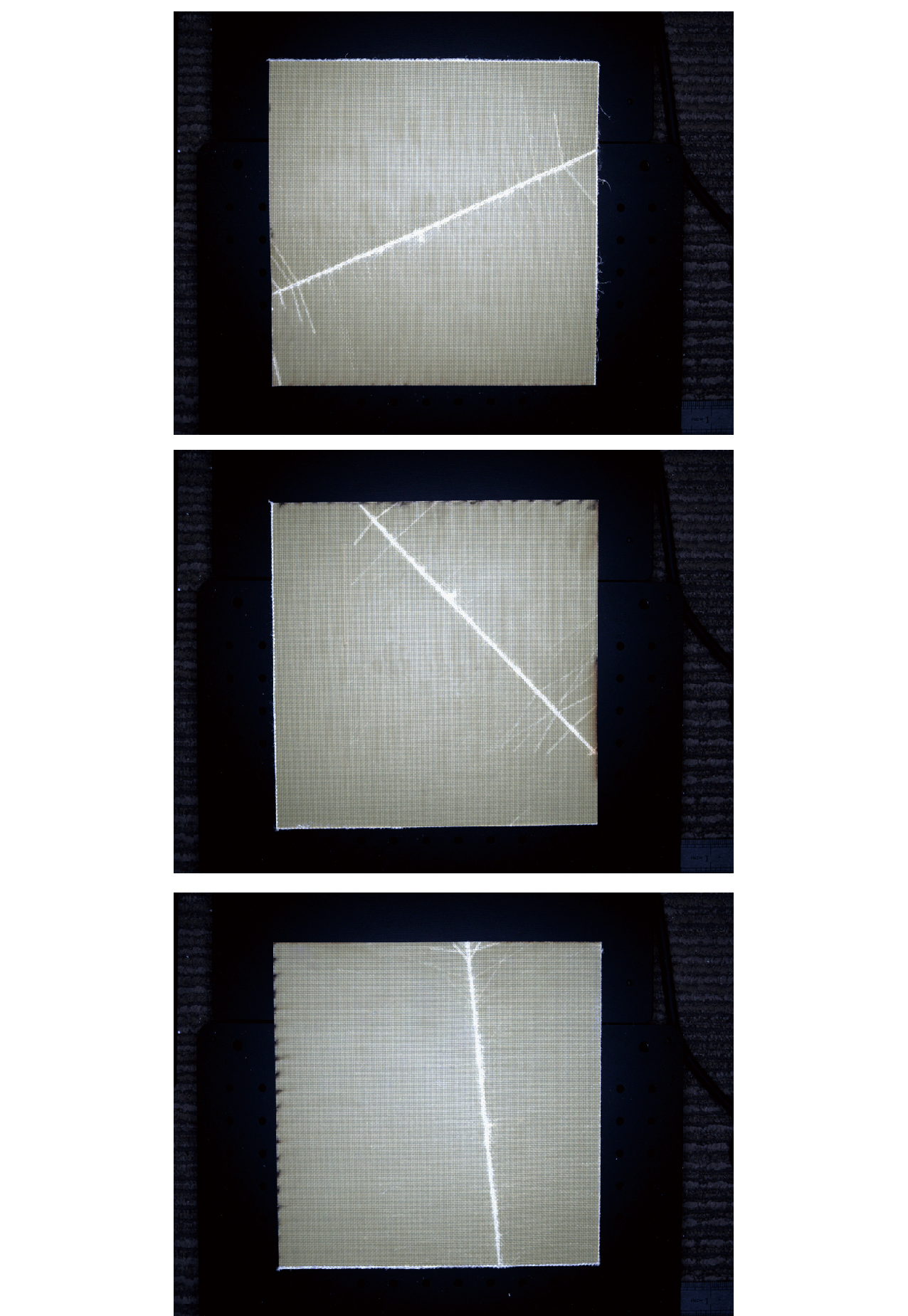

图4 产生左下至右上(上)、左上至右下(中)以及竖直(下)机械折痕的防护材料图像

Fig.4 Images of protective material that produce bottom-left to top-right (upper), top-left to bottom-right (middle), and vertical (below) mechanical creases

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 二维卷积层 | 3 | 32 | 5×5 | 1024×1024 | |

| 1 | 二维卷积层 | 32 | 32 | 5×5 | 1024×1024 |

| 池化层 | 32 | 32 | 2×2 | 512×512 | |

| 二维卷积层 | 32 | 64 | 5×5 | 512×512 | |

| 2 | 二维卷积层 | 64 | 64 | 5×5 | 512×512 |

| 二维卷积层 | 64 | 64 | 5×5 | 512×512 | |

| 池化层 | 64 | 64 | 2×2 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 3 | 二维卷积层 | 64 | 64 | 5×5 | 256×256 |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 池化层 | 64 | 64 | 2×2 | 128×128 | |

| 注意力层 | 二维卷积层 | 64 | 4 | 1×1 | 128×128 |

| 二维卷积层 | 4 | 64 | 1×1 | 128×128 | |

| 4 | 二维卷积层 | 64 | 1024 | 15×15 | 128×128 |

| 5 | 二维卷积层 | 1024 | 1 | 1×1 | 128×128 |

表2 分割网络结构主要参数

Table 2 Major parameters of segmented network structure

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 二维卷积层 | 3 | 32 | 5×5 | 1024×1024 | |

| 1 | 二维卷积层 | 32 | 32 | 5×5 | 1024×1024 |

| 池化层 | 32 | 32 | 2×2 | 512×512 | |

| 二维卷积层 | 32 | 64 | 5×5 | 512×512 | |

| 2 | 二维卷积层 | 64 | 64 | 5×5 | 512×512 |

| 二维卷积层 | 64 | 64 | 5×5 | 512×512 | |

| 池化层 | 64 | 64 | 2×2 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 3 | 二维卷积层 | 64 | 64 | 5×5 | 256×256 |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 池化层 | 64 | 64 | 2×2 | 128×128 | |

| 注意力层 | 二维卷积层 | 64 | 4 | 1×1 | 128×128 |

| 二维卷积层 | 4 | 64 | 1×1 | 128×128 | |

| 4 | 二维卷积层 | 64 | 1024 | 15×15 | 128×128 |

| 5 | 二维卷积层 | 1024 | 1 | 1×1 | 128×128 |

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 深度 可分离 卷积层 | 二维卷积层 | 1 025 | 1 025 | 5×5 | 128×128 |

| 二维卷积层 | 1 025 | 8 | 5×5 | 128×128 | |

| 池化层 | 8 | 8 | 2×2 | 64×64 | |

| 二维卷积层 | 8 | 8 | 5×5 | 64×64 | |

| 二维卷积层 | 8 | 16 | 5×5 | 64×64 | |

| 池化层 | 16 | 16 | 2×2 | 32×32 | |

| 二维卷积层 | 16 | 32 | 5×5 | 32×32 | |

| 1 | 线性层 | 66 | 1 | — | 1×1 |

表3 决策网络结构主要参数

Table 3 Major parameters of decision network structure

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 深度 可分离 卷积层 | 二维卷积层 | 1 025 | 1 025 | 5×5 | 128×128 |

| 二维卷积层 | 1 025 | 8 | 5×5 | 128×128 | |

| 池化层 | 8 | 8 | 2×2 | 64×64 | |

| 二维卷积层 | 8 | 8 | 5×5 | 64×64 | |

| 二维卷积层 | 8 | 16 | 5×5 | 64×64 | |

| 池化层 | 16 | 16 | 2×2 | 32×32 | |

| 二维卷积层 | 16 | 32 | 5×5 | 32×32 | |

| 1 | 线性层 | 66 | 1 | — | 1×1 |

| 网络 | 学习率 | 权重衰减系数 | 单次训练样本数 |

|---|---|---|---|

| 分割网络 | 0.00002 | 0.5 | 2 |

| 决策网络 | 0.002 | 0.5 | 2 |

表4 网络训练主要参数

Table 4 Major parameters of training neural network

| 网络 | 学习率 | 权重衰减系数 | 单次训练样本数 |

|---|---|---|---|

| 分割网络 | 0.00002 | 0.5 | 2 |

| 决策网络 | 0.002 | 0.5 | 2 |

| 模型 | 准确 率/% | 查准 率/% | 召回 率/% | F1 值 | 图像处理帧率/ (帧·s-1) |

|---|---|---|---|---|---|

| Models_Original | 67.62 | 92.86 | 55.71 | 69.64 | 5.96 |

| Models_Depthwise | 87.62 | 95.97 | 85.00 | 90.15 | 7.47 |

| Models_Depthwise_SE | 96.19 | 100.00 | 94.29 | 97.06 | 6.06 |

| YOLOv5s | 84.60 | 82.60 | 84.00 | 83.28 | 46.95 |

表5 模型效果的结果对比

Table 5 Comparison of the results of the models

| 模型 | 准确 率/% | 查准 率/% | 召回 率/% | F1 值 | 图像处理帧率/ (帧·s-1) |

|---|---|---|---|---|---|

| Models_Original | 67.62 | 92.86 | 55.71 | 69.64 | 5.96 |

| Models_Depthwise | 87.62 | 95.97 | 85.00 | 90.15 | 7.47 |

| Models_Depthwise_SE | 96.19 | 100.00 | 94.29 | 97.06 | 6.06 |

| YOLOv5s | 84.60 | 82.60 | 84.00 | 83.28 | 46.95 |

| [1] |

邱日祥, 韩启龙. 防刺服的现状与发展[J]. 装备发展, 2020(5):77-81.

|

|

|

|

| [2] |

冯浩, 汪泽幸, 何斌, 等. 防刺服的研究与发展现状[J]. 产业用纺织品, 2021, 39(2):8-13,17.

|

|

|

|

| [3] |

doi: 10.1007/s10845-014-0876-9 URL |

| [4] |

doi: 10.1109/ACCESS.2018.2868059 URL |

| [5] |

doi: 10.3390/app12136633 URL |

| [6] |

doi: 10.1007/s10845-008-0140-2 URL |

| [7] |

廖达海, 殷明帅, 罗宏斌, 等. 基于耦合去噪算法的航空发动机中Si3N4圆柱滚子表面缺陷的检测方法[J]. 兵工学报, 2022, 43(1):191-198.

|

|

|

|

| [8] |

张良安, 陈洋, 谢胜龙, 等. 基于机器视觉与深度学习的飞机防护栅裂纹检测系统[J]. 兵工学报, 2023, 44(2):507-516.

|

|

|

|

| [9] |

|

| [10] |

|

| [11] |

doi: 10.1007/s00170-020-05887-6 |

| [12] |

doi: 10.1007/s10845-018-1412-0 |

| [13] |

doi: 10.1080/17452759.2020.1832695 URL |

| [14] |

doi: 10.1126/science.1127647 pmid: 16873662 |

| [15] |

doi: 10.1145/3065386 URL |

| [16] |

|

| [17] |

张博尧, 冷雁冰. 基于YOLOv4网络模型的金属表面划痕检测[J]. 兵工学报, 2022, 43(增刊1):214-221.

|

|

doi: 10.12382/bgxb.2022.A011 |

|

| [18] |

|

| [19] |

doi: 10.1016/j.cirp.2016.04.072 URL |

| [20] |

|

| [21] |

doi: 10.1007/s11263-007-0090-8 URL |

| [22] |

doi: 10.1109/JPROC.2010.2050290 URL |

| [23] |

|

| [24] |

|

| [25] |

pmid: 16173190 |

| [26] |

|

| [27] |

doi: 10.1002/(ISSN)1099-131X URL |

| [28] |

|

| [29] |

|

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4