主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (1): 58-68.doi: 10.12382/bgxb.2022.0696

黄炫宁1, 李伟兵1,*( ), 李文彬1, 尹贵祥1, 郭腾飞2

), 李文彬1, 尹贵祥1, 郭腾飞2

收稿日期:2022-08-03

上线日期:2024-01-30

通讯作者:

基金资助:

HUANG Xuanning1, LI Weibing1,*( ), LI Wenbin1, YIN Guixiang1, GUO Tengfei2

), LI Wenbin1, YIN Guixiang1, GUO Tengfei2

Received:2022-08-03

Online:2024-01-30

摘要:

为研究靶板材料性能对爆炸成型弹丸(Explosively Formed Projectile,EFP)侵彻靶后破片特性的影响,开展EFP侵彻不同材料靶板(Q235钢、45号钢、装甲钢、2A12铝)后效破片特性试验,采用X光摄影方法观测靶后破片云形态及膨胀尺寸,通过布置多层纤维板获得破片散布特性,并对靶后破片进行回收。研究结果表明:在靶板密度一定的情况下,靶板强度主要影响破片云轴向膨胀能力,对径向膨胀能力影响很小;靶后破片环形毁伤区的飞散角位于20°~25°范围内差别不大,但是靶板背面出口崩落会造成靶后破片飞散角出现极大值,随着钢靶强度的增大,靶后破片径向散布增强,破片总数减小,但是大质量段钢破片数量增多;不同强度钢靶产生的钢破片平均尺寸满足Kipp等提出的基于材料流动应力的碎片尺寸模型。

中图分类号:

黄炫宁, 李伟兵, 李文彬, 尹贵祥, 郭腾飞. 爆炸成型弹丸侵彻不同材料靶板后效破片特性试验研究[J]. 兵工学报, 2024, 45(1): 58-68.

HUANG Xuanning, LI Weibing, LI Wenbin, YIN Guixiang, GUO Tengfei. Experimental Research on the Characteristics of Behind-armor Debris from Explosively Formed Projectile Penetrating Targets of Different Materials[J]. Acta Armamentarii, 2024, 45(1): 58-68.

| 靶板 材料 | 靶板破片 | EFP破片 | ||||

|---|---|---|---|---|---|---|

| c | λ | R2 | c | λ | R2 | |

| Q235钢 | 1.56 | 1.00 | 0.984 | 1.02 | 0.93 | 0.977 |

| RHA | 5.42 | 1.28 | 0.977 | 1.38 | 1.04 | 0.987 |

| 45号钢 | 1.44 | 0.80 | 0.984 | 0.78 | 0.89 | 0.981 |

| 2A12铝 | 0.19 | 1.08 | 0.918 | 0.27 | 0.72 | 0.896 |

表1 靶后破片质量分布拟合参数

Table 1 Fitting parameters of fragment mass distribution

| 靶板 材料 | 靶板破片 | EFP破片 | ||||

|---|---|---|---|---|---|---|

| c | λ | R2 | c | λ | R2 | |

| Q235钢 | 1.56 | 1.00 | 0.984 | 1.02 | 0.93 | 0.977 |

| RHA | 5.42 | 1.28 | 0.977 | 1.38 | 1.04 | 0.987 |

| 45号钢 | 1.44 | 0.80 | 0.984 | 0.78 | 0.89 | 0.981 |

| 2A12铝 | 0.19 | 1.08 | 0.918 | 0.27 | 0.72 | 0.896 |

| 钢靶材料 | A1 | t1 | y0 | R2 |

|---|---|---|---|---|

| Q235钢 | -16.87 | -0.51 | 1.86 | 0.985 |

| 45号钢 | -6.55 | -0.73 | 1.85 | 0.982 |

| RHA | -9.84 | -0.52 | 1.63 | 0.995 |

表2 破片累计数量分布拟合结果

Table 2 Fitting results of cumulative number distribution of fragments

| 钢靶材料 | A1 | t1 | y0 | R2 |

|---|---|---|---|---|

| Q235钢 | -16.87 | -0.51 | 1.86 | 0.985 |

| 45号钢 | -6.55 | -0.73 | 1.85 | 0.982 |

| RHA | -9.84 | -0.52 | 1.63 | 0.995 |

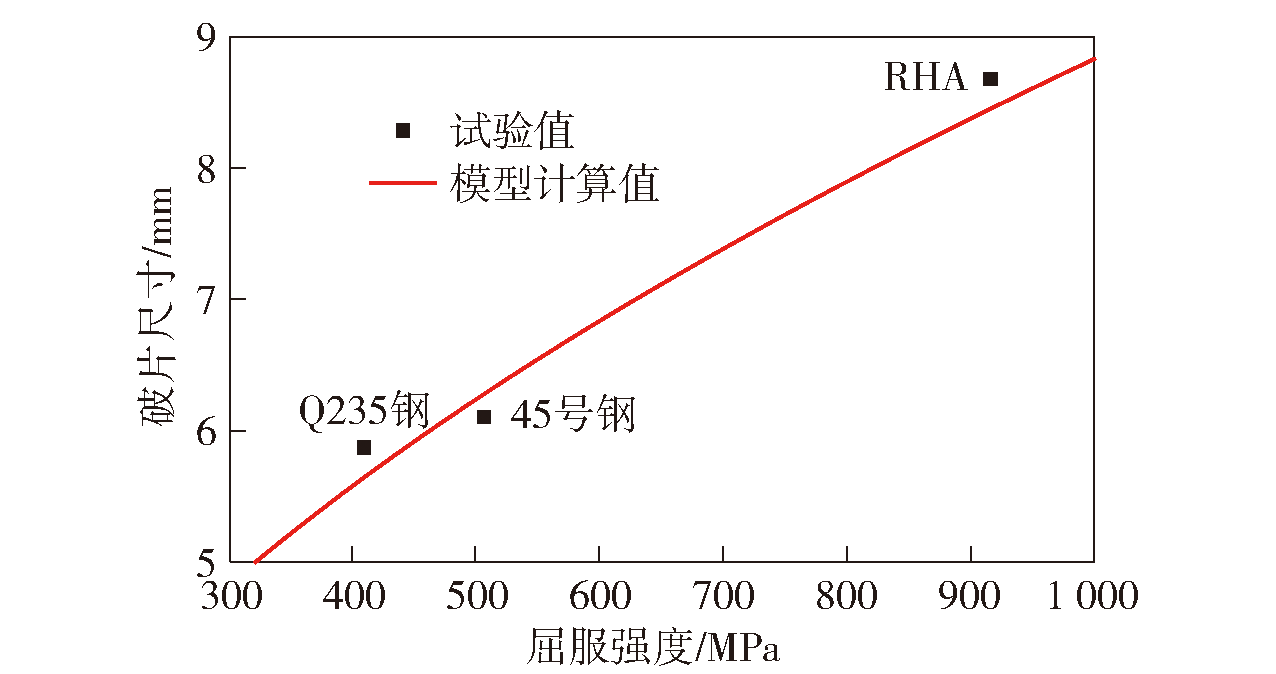

图15 不同钢靶产生的破片特征尺寸的试验与模型计算值

Fig.15 Experimental and model calculation values of the characteristic size of fragments produced by different steel targets

| 靶板材料 | 试验值/mm | 模型计算值/mm | 相对误差/% |

|---|---|---|---|

| Q235钢 | 5.87 | 5.65 | 3.68 |

| 45号钢 | 6.10 | 6.29 | 3.03 |

| RHA | 8.68 | 8.45 | 2.60 |

表3 钢破片特征尺寸的模型与试验结果对比

Table 3 Comparison between model and experimental results of characteristic sizes of steel fragments

| 靶板材料 | 试验值/mm | 模型计算值/mm | 相对误差/% |

|---|---|---|---|

| Q235钢 | 5.87 | 5.65 | 3.68 |

| 45号钢 | 6.10 | 6.29 | 3.03 |

| RHA | 8.68 | 8.45 | 2.60 |

| [1] |

|

| [2] |

doi: 10.1016/j.ijimpeng.2006.09.007 URL |

| [3] |

doi: 10.1016/S0734-743X(01)00071-9 URL |

| [4] |

|

| [5] |

doi: 10.1016/j.dt.2019.05.016 |

| [6] |

王昕, 蒋建伟, 王树有, 等. 爆炸成型弹丸侵彻钢靶的后效破片云实验研究[J]. 兵工学报, 2018, 39(7): 1284-1290.

doi: 10.3969/j.issn.1000-1093.2018.07.005 |

|

doi: 10.3969/j.issn.1000-1093.2018.07.005 |

|

| [7] |

doi: 10.1016/j.dt.2018.10.006 |

| [8] |

邢柏阳, 侯云辉, 李泰华, 等. 爆炸成型弹丸垂直侵彻装甲钢靶后破片动能分析[J]. 兵工学报, 2019, 40(10):2014-2021.

doi: 10.3969/j.issn.1000-1093.2019.10.006 |

|

doi: 10.3969/j.issn.1000-1093.2019.10.006 |

|

| [9] |

邢柏阳, 赵建霞, 陈亮, 等. 爆炸成型弹丸垂直穿透钢板靶后破片飞散特性[J]. 北京理工大学学报, 2022, 42(10):1026-1033.

|

|

|

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

doi: 10.1016/S0734-743X(97)87507-0 URL |

| [14] |

doi: 10.1016/0734-743X(95)99887-W URL |

| [15] |

doi: 10.1016/j.ijimpeng.2021.104034 URL |

| [16] |

doi: 10.1016/j.ijimpeng.2019.103387 URL |

| [17] |

黄正祥, 祖旭东. 终点效应[M]. 北京: 科学出版社, 2014.

|

|

|

|

| [18] |

doi: 10.1016/j.ijimpeng.2003.09.009 URL |

| [19] |

doi: 10.1016/0734-743X(93)90040-E URL |

| [20] |

doi: 10.1016/j.ijimpeng.2006.09.067 URL |

| [21] |

黄炫宁, 李伟兵, 郭腾飞, 等. EFP垂直侵彻靶板后效破片云形状描述[J]. 含能材料, 2020, 28(11):1068-1075.

|

|

|

|

| [22] |

doi: 10.1016/j.ijimpeng.2020.103721 URL |

| [23] |

|

| [24] |

doi: 10.1016/j.ijimpeng.2003.10.029 URL |

| [25] |

段占强, 程国强, 李守新, 等. 高速冲击下钢板的微观组织及绝热剪切带[J]. 金属学报, 2003, 39(5):486-491.

|

|

|

|

| [26] |

李晓源, 时捷, 董瀚. 不同强度的40CrNi2Mo钢抗弹性能研究[J]. 兵器材料科学与工程, 2008, 31(1):14-18.

|

|

|

|

| [27] |

张先锋, 陈惠武, 赵有守. EFP对有限厚靶板侵彻过程及后效研究[J]. 爆炸与冲击, 2006, 26(4):323-327.

|

|

|

|

| [28] |

doi: 10.1016/S0734-743X(99)00028-7 URL |

| [29] |

doi: 10.1063/1.329934 URL |

| [30] |

doi: 10.1016/j.ijimpeng.2003.09.026 URL |

| [31] |

陈刚, 陈忠富, 陶俊林, 等. 45钢动态塑性本构参量与验证[J]. 爆炸与冲击, 2005, 25(5):69-74.

|

|

|

|

| [32] |

陈刚, 陈小伟, 陈忠富, 等. A3钢钝头弹撞击45钢板破坏模式的数值分析[J]. 爆炸与冲击, 2007, 27(5):390-397.

|

|

|

|

| [33] |

doi: 10.1016/S0734-743X(02)00009-X URL |

| [1] | 高鹏, 王芳, 汪聪, 牛文煜. 偏心药型罩在D型装药中的设计及成型性能研究[J]. 兵工学报, 2024, 45(3): 720-730. |

| [2] | 郑元枫, 王仕鹏, 李培亮, 张勇, 葛超. 活性/金属串联爆炸成型弹丸侵爆耦合毁伤行为[J]. 兵工学报, 2023, 44(8): 2273-2282. |

| [3] | 冯炜, 崔东华, 刘海晓, 周末, 赵江, 李恒, 胡志鹏. 反无人艇群弹药战斗部参数对效能影响分析[J]. 兵工学报, 2022, 43(S2): 26-31. |

| [4] | 付恒, 蒋建伟, 王树有, 门建兵, 李梅. 爆炸成型弹丸药型罩用高密度合金选取准则[J]. 兵工学报, 2022, 43(9): 2330-2338. |

| [5] | 任思远, 张庆明, 张晓伟, 田志敏. 环形射流和中心爆炸成型弹丸组合战斗部对混凝土墙的破孔特性[J]. 兵工学报, 2021, 42(8): 1569-1579. |

| [6] | 门建兵, 聂源, 蒋建伟, 王树有, 冯高鹏. 反爆炸反应装甲串联爆炸成型弹丸匹配设计方法[J]. 兵工学报, 2020, 41(12): 2369-2378. |

| [7] | 邢柏阳, 侯云辉, 李泰华, 张东江, 刘荣忠, 郭锐. 爆炸成型弹丸垂直侵彻装甲钢靶后破片动能分析[J]. 兵工学报, 2019, 40(10): 2014-2021. |

| [8] | 聂源, 蒋建伟, 王树有, 刘瀚. 爆炸反应装甲对爆炸成型弹丸侵彻效应影响的实验研究[J]. 兵工学报, 2018, 39(8): 1576-1581. |

| [9] | 杨云川, 朱建军, 郑宇, 李文彬, 王晓鸣, 乔相信, 李瑞. 战斗部壳体爆炸破片体/线分形维数研究[J]. 兵工学报, 2018, 39(8): 1499-1506. |

| [10] | 钟巍, 田宙, 寿列枫, 李伟昌, 何增, 浦锡锋, 王仲琦. 基于量纲分析的爆炸冲击波作用后钢化玻璃碎片质量分布规律研究[J]. 兵工学报, 2018, 39(7): 1323-1332. |

| [11] | 王昕, 蒋建伟, 王树有, 李梅. 爆炸成型弹丸侵彻钢靶的后效破片云实验研究[J]. 兵工学报, 2018, 39(7): 1284-1290. |

| [12] | 王钰, 于纪言, 王晓鸣, 冯斌. 修正组件结构参数对旋转稳定弹道修正弹稳定性的影响研究[J]. 兵工学报, 2018, 39(10): 1910-1918. |

| [13] | 王哲, 蒋建伟, 王树有, 任芮池. 双层药型罩形成的串联爆炸成型弹丸速度计算模型[J]. 兵工学报, 2017, 38(7): 1301-1306. |

| [14] | 丁力, 蒋建伟, 门建兵, 王树有. 爆炸成型弹丸成型过程中的断裂数值模拟及机理分析[J]. 兵工学报, 2017, 38(3): 417-423. |

| [15] | 朱建军, 李伟兵, 李文彬, 王晓鸣, 郑宇, 卢海涛, 袁书强. 高应变率下金属柱壳动态变形及形成破片特性研究[J]. 兵工学报, 2017, 38(10): 1933-1941. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4