Responsible Institution: China Association for Science and Technology

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Acta Armamentarii ›› 2025, Vol. 46 ›› Issue (6): 240533-.doi: 10.12382/bgxb.2024.0533

Previous Articles Next Articles

WANG Zhanxuan1, LI Xintian1, XU Lizhi1,*( ), DU Zhonghua1,2,**(

), DU Zhonghua1,2,**( )

)

Received:2024-07-02

Online:2025-06-28

Contact:

XU Lizhi, DU Zhonghua

CLC Number:

WANG Zhanxuan, LI Xintian, XU Lizhi, DU Zhonghua. Comparative Study on Predictive Models for Radial Velocities of Fragments after PELE Impacting on Target Plates[J]. Acta Armamentarii, 2025, 46(6): 240533-.

Add to citation manager EndNote|Ris|BibTeX

| 材料 | ρ/(g·cm-3) | c/(km·s-1) | S1 | Grüneisen 常数 | E/GPa | 拉伸主 应变 | 拉伸主应 力/GPa | 断裂软化 算法 | 随机失效 算法 | 侵蚀应变 |

|---|---|---|---|---|---|---|---|---|---|---|

| 钨合金 | 18.00 | 4.029 | 1237 | 0 | 360.0 | 0.035 | 2.8 | 是 | 是 | 0.6 |

| A-G3铝 | 2.650 | 5.176 | 1.350 | 1.97 | 63.90 | 否 | 否 | 0.8 | ||

| PE | 9.200 | 2.187 | 1.481 | 1.64 | 1.060 | 否 | 否 | 0.8 | ||

| 尼龙[ | 1.130 | 2.290 | 1.630 | 0.87 | 23.00 | 否 | 否 | 0.8 | ||

| XC48钢 | 7.823 | 4.797 | 1.490 | 0.00 | 201.0 | 否 | 否 | |||

| A-U4G铝 | 2.800 | 5.106 | 1.350 | 2.00 | 74.00 | 否 | 否 |

Table 1 Material parameters

| 材料 | ρ/(g·cm-3) | c/(km·s-1) | S1 | Grüneisen 常数 | E/GPa | 拉伸主 应变 | 拉伸主应 力/GPa | 断裂软化 算法 | 随机失效 算法 | 侵蚀应变 |

|---|---|---|---|---|---|---|---|---|---|---|

| 钨合金 | 18.00 | 4.029 | 1237 | 0 | 360.0 | 0.035 | 2.8 | 是 | 是 | 0.6 |

| A-G3铝 | 2.650 | 5.176 | 1.350 | 1.97 | 63.90 | 否 | 否 | 0.8 | ||

| PE | 9.200 | 2.187 | 1.481 | 1.64 | 1.060 | 否 | 否 | 0.8 | ||

| 尼龙[ | 1.130 | 2.290 | 1.630 | 0.87 | 23.00 | 否 | 否 | 0.8 | ||

| XC48钢 | 7.823 | 4.797 | 1.490 | 0.00 | 201.0 | 否 | 否 | |||

| A-U4G铝 | 2.800 | 5.106 | 1.350 | 2.00 | 74.00 | 否 | 否 |

| 编号 | 弹芯材料 | 靶板材料 | 靶板厚 度/mm | 冲击速度/ (m·s-1) |

|---|---|---|---|---|

| 1 | A-G3铝 | A-U4G铝 | 3 | 300~2 700 |

| 2 | A-G3铝 | XC 48钢 | ||

| 3 | PE | A-U4G铝 | ||

| 4 | PE | XC 48钢 | ||

| 5 | 尼龙 | A-U4G铝 | ||

| 6 | 尼龙 | XC 48钢 |

Table 2 Numerical model parameters

| 编号 | 弹芯材料 | 靶板材料 | 靶板厚 度/mm | 冲击速度/ (m·s-1) |

|---|---|---|---|---|

| 1 | A-G3铝 | A-U4G铝 | 3 | 300~2 700 |

| 2 | A-G3铝 | XC 48钢 | ||

| 3 | PE | A-U4G铝 | ||

| 4 | PE | XC 48钢 | ||

| 5 | 尼龙 | A-U4G铝 | ||

| 6 | 尼龙 | XC 48钢 |

| 靶板材料 | 碰撞压力仿真结果 | 最终碰撞压力对比 |

|---|---|---|

| A-U4G铝 | | |

| XC 48钢 | | |

Table 3 Impact pressure curve at different velocities(aluminium filling)

| 靶板材料 | 碰撞压力仿真结果 | 最终碰撞压力对比 |

|---|---|---|

| A-U4G铝 | | |

| XC 48钢 | | |

| 弹芯材料 | 靶板材料 | 碰撞压力仿真结果 | 最终碰撞压力对比 |

|---|---|---|---|

| PE | A-U4G铝 | | |

| XC 48钢 | | | |

| 尼龙 | A-U4G铝 | | |

| XC 48钢 | | |

Table 4 Imapct pressure curves at different velocities(PE and nylon filling)

| 弹芯材料 | 靶板材料 | 碰撞压力仿真结果 | 最终碰撞压力对比 |

|---|---|---|---|

| PE | A-U4G铝 | | |

| XC 48钢 | | | |

| 尼龙 | A-U4G铝 | | |

| XC 48钢 | | |

| 靶板材料 | 冲击速度/(m·s-1) | |

|---|---|---|

| 300 | 2700 | |

| A-U4G铝 | 0.79 | 12.37 |

| XC 48钢 | 0.87 | 15.84 |

Table 5 Pressure of PELE impacting on target plate with nylon filling GPa

| 靶板材料 | 冲击速度/(m·s-1) | |

|---|---|---|

| 300 | 2700 | |

| A-U4G铝 | 0.79 | 12.37 |

| XC 48钢 | 0.87 | 15.84 |

| 模型 | 碰撞压力 | 径向压力 | 破片停止加速 |

|---|---|---|---|

| 3 | pb=ρaca(ub-ua)+ρas | σr=σx,f | εr,lim(t)= |

| 4 | pb=ρaca(ub-ua)+ρas | σr=σx,f | εmax=0.035 |

Table 6 Two calculation models

| 模型 | 碰撞压力 | 径向压力 | 破片停止加速 |

|---|---|---|---|

| 3 | pb=ρaca(ub-ua)+ρas | σr=σx,f | εr,lim(t)= |

| 4 | pb=ρaca(ub-ua)+ρas | σr=σx,f | εmax=0.035 |

| 编号 | 弹芯 | 靶板 | 冲击 速度/ (m·s-1) | |||

|---|---|---|---|---|---|---|

| 密度/ (g·cm-3) | 泊松 比 | 弹性模 量/GPa | 密度/ (g·cm-3) | 厚度/ mm | ||

| 7 | 1.09 | 0.45 | 10.7 | 7.85 | 2 | 632 |

| 8 | 1.09 | 0.45 | 10.7 | 711 | ||

| 9 | 1.09 | 0.45 | 10.7 | 811 | ||

| 10 | 1.09 | 0.45 | 10.7 | 890 | ||

| 11 | 0.96 | 0.40 | 28.3 | 775 | ||

| 12 | 1.40 | 0.33 | 68.1 | 802 | ||

Table 7 Experimental condition parameters in Ref.[23]

| 编号 | 弹芯 | 靶板 | 冲击 速度/ (m·s-1) | |||

|---|---|---|---|---|---|---|

| 密度/ (g·cm-3) | 泊松 比 | 弹性模 量/GPa | 密度/ (g·cm-3) | 厚度/ mm | ||

| 7 | 1.09 | 0.45 | 10.7 | 7.85 | 2 | 632 |

| 8 | 1.09 | 0.45 | 10.7 | 711 | ||

| 9 | 1.09 | 0.45 | 10.7 | 811 | ||

| 10 | 1.09 | 0.45 | 10.7 | 890 | ||

| 11 | 0.96 | 0.40 | 28.3 | 775 | ||

| 12 | 1.40 | 0.33 | 68.1 | 802 | ||

| 编号 | 弹芯 | 靶板 | 冲击 速度/ (m·s-1) | ||||

|---|---|---|---|---|---|---|---|

| 材料 | 密度/ (g·cm-3) | 泊松 比 | 密度/ (g·cm-3) | 厚度/ mm | |||

| 13 | 6061铝 | 2.70 | 0.33 | 2.800 | 3 | 798 | |

| 14 | 806 | ||||||

| 15 | 聚四氟 乙烯 | 2.15 | 0.41 | 802 | |||

| 16 | 809 | ||||||

Table 8 Experimental condition parameters in Ref.[21]

| 编号 | 弹芯 | 靶板 | 冲击 速度/ (m·s-1) | ||||

|---|---|---|---|---|---|---|---|

| 材料 | 密度/ (g·cm-3) | 泊松 比 | 密度/ (g·cm-3) | 厚度/ mm | |||

| 13 | 6061铝 | 2.70 | 0.33 | 2.800 | 3 | 798 | |

| 14 | 806 | ||||||

| 15 | 聚四氟 乙烯 | 2.15 | 0.41 | 802 | |||

| 16 | 809 | ||||||

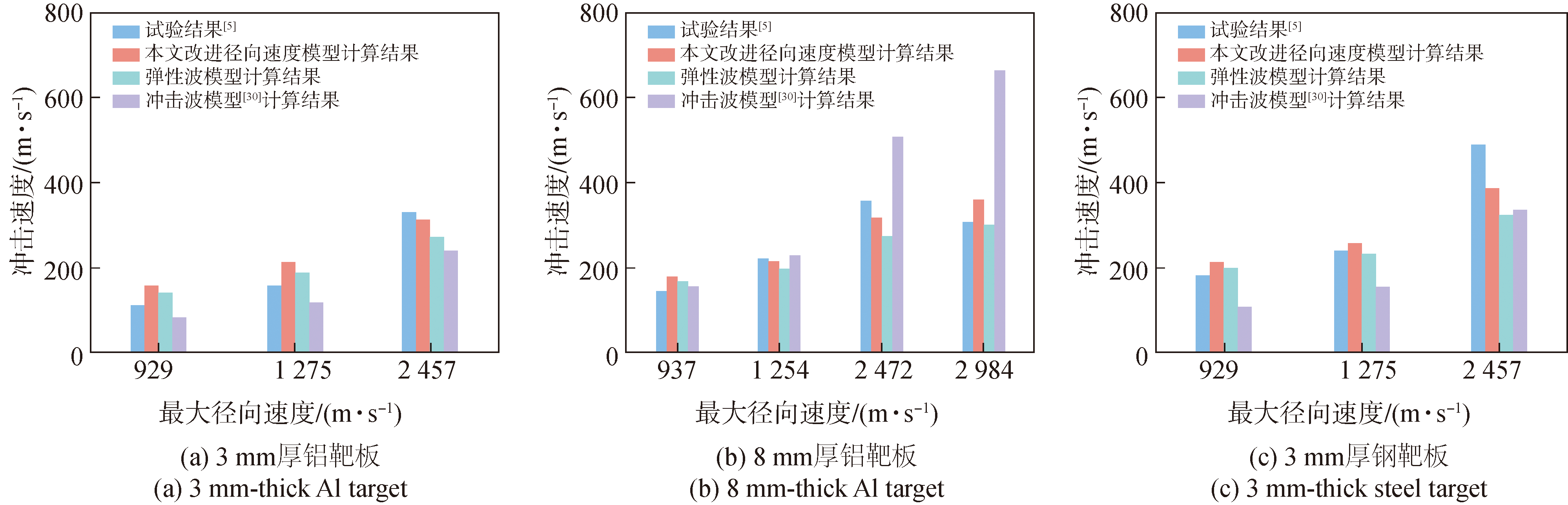

Fig.13 Comparison of calculated results of improved radial velocity model,impact model,and elastic wave model, as well as experimental results[5]( A-U4G Al filling)

Fig.14 Comparison of calculated results of improved radial velocity model,impact model, and elastic wave model,as well as experimental results[5] (PE filling)

| [1] |

|

| [2] |

|

| [3] |

朱建生, 范智, 杜忠华. 外壳材料对PELE作用效果的影响[J]. 兵器材料科学与工程, 2010, 33(6):14-16.

|

|

|

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

朱建生, 赵国志, 杜忠华. 装填材料对PELE效应的影响[J]. 弹道学报, 2007, 19(2):62-65.

|

|

|

|

| [8] |

|

| [9] |

|

| [10] |

张甲浩, 王海福, 葛超, 等. 活性PELE侵彻钢筋混凝土靶扩孔增强行为[J]. 兵工学报, 2025, 46 (3):240307.

|

|

|

|

| [11] |

张洪成, 尹建平, 王志军. 着靶角对PELE横向效应的影响[J]. 兵器材料科学与工程, 2012, 35(4):46-49.

|

|

|

|

| [12] |

刘宇珩, 霸书红, 杜忠华, 等. 着靶角度对PELE侵彻钢筋混凝土扩孔效应的影响研究[J]. 弹道学报, 2022, 34(4):15-22.

|

|

|

|

| [13] |

|

| [14] |

姬鹏远. 侵彻膨胀弹终点效应数值模拟研究[D]. 北京: 北京理工大学, 2007.

|

|

|

|

| [15] |

凃胜元, 沈晓军, 王军波, 等. 着速和靶厚对钢弹体PELE侵彻后效影响的实验研究[J]. 弹箭与制导学报, 2010, 30(3):69-71.

|

|

|

|

| [16] |

朱建生, 赵国志, 杜忠华, 等. 小口径PELE作用薄靶板影响因素的实验研究[J]. 实验力学, 2007, 22(5):505-510.

|

|

|

|

| [17] |

朱建生, 赵国志, 杜忠华, 等. 靶板厚度对横向效应增强型侵彻体作用效果的影响[J]. 南京理工大学学报(自然科学版), 2009, 33(4):474-479.

|

|

|

|

| [18] |

|

| [19] |

|

| [20] |

|

| [21] |

|

| [22] |

范少博, 陈智刚, 郭光全, 等. 装填材料对PELE侵彻混凝土效能影响研究[J]. 兵器材料科学与工程, 2012, 35(5):47-50.

|

|

|

|

| [23] |

|

| [24] |

|

| [25] |

|

| [26] |

张甲浩, 郭萌萌, 周晟, 等. 活性横向增强弹靶后横向效应实验与数值模拟[J]. 兵工学报, 2024, 45(7):2270-2281.

|

|

|

|

| [27] |

|

| [28] |

杜忠华, 宋丽丽. 横向效应增强型侵彻体撞击金属薄板理论模型[J]. 南京理工大学学报(自然科学版), 2011, 35(6):822-826.

|

|

|

|

| [29] |

|

| [30] |

|

| [31] |

|

| [32] |

|

| [33] |

|

| [34] |

王礼立. 应力波基础[M]. 北京: 国防工业出版社, 1985.

|

|

|

|

| [35] |

王仲仁, 苑世剑. 弹性与塑性力学基础[M]. 哈尔滨: 哈尔滨工业大学出版社, 1997.

|

|

|

|

| [36] |

|

| [1] | ZHANG Jiahao, WANG Haifu, GE Chao, ZHOU Sheng, YU Qingbo. Enhanced Opening Behavior of Reactive PELE Penetrating into Reinforced Concrete Target [J]. Acta Armamentarii, 2025, 46(3): 240307-. |

| [2] | WANG Yajun, YU Rui, LI Weibing, LI Wenbin. Research on the Penetration Characteristics of Rod-shaped EFP and Its Influencing Factors [J]. Acta Armamentarii, 2024, 45(S1): 174-182. |

| [3] | GUO Mengmeng, WANG Haifu, ZHANG Jiahao, ZHOU Sheng, YU Qingbo. Simulation Research on Damage Effect of PELE Penetrating Reinforced Concrete [J]. Acta Armamentarii, 2024, 45(S1): 89-96. |

| [4] | ZHANG Jiahao, GUO Mengmeng, ZHOU Sheng, YU Qingbo. Experimental and Numerical Research on Behind-plate Enhanced Lateral Effect of Reactive PELE [J]. Acta Armamentarii, 2024, 45(7): 2270-2281. |

| [5] | WANG Yili, LI Changsheng, WANG Xin, ZHANG He, WANG Xiaofeng. A Layer Counting Method for Penetration Fuze Based on Magnetic Anomaly Detection [J]. Acta Armamentarii, 2024, 45(3): 695-704. |

| [6] | FENG Wei, CUI Donghua, LIU Haixiao, ZHOU Mo, LI Heng, HU Zhipeng. Influence of Warhead Parameters of Munitions Against USV Group on Combat Effectiveness [J]. Acta Armamentarii, 2022, 43(S2): 26-31. |

| [7] | DAI Xianghui, DUAN Jian, SHEN Zikai, WANG Kehui, LI Mingrui, LI Pengjie, ZHENG Yafeng, ZHOU Gang. Experiment of Slow Cook-off Response Characteristics of Penetrator [J]. Acta Armamentarii, 2020, 41(2): 291-297. |

| [8] | XING Boyang, HOU Yunhui, LI Taihua, ZHANG Dongjiang, LIU Rongzhong, GUO Rui. Analysis of Kinetic Energy of Behind-armor Debris Generated during the Normal Penetration of EFP into Armor Steel [J]. Acta Armamentarii, 2019, 40(10): 2014-2021. |

| [9] | LI Peng, YUAN Bao-hui, SUN Xing-yun, LI Gang, LI Ji-zhen. Experimental Research on Eccentric Initiation MEFP Warhead [J]. Acta Armamentarii, 2017, 38(3): 447-453. |

| [10] | LUO Rong-mei, HUANG De-wu, YANG Ming-chuan, HUANG Hai, LI Fu-ying. Research on Melted and Rapidly Solidified Layer on the Surface of Crater Penetrated by Long Tungsten Rod [J]. Acta Armamentarii, 2015, 36(7): 1167-1175. |

| [11] | JIN Xue-ke, YU Qing-bo, ZHENG Yuan-feng, WANG Hai-fu. Damage Effects of High Velocity Penetrator on Chemical Submunition Payloads [J]. Acta Armamentarii, 2015, 36(3): 437-442. |

| [12] | CHEN Cheng, YUAN Xu-long, LIU Chuan-long. Experimental Investigation on the Supercavitation models Penetrating into Solid Medium and the Influence Factors [J]. Acta Armamentarii, 2015, 36(2): 299-304. |

| [13] | ZHAO Chang-xiao, LONG Yuan, JI Chong, Xu Dao-feng, GAO Fu-yin, LU Liang. Numerical Simulation and Experimental Research on Integral Multiple Explosively Formed Projectile Warhead [J]. Acta Armamentarii, 2013, 34(11): 1392-1397. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||