Responsible Institution: China Association for Science and Technology

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Acta Armamentarii ›› 2024, Vol. 45 ›› Issue (3): 963-974.doi: 10.12382/bgxb.2022.0884

Previous Articles Next Articles

LIU Mengzhen1,2, HUANG Guangyan1,2,3, ZHANG Hong1,2,3,*( ), ZHOU Hongyuan4, LIU Siyu5

), ZHOU Hongyuan4, LIU Siyu5

Received:2022-09-30

Online:2023-01-03

Contact:

ZHANG Hong

CLC Number:

LIU Mengzhen, HUANG Guangyan, ZHANG Hong, ZHOU Hongyuan, LIU Siyu. Protective Material Crease Detection with Small Sample-driven Feature Segmented Neural Network[J]. Acta Armamentarii, 2024, 45(3): 963-974.

Add to citation manager EndNote|Ris|BibTeX

| 硬件 | 主要参数 | 厂商 |

|---|---|---|

| 工业相机 | 分辨率4022×3036 | 杭州海康威视数字技术股份有限公司 |

| 镜头 | 焦距8mm | 杭州海康威视数字技术股份有限公司 |

| 工业光源 | 300mm×300mm | 杭州海康威视数字技术股份有限公司 |

| 光源控制器 | 2通道,24V光源 | 大康控股集团有限 公司 |

| 相机夹具 | 最大距离100mm | 定制 |

| 可拼接镀铬 精密管 | ϕ25×400mm | 定制 |

| 光源架 | 280mm×180mm | 定制 |

| 透明板 | 280mm×180mm | 定制 |

| 底板 | 300mm×300mm | 定制 |

Table 1 System hardware parameters

| 硬件 | 主要参数 | 厂商 |

|---|---|---|

| 工业相机 | 分辨率4022×3036 | 杭州海康威视数字技术股份有限公司 |

| 镜头 | 焦距8mm | 杭州海康威视数字技术股份有限公司 |

| 工业光源 | 300mm×300mm | 杭州海康威视数字技术股份有限公司 |

| 光源控制器 | 2通道,24V光源 | 大康控股集团有限 公司 |

| 相机夹具 | 最大距离100mm | 定制 |

| 可拼接镀铬 精密管 | ϕ25×400mm | 定制 |

| 光源架 | 280mm×180mm | 定制 |

| 透明板 | 280mm×180mm | 定制 |

| 底板 | 300mm×300mm | 定制 |

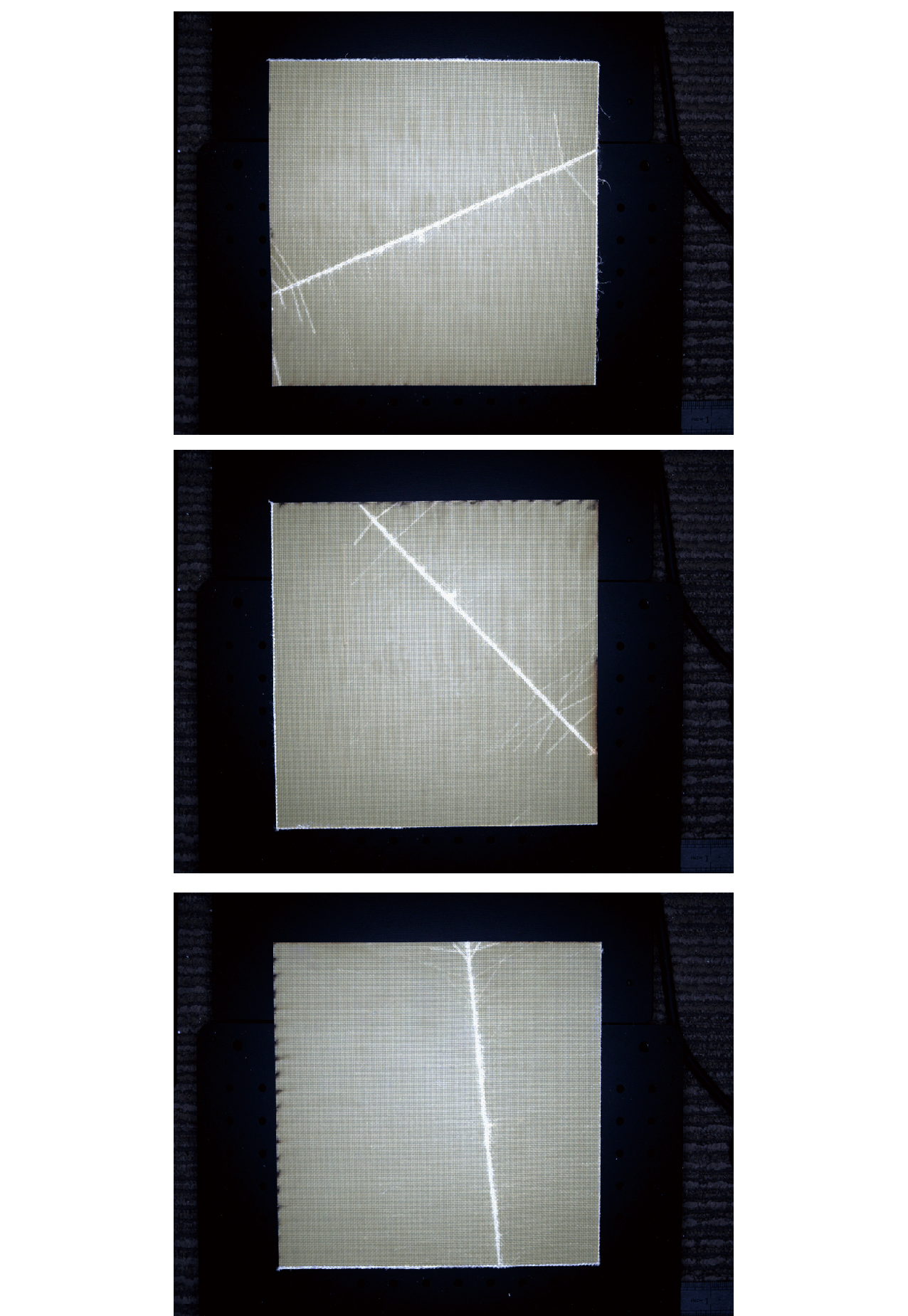

Fig.4 Images of protective material that produce bottom-left to top-right (upper), top-left to bottom-right (middle), and vertical (below) mechanical creases

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 二维卷积层 | 3 | 32 | 5×5 | 1024×1024 | |

| 1 | 二维卷积层 | 32 | 32 | 5×5 | 1024×1024 |

| 池化层 | 32 | 32 | 2×2 | 512×512 | |

| 二维卷积层 | 32 | 64 | 5×5 | 512×512 | |

| 2 | 二维卷积层 | 64 | 64 | 5×5 | 512×512 |

| 二维卷积层 | 64 | 64 | 5×5 | 512×512 | |

| 池化层 | 64 | 64 | 2×2 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 3 | 二维卷积层 | 64 | 64 | 5×5 | 256×256 |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 池化层 | 64 | 64 | 2×2 | 128×128 | |

| 注意力层 | 二维卷积层 | 64 | 4 | 1×1 | 128×128 |

| 二维卷积层 | 4 | 64 | 1×1 | 128×128 | |

| 4 | 二维卷积层 | 64 | 1024 | 15×15 | 128×128 |

| 5 | 二维卷积层 | 1024 | 1 | 1×1 | 128×128 |

Table 2 Major parameters of segmented network structure

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 二维卷积层 | 3 | 32 | 5×5 | 1024×1024 | |

| 1 | 二维卷积层 | 32 | 32 | 5×5 | 1024×1024 |

| 池化层 | 32 | 32 | 2×2 | 512×512 | |

| 二维卷积层 | 32 | 64 | 5×5 | 512×512 | |

| 2 | 二维卷积层 | 64 | 64 | 5×5 | 512×512 |

| 二维卷积层 | 64 | 64 | 5×5 | 512×512 | |

| 池化层 | 64 | 64 | 2×2 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 3 | 二维卷积层 | 64 | 64 | 5×5 | 256×256 |

| 二维卷积层 | 64 | 64 | 5×5 | 256×256 | |

| 池化层 | 64 | 64 | 2×2 | 128×128 | |

| 注意力层 | 二维卷积层 | 64 | 4 | 1×1 | 128×128 |

| 二维卷积层 | 4 | 64 | 1×1 | 128×128 | |

| 4 | 二维卷积层 | 64 | 1024 | 15×15 | 128×128 |

| 5 | 二维卷积层 | 1024 | 1 | 1×1 | 128×128 |

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 深度 可分离 卷积层 | 二维卷积层 | 1 025 | 1 025 | 5×5 | 128×128 |

| 二维卷积层 | 1 025 | 8 | 5×5 | 128×128 | |

| 池化层 | 8 | 8 | 2×2 | 64×64 | |

| 二维卷积层 | 8 | 8 | 5×5 | 64×64 | |

| 二维卷积层 | 8 | 16 | 5×5 | 64×64 | |

| 池化层 | 16 | 16 | 2×2 | 32×32 | |

| 二维卷积层 | 16 | 32 | 5×5 | 32×32 | |

| 1 | 线性层 | 66 | 1 | — | 1×1 |

Table 3 Major parameters of decision network structure

| 层 | 网络 | 输入 通道数 | 输出 通道数 | 核尺寸 | 图像 尺寸 |

|---|---|---|---|---|---|

| 深度 可分离 卷积层 | 二维卷积层 | 1 025 | 1 025 | 5×5 | 128×128 |

| 二维卷积层 | 1 025 | 8 | 5×5 | 128×128 | |

| 池化层 | 8 | 8 | 2×2 | 64×64 | |

| 二维卷积层 | 8 | 8 | 5×5 | 64×64 | |

| 二维卷积层 | 8 | 16 | 5×5 | 64×64 | |

| 池化层 | 16 | 16 | 2×2 | 32×32 | |

| 二维卷积层 | 16 | 32 | 5×5 | 32×32 | |

| 1 | 线性层 | 66 | 1 | — | 1×1 |

| 网络 | 学习率 | 权重衰减系数 | 单次训练样本数 |

|---|---|---|---|

| 分割网络 | 0.00002 | 0.5 | 2 |

| 决策网络 | 0.002 | 0.5 | 2 |

Table 4 Major parameters of training neural network

| 网络 | 学习率 | 权重衰减系数 | 单次训练样本数 |

|---|---|---|---|

| 分割网络 | 0.00002 | 0.5 | 2 |

| 决策网络 | 0.002 | 0.5 | 2 |

| 模型 | 准确 率/% | 查准 率/% | 召回 率/% | F1 值 | 图像处理帧率/ (帧·s-1) |

|---|---|---|---|---|---|

| Models_Original | 67.62 | 92.86 | 55.71 | 69.64 | 5.96 |

| Models_Depthwise | 87.62 | 95.97 | 85.00 | 90.15 | 7.47 |

| Models_Depthwise_SE | 96.19 | 100.00 | 94.29 | 97.06 | 6.06 |

| YOLOv5s | 84.60 | 82.60 | 84.00 | 83.28 | 46.95 |

Table 5 Comparison of the results of the models

| 模型 | 准确 率/% | 查准 率/% | 召回 率/% | F1 值 | 图像处理帧率/ (帧·s-1) |

|---|---|---|---|---|---|

| Models_Original | 67.62 | 92.86 | 55.71 | 69.64 | 5.96 |

| Models_Depthwise | 87.62 | 95.97 | 85.00 | 90.15 | 7.47 |

| Models_Depthwise_SE | 96.19 | 100.00 | 94.29 | 97.06 | 6.06 |

| YOLOv5s | 84.60 | 82.60 | 84.00 | 83.28 | 46.95 |

| [1] |

邱日祥, 韩启龙. 防刺服的现状与发展[J]. 装备发展, 2020(5):77-81.

|

|

|

|

| [2] |

冯浩, 汪泽幸, 何斌, 等. 防刺服的研究与发展现状[J]. 产业用纺织品, 2021, 39(2):8-13,17.

|

|

|

|

| [3] |

doi: 10.1007/s10845-014-0876-9 URL |

| [4] |

doi: 10.1109/ACCESS.2018.2868059 URL |

| [5] |

doi: 10.3390/app12136633 URL |

| [6] |

doi: 10.1007/s10845-008-0140-2 URL |

| [7] |

廖达海, 殷明帅, 罗宏斌, 等. 基于耦合去噪算法的航空发动机中Si3N4圆柱滚子表面缺陷的检测方法[J]. 兵工学报, 2022, 43(1):191-198.

|

|

|

|

| [8] |

张良安, 陈洋, 谢胜龙, 等. 基于机器视觉与深度学习的飞机防护栅裂纹检测系统[J]. 兵工学报, 2023, 44(2):507-516.

|

|

|

|

| [9] |

|

| [10] |

|

| [11] |

doi: 10.1007/s00170-020-05887-6 |

| [12] |

doi: 10.1007/s10845-018-1412-0 |

| [13] |

doi: 10.1080/17452759.2020.1832695 URL |

| [14] |

doi: 10.1126/science.1127647 pmid: 16873662 |

| [15] |

doi: 10.1145/3065386 URL |

| [16] |

|

| [17] |

张博尧, 冷雁冰. 基于YOLOv4网络模型的金属表面划痕检测[J]. 兵工学报, 2022, 43(增刊1):214-221.

|

|

doi: 10.12382/bgxb.2022.A011 |

|

| [18] |

|

| [19] |

doi: 10.1016/j.cirp.2016.04.072 URL |

| [20] |

|

| [21] |

doi: 10.1007/s11263-007-0090-8 URL |

| [22] |

doi: 10.1109/JPROC.2010.2050290 URL |

| [23] |

|

| [24] |

|

| [25] |

pmid: 16173190 |

| [26] |

|

| [27] |

doi: 10.1002/(ISSN)1099-131X URL |

| [28] |

|

| [29] |

|

| No related articles found! |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||