主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2024, Vol. 45 ›› Issue (S2): 293-304.doi: 10.12382/bgxb.2024.0931

收稿日期:2024-10-05

上线日期:2024-12-12

通讯作者:

MA Zhiwei, LI Yuan*( ), GUO Mingzhe, SUN Mou

), GUO Mingzhe, SUN Mou

Received:2024-10-05

Online:2024-12-12

摘要:

分析发爆体系的空气冲击波、破片、热辐射等燃爆效应及传播规律,以及受爆体系中人员、设备设施及其他燃烧爆炸品(以下简称燃爆品)能够承受的容许程度,介绍由密闭抗爆结构、人员掩体、防护屏障、安全距离等构成的燃爆品生产制造典型工程防护措施。结合工程实践经验,从节约土地资源、进一步平衡工程防护的有效性及经济合理性出发,提出需要持续深入研究完善不同场景燃烧爆炸效应量化评估方法、事故造成毁伤程度的量化评估方法及风险可接受准则、工程防护措施有效性量化评估及优化方法等三方面问题。

马志伟, 李园, 郭明哲, 孙谋. 燃烧爆炸品工程安全防护体系现状及问题分析[J]. 兵工学报, 2024, 45(S2): 293-304.

MA Zhiwei, LI Yuan, GUO Mingzhe, SUN Mou. Current Status and Issues of the Safety Protection System for the Production Systems Engineering of Burning Explosives[J]. Acta Armamentarii, 2024, 45(S2): 293-304.

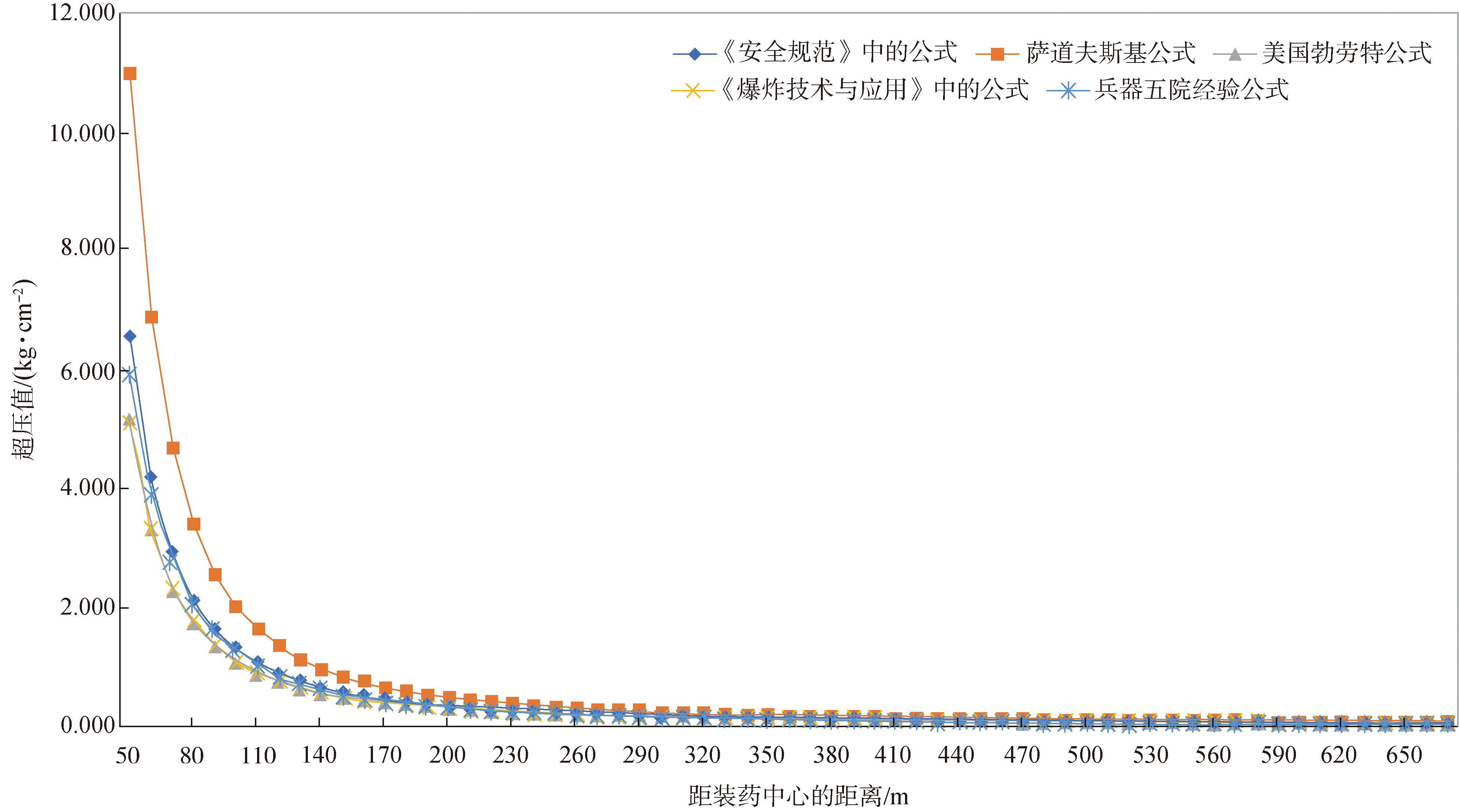

图2 不同公式计算空气冲击波超压随距离衰减情况对比图(以40000kgTNT当量为例)

Fig.2 Decays of air shock wave overpressure with distance in different formulas calculations (taking 40000kg TNT equivalent as an example)

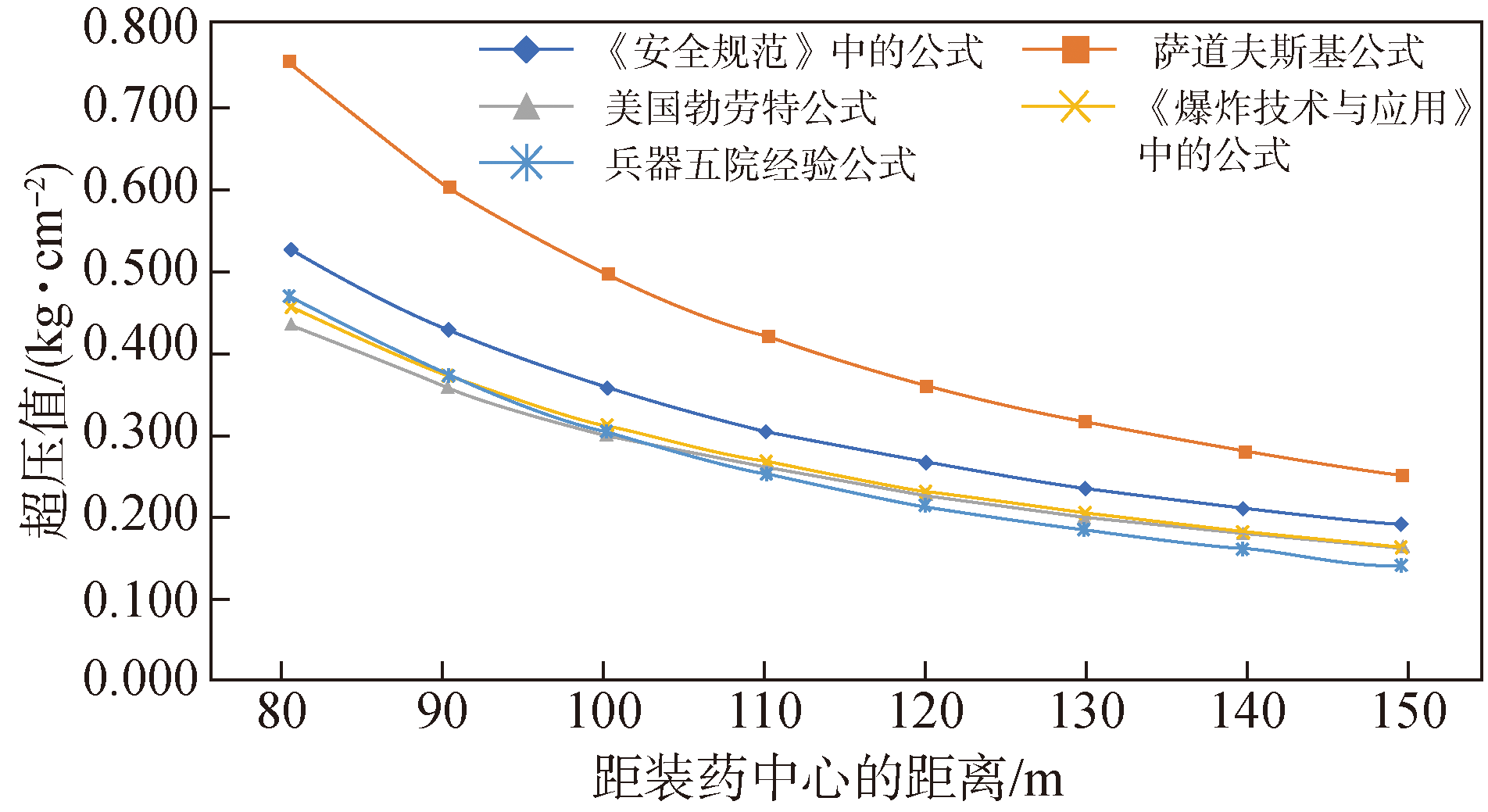

图3 不同公式计算空气冲击波超压随距离衰减情况对比图(以5000kg TNT当量为例)

Fig.3 Decays of air shock wave overpressure with distance in different formulas calculations(taking 5 000kg TNT equivalent as an example)

| 伤亡效应 | 空气冲击波超压Δp/(kg·cm-2) |

|---|---|

| 1%耳膜破裂 | 0.24 |

| 50%耳膜破裂 | 1.12 |

| 肺破裂界限 | 0.7(持续时间50ms), 1.4~2.1(持续时间3ms) |

| 1%的死亡 | 1.89(持续时间50ms), 4.2~2.14.9(持续时间3ms) |

表1 冲击波超压引发的伤亡效应

Table 1 Casualty effect caused by shock waveoverpressure

| 伤亡效应 | 空气冲击波超压Δp/(kg·cm-2) |

|---|---|

| 1%耳膜破裂 | 0.24 |

| 50%耳膜破裂 | 1.12 |

| 肺破裂界限 | 0.7(持续时间50ms), 1.4~2.1(持续时间3ms) |

| 1%的死亡 | 1.89(持续时间50ms), 4.2~2.14.9(持续时间3ms) |

| 人员损伤 程度 | 特征描述 | 空气冲击波超压 Δp/(kg·cm-2) |

|---|---|---|

| 轻微 | 轻微的挫伤 | 0.2~0.3 |

| 中等 | 听觉器官的损伤、中等挫伤、骨折等 | 0.3~0.5 |

| 严重 | 内脏严重挫伤,可引起死亡 | 0.5~1.0 |

| 极严重 | 可能大部分死亡 | >1.0 |

表2 冲击波超压引起人员损伤的特征

Table 2 Characteristics of person damage caused by shock wave overpressure

| 人员损伤 程度 | 特征描述 | 空气冲击波超压 Δp/(kg·cm-2) |

|---|---|---|

| 轻微 | 轻微的挫伤 | 0.2~0.3 |

| 中等 | 听觉器官的损伤、中等挫伤、骨折等 | 0.3~0.5 |

| 严重 | 内脏严重挫伤,可引起死亡 | 0.5~1.0 |

| 极严重 | 可能大部分死亡 | >1.0 |

| 热辐射强度/ (kW· ) | 对人员的伤害 |

|---|---|

| 37.5 | 1%死亡(10 s) 100%死亡(1min) |

| 25.0 | 重大烧伤(10s) 100%死亡(1min) |

| 12.5 | 1度烧伤(10s) 1%死亡(1min) |

| 6.3 | 在8s内裸露皮肤有痛感; 无热辐射屏蔽设施时,操作人员穿上防护服可停留1min |

| 4.7 | 暴露16s,裸露皮肤有痛感; 无热辐射屏蔽设施时,操作人员穿上防护服可停留几分钟 |

| 1.58 | 长时间暴露无不适感 |

表3 不同热辐射强度造成的人员伤害

Table 3 Injury to personnel caused by thermal radiation intensity

| 热辐射强度/ (kW· ) | 对人员的伤害 |

|---|---|

| 37.5 | 1%死亡(10 s) 100%死亡(1min) |

| 25.0 | 重大烧伤(10s) 100%死亡(1min) |

| 12.5 | 1度烧伤(10s) 1%死亡(1min) |

| 6.3 | 在8s内裸露皮肤有痛感; 无热辐射屏蔽设施时,操作人员穿上防护服可停留1min |

| 4.7 | 暴露16s,裸露皮肤有痛感; 无热辐射屏蔽设施时,操作人员穿上防护服可停留几分钟 |

| 1.58 | 长时间暴露无不适感 |

| 破坏等级及 其名称 | 超压Δp/(kg·cm-2) | |||||||

|---|---|---|---|---|---|---|---|---|

| <0.02 | 0.02~0.09 | 0.09~0.25 | 0.25~0.40 | 0.40~0.55 | 0.55~0.76 | >0.76 | ||

| 破坏等级 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| 破坏等级名称 | 基本无破坏 | 次轻度破坏 | 轻度破坏 | 中等破坏 | 次严重破坏 | 严重破坏 | 完全破坏 | |

表4 不同超压值对建筑物的破坏等级

Table 4 The damage levels of buildings under different overpressures

| 破坏等级及 其名称 | 超压Δp/(kg·cm-2) | |||||||

|---|---|---|---|---|---|---|---|---|

| <0.02 | 0.02~0.09 | 0.09~0.25 | 0.25~0.40 | 0.40~0.55 | 0.55~0.76 | >0.76 | ||

| 破坏等级 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| 破坏等级名称 | 基本无破坏 | 次轻度破坏 | 轻度破坏 | 中等破坏 | 次严重破坏 | 严重破坏 | 完全破坏 | |

| 建筑物 | 超压Δp/(kg·cm-2) | |||||||

|---|---|---|---|---|---|---|---|---|

| <0.02 | 0.02~0.09 | 0.09~0.25 | 0.25~0.40 | 0.40~0.55 | 0.55~0.76 | >0.76 | ||

| 玻璃 | 偶然破坏 | 少部分到大部分呈大块条状或小块破坏 | 大部分呈小块破坏到粉碎 | 粉碎 | ||||

| 木门窗 | 无损坏 | 窗扇少量破坏 | 窗扇大量破坏,窗框、门扇破坏 | 窗扇掉落、内倒、窗框、门扇大量破坏 | 门窗扇摧毁,窗框掉落 | |||

| 砖外墙 | 无损坏 | 无损坏 | 出现较小裂缝,宽度小于5mm,稍有倾斜 | 出现较大裂缝,缝宽5~50mm,明显倾斜,砖垛出现较小裂缝 | 出现大于50mm裂缝,严重倾斜,砖垛出现较大裂缝 | 部分倒塌 | 大部分到全部倒塌 | |

| 木屋盖 | 无损坏 | 无损坏 | 木屋面板变形,偶见折裂 | 木屋面板、木屋檩条折裂;木屋架支座松动 | 木檩条折断,木屋架杆件偶然折裂,支座错位 | 部分倒塌 | 全部倒塌 | |

| 瓦屋面 | 无损坏 | 无损坏 | 大量移动 | 大量移动到全部掀掉 | ||||

| 混凝土屋盖 | 无损坏 | 无损坏 | 无损坏 | 出现小于1mm的小裂缝 | 出现1~2mm宽的裂缝,修复后可继续使用 | 出现大于2mm的裂缝 | 承重砖墙大部分到全部倒塌,钢筋混凝土承重柱严重破坏 | |

| 顶棚 | 无损坏 | 抹灰少量掉落 | 抹灰大量掉落 | 木龙骨部分破坏、下垂缝 | 塌落 | |||

| 内墙 | 无损坏 | 板条墙抹灰小量掉落 | 板条墙抹灰大量掉落 | 砖内墙出现小裂缝 | 砖内墙出现大裂缝 | 砖内墙出现严重裂缝到部分倒塌 | 砖内墙大部倒塌 | |

| 混凝土柱 | 无损坏 | 无损坏 | 无损坏 | 无损坏 | 无损坏 | 有倾斜 | 有较大倾斜 | |

表5 不同超压值对建筑物的破坏影响

Table5 The damage effects of different overpressures on buildings

| 建筑物 | 超压Δp/(kg·cm-2) | |||||||

|---|---|---|---|---|---|---|---|---|

| <0.02 | 0.02~0.09 | 0.09~0.25 | 0.25~0.40 | 0.40~0.55 | 0.55~0.76 | >0.76 | ||

| 玻璃 | 偶然破坏 | 少部分到大部分呈大块条状或小块破坏 | 大部分呈小块破坏到粉碎 | 粉碎 | ||||

| 木门窗 | 无损坏 | 窗扇少量破坏 | 窗扇大量破坏,窗框、门扇破坏 | 窗扇掉落、内倒、窗框、门扇大量破坏 | 门窗扇摧毁,窗框掉落 | |||

| 砖外墙 | 无损坏 | 无损坏 | 出现较小裂缝,宽度小于5mm,稍有倾斜 | 出现较大裂缝,缝宽5~50mm,明显倾斜,砖垛出现较小裂缝 | 出现大于50mm裂缝,严重倾斜,砖垛出现较大裂缝 | 部分倒塌 | 大部分到全部倒塌 | |

| 木屋盖 | 无损坏 | 无损坏 | 木屋面板变形,偶见折裂 | 木屋面板、木屋檩条折裂;木屋架支座松动 | 木檩条折断,木屋架杆件偶然折裂,支座错位 | 部分倒塌 | 全部倒塌 | |

| 瓦屋面 | 无损坏 | 无损坏 | 大量移动 | 大量移动到全部掀掉 | ||||

| 混凝土屋盖 | 无损坏 | 无损坏 | 无损坏 | 出现小于1mm的小裂缝 | 出现1~2mm宽的裂缝,修复后可继续使用 | 出现大于2mm的裂缝 | 承重砖墙大部分到全部倒塌,钢筋混凝土承重柱严重破坏 | |

| 顶棚 | 无损坏 | 抹灰少量掉落 | 抹灰大量掉落 | 木龙骨部分破坏、下垂缝 | 塌落 | |||

| 内墙 | 无损坏 | 板条墙抹灰小量掉落 | 板条墙抹灰大量掉落 | 砖内墙出现小裂缝 | 砖内墙出现大裂缝 | 砖内墙出现严重裂缝到部分倒塌 | 砖内墙大部倒塌 | |

| 混凝土柱 | 无损坏 | 无损坏 | 无损坏 | 无损坏 | 无损坏 | 有倾斜 | 有较大倾斜 | |

| [1] |

董文学, 李春光, 魏新熙, 等. GF/T 8—2023.军工燃烧爆炸品工程设计安全规范[S]. 北京: 国家国防科技工业局, 2021.

|

|

|

|

| [2] |

杨科之, 刘盛. 空气冲击波传播和衰减研究进展[J]. 防护工程, 2020, 42(3):1-10.

|

|

|

|

| [3] |

黄广炎. 爆炸技术及应用[M]. 北京: 北京理工大学出版社, 2021: 297-298.

|

|

|

|

| [4] |

王浩喆. 爆炸事故中破片伤害准则综述[J]. 安全、健康和环境, 2022, 22(4):11-16.

|

|

|

|

| [5] |

陈新华. 液体推进剂火箭爆炸辐射效应研究[J]. 宇航学报, 1997, 18(1):80-85.

|

|

|

|

| [6] |

王艳平, 曾丹, 张同来, 等. 发射药燃烧热辐射传播规律[J]. 爆炸与冲击, 2018, 38(1):212-216.

|

|

|

|

| [7] |

赵志宁, 王辰. 新型弹药热辐射毁伤效应研究[J]. 军械工程学院学报, 2015, 27(1):15-18.

|

|

|

|

| [8] |

黄磊. 不同炸药爆源的爆炸场热效应分析与测试[D]. 南京: 南京理工大学, 2013: 8-11.

|

|

|

|

| [9] |

|

| [10] |

李铮. 空气冲击波作用下人安全距离[J]. 爆炸与冲击, 1990, 10(2):135-144.

|

|

|

|

| [11] |

王波, 杨剑波, 姚李刚, 等. 爆炸冲击波作用下人体肺部的损伤[J]. 爆炸与冲击, 2022, 42(12):122201.

|

|

|

|

| [12] |

周杰, 陶钢. 人体胸部爆炸冲击波创伤模型与评估[J]. 弹道学报, 2013, 25(3):64-69.

|

|

|

|

| [13] |

王新颖, 王树山, 卢熹, 等空中爆炸冲击波对生物目标的超压-冲量准则[J]. 爆炸与冲击, 2018, 38(1):106-110

|

|

|

|

| [14] |

Office of the Under Secretary of Defense for Acquisition and Sustainment. DESR 6055.09,Edition 1.Defense explosives safety regulation 6055.09[S]. Washington,D.C.,US: Department of Defense Explosives Safety Board, 2019.

|

| [15] |

孙业斌. 爆炸作用与装药设计[M]. 北京: 国防工业出版社, 1987: 95-96.

|

|

|

|

| [16] |

隋树元, 王树山. 终点效应学[M]. 北京: 国防工业出版社, 2000: 1-7.

|

|

|

|

| [17] |

王泽溥, 郑志良. 爆炸及其防护[M]. 北京: 兵器工业出版社, 2008:70.

|

|

|

|

| [18] |

王昕, 蒋建伟, 王树有, 等. 破片撞击起爆柱面带壳装药的临界速度修正判据[J]. 爆炸与冲击, 2019, 39(1):012302.

|

|

|

|

| [19] |

王泽溥, 郑志良. 爆炸及其防护[M]. 北京: 兵器工业出版社, 2008:217-219.

|

|

|

|

| [20] |

刘保华, 徐文龙, 王成, 等. 接触爆炸下聚脲涂层增强钢板的抗爆性能[J]. 兵工学报, 2024, 45(5):1637-1647

doi: 10.12382/bgxb.2023.0090 |

|

doi: 10.12382/bgxb.2023.0090 |

| [1] | 王付安, 赵媛媛, 孙琤, 吴斯琪, 郭进秋. 燃烧爆炸品生产设备危险性评价方法[J]. 兵工学报, 2024, 45(S1): 331-338. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4