主管单位:中国科学技术协会

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

主办单位:中国兵工学会

ISSN 1000-1093 CN 11-2176/TJ

兵工学报 ›› 2023, Vol. 44 ›› Issue (3): 691-701.doi: 10.12382/bgxb.2022.0618

许睿轩( ), 徐家兴(

), 徐家兴( ), 薛智华(

), 薛智华( ), 吕杰尧(

), 吕杰尧( ), 严启龙(

), 严启龙( )

)

收稿日期:2022-07-08

上线日期:2022-09-08

作者简介: |

许睿轩(1995—),男,博士研究生,研究方向为铝基复合燃料制备及固体推进剂燃烧性能。E-mail:ruixuanxu@mail.nwpu.edu.cn; |

|

徐家兴(1995—),男,硕士研究生,研究方向为含能复合物制备及固体复合推进剂的力学性能。E-mail:923094207@qq.com; |

|

薛智华(1997—),女,博士研究生,研究方向为含能材料的高能钝感化改性。E-mail:zhihuaxue@mail.nwpu.edu.cn; |

|

吕杰尧(1996—),男,硕士研究生,研究方向为含能材料的设计与燃烧性能。E-mail:jieyaolyu@gmail.com |

基金资助:

XU Ruixuan( ), XU Jiaxing(

), XU Jiaxing( ), XUE Zhihua(

), XUE Zhihua( ), LÜ Jieyao(

), LÜ Jieyao( ), YAN Qilong(

), YAN Qilong( )

)

Received:2022-07-08

Online:2022-09-08

摘要:

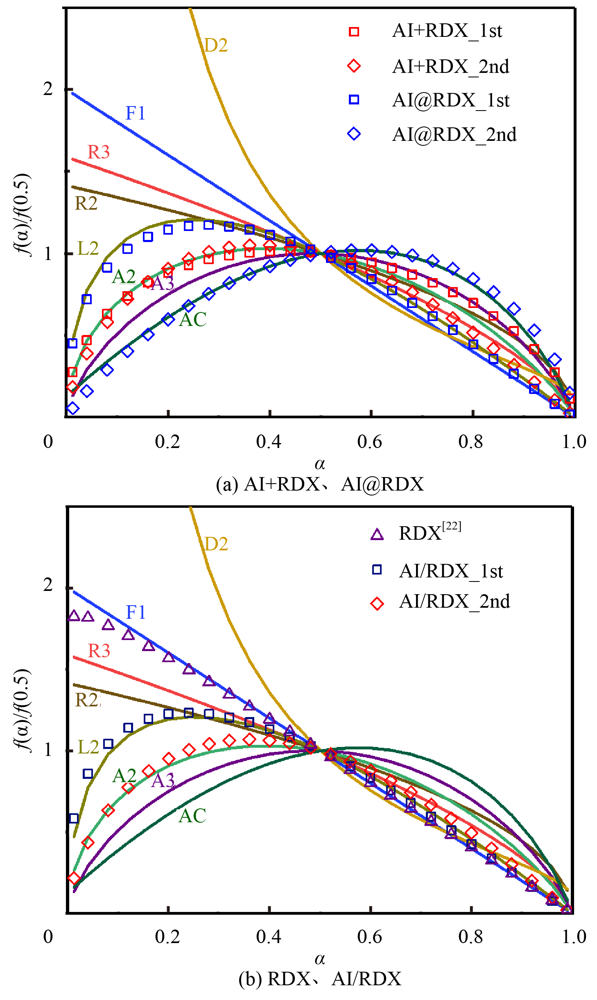

基于氧化剂/燃料一体化设计理念,在对Al颗粒进行表面修饰的基础上,采用声共振和喷雾干燥技术成功制得了多尺度界面可调半嵌入型Al/RDX和全嵌入型Al@RDX复合颗粒。通过扫描电子显微镜(SEM)等技术对复合颗粒的形貌、密度和燃烧热进行表征,并利用热红同步热分析仪(DSC-TG-FT-IR)对其热分解过程及气相产物进行了研究。研究结果表明:与机械混合物相比,复合颗粒密度基本保持不变,但燃烧热分别提升至17.31 kJ/g和18.82 kJ/g. DSC结果表明两种方式均可提高RDX的热分解放热量:铝粉嵌入未改变RDX的气相分解产物种类,但其中HCHO的相对含量有所增加:嵌入铝粉后RDX第一分解阶段均由二维成核增长模型(A2)转变为链断裂模型(L2):全嵌入型Al@RDX的第二分解阶段则转变为自催化模型(AC)。

许睿轩, 徐家兴, 薛智华, 吕杰尧, 严启龙. 多尺度界面可调型Al-RDX含能复合物的制备及其热分解特性[J]. 兵工学报, 2023, 44(3): 691-701.

XU Ruixuan, XU Jiaxing, XUE Zhihua, LÜ Jieyao, YAN Qilong. Preparation and Thermal Decomposition Properties of Multi-scale Interface-Tunable Al/RDX Energetic Composites[J]. Acta Armamentarii, 2023, 44(3): 691-701.

| 样品 | 真密度 /(g·cm-3) | 单位质量燃烧热/(kJ·g-1) | ||||

|---|---|---|---|---|---|---|

| 第1次 | 第2次 | 第3次 | 平均值 | 标准差 | ||

| RDX | 1.82 | 9.40 | 9.81 | 9.47 | 9.56 | 0.22 |

| Al+RDX | 2.25 | 16.84 | 16.44 | 16.98 | 16.75 | 0.28 |

| Al/RDX | 2.25 | 17.30 | 17.45 | 17.17 | 17.31 | 0.14 |

| Al@RDX | 2.26 | 19.20 | 18.57 | 18.69 | 18.82 | 0.33 |

表1 样品的密度和燃烧热测试结果

Table1 Results of the true density and heat of combustion of RDX and the composites with different structures

| 样品 | 真密度 /(g·cm-3) | 单位质量燃烧热/(kJ·g-1) | ||||

|---|---|---|---|---|---|---|

| 第1次 | 第2次 | 第3次 | 平均值 | 标准差 | ||

| RDX | 1.82 | 9.40 | 9.81 | 9.47 | 9.56 | 0.22 |

| Al+RDX | 2.25 | 16.84 | 16.44 | 16.98 | 16.75 | 0.28 |

| Al/RDX | 2.25 | 17.30 | 17.45 | 17.17 | 17.31 | 0.14 |

| Al@RDX | 2.26 | 19.20 | 18.57 | 18.69 | 18.82 | 0.33 |

| 样品 | Tm/°C | Ti/°C | Tp/°C | Te/°C | W/°C | △H/(J·g-1) |

|---|---|---|---|---|---|---|

| RDX[ | 205.1 | 226.7 | 248.7 | 255.7 | 29.0 | 1 747.0 |

| RDX[ | 204.1 | 242.3 | 1 812.0 | |||

| Al+RDX | 205.3 | 227.4 | 247.7 | 254.7 | 24.8 | 771.2 |

| Al/RDX | 189.4 | 228.4 | 251.8 | 278.6 | 40.0 | 779.4 |

| Al@RDX | 205.3 | 223.8 | 243.0 | 257.4 | 30.9 | 775.2 |

表2 RDX、Al+RDX、Al/RDX和Al@RDX复合颗粒热分解过程DSC特征参数

Table 2 DSC characteristic parameters of RDX, Al+RDX, Al/RDX and Al@RDX composites

| 样品 | Tm/°C | Ti/°C | Tp/°C | Te/°C | W/°C | △H/(J·g-1) |

|---|---|---|---|---|---|---|

| RDX[ | 205.1 | 226.7 | 248.7 | 255.7 | 29.0 | 1 747.0 |

| RDX[ | 204.1 | 242.3 | 1 812.0 | |||

| Al+RDX | 205.3 | 227.4 | 247.7 | 254.7 | 24.8 | 771.2 |

| Al/RDX | 189.4 | 228.4 | 251.8 | 278.6 | 40.0 | 779.4 |

| Al@RDX | 205.3 | 223.8 | 243.0 | 257.4 | 30.9 | 775.2 |

| 样品 | 阶段 | 联合动力学法 | Friedman法 | Kissinger法 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| m | n | Ea(1) | cA/min−1 | Ea(2) | r | Ea(3) | Log A | r | ||

| RDX[ | 196.5 | 13.79 | 0.998 5 | |||||||

| RDX[ | 0.021 | 0.997 | 159.6±0.7 | 3.7×1015 | 246.2 | 130.4 | 11.87 | 0.995 0 | ||

| RDX/TAG-Ni[ | 0.135 | 0.944 | 189.4±1.2 | 1.2×1017 | 192.2 | 0.995 4 | 186.5 | 13.18 | ||

| RDX/TAG-Co[ | 0.090 | 0.891 | 203.6±2.3 | 2.8×1018 | 156.7 | 0.999 9 | 195.3 | 14.02 | ||

| Al+RDX | 1st | 0.461 | 0.631 | 153.0±0.7 | 4.5×1014 | 151.5 | 0.998 5 | 163.0 | 10.81 | 0.995 5 |

| 2nd | 0.646 | 1.053 | 58.2±2.4 | 5.2×1004 | 16.0 | 0.995 3 | 144.7 | 8.70 | 0.992 7 | |

| Al/RDX | 1st | 0.347 | 1.109 | 152.0±2.3 | 1.4×1014 | 156.1 | 0.993 7 | 136.0 | 7.77 | 0.998 6 |

| 2nd | 0.606 | 1.076 | 148.8±2.1 | 8.4×1012 | 151.2 | 0.996 0 | 192.8 | 12.85 | 0.980 9 | |

| Al@RDX | 1st | 0.413 | 1.093 | 155.0±1.6 | 8.7×1014 | 150.5 | 0.989 3 | 137.1 | 8.22 | 0.999 9 |

| 2nd | 0.890 | 0.641 | 31.1±0.3 | 5.4×1001 | 29.4 | 0.994 4 | 155.6 | 9.85 | 0.999 0 | |

表3 RDX、Al+RDX、Al/RDX和Al@RDX复合颗粒的热分解动力学参数

Table 3 Thermal decomposition kinetic parameters of RDX, Al+RDX, Al/RDX and Al@RDX composites

| 样品 | 阶段 | 联合动力学法 | Friedman法 | Kissinger法 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| m | n | Ea(1) | cA/min−1 | Ea(2) | r | Ea(3) | Log A | r | ||

| RDX[ | 196.5 | 13.79 | 0.998 5 | |||||||

| RDX[ | 0.021 | 0.997 | 159.6±0.7 | 3.7×1015 | 246.2 | 130.4 | 11.87 | 0.995 0 | ||

| RDX/TAG-Ni[ | 0.135 | 0.944 | 189.4±1.2 | 1.2×1017 | 192.2 | 0.995 4 | 186.5 | 13.18 | ||

| RDX/TAG-Co[ | 0.090 | 0.891 | 203.6±2.3 | 2.8×1018 | 156.7 | 0.999 9 | 195.3 | 14.02 | ||

| Al+RDX | 1st | 0.461 | 0.631 | 153.0±0.7 | 4.5×1014 | 151.5 | 0.998 5 | 163.0 | 10.81 | 0.995 5 |

| 2nd | 0.646 | 1.053 | 58.2±2.4 | 5.2×1004 | 16.0 | 0.995 3 | 144.7 | 8.70 | 0.992 7 | |

| Al/RDX | 1st | 0.347 | 1.109 | 152.0±2.3 | 1.4×1014 | 156.1 | 0.993 7 | 136.0 | 7.77 | 0.998 6 |

| 2nd | 0.606 | 1.076 | 148.8±2.1 | 8.4×1012 | 151.2 | 0.996 0 | 192.8 | 12.85 | 0.980 9 | |

| Al@RDX | 1st | 0.413 | 1.093 | 155.0±1.6 | 8.7×1014 | 150.5 | 0.989 3 | 137.1 | 8.22 | 0.999 9 |

| 2nd | 0.890 | 0.641 | 31.1±0.3 | 5.4×1001 | 29.4 | 0.994 4 | 155.6 | 9.85 | 0.999 0 | |

图7 机械混合物Al+RDX、半嵌入型Al/RDX和全嵌入型Al@RDX复合颗粒的热分解气相产物FT-IR图

Fig. 7 FT-IR results of the gas phase decomposition products of Al+RDX, Al/RDX and Al@RDX composites

图9 联合动力学法计算的RDX、Al+RDX、Al/RDX和Al@RDX复合颗粒热分解动力学模型(D2:二维扩散模型;F1:随机成核后一维核生长模型;R2:收缩模型;R3:相界面收缩模型;L2:链断裂模型;A2:随机成核后二维核生长模型;A3:随机成核后二维核生长模型;AC:自催化模型)

Fig. 9 Comparison of the normalized curves for the decomposition kinetic models of RDX、Al+RDX、 Al/RDX and Al@RDX composites obtained by the combined kinetic method (D2, two-dimensional diffusion model; F1, first order reaction, so-called unimolecular decay law, where random nucleation is followed by an instantaneous growth of nuclei; R2, phase boundary controlled reaction (contracting area), R3, phase boundary controlled reaction (contracting volume); L2, random chain scission model; A2 and A3, random two and three dimensional nucleation and nucleus growth models; AC, autocatalytic model.)

| [1] |

谭惠民. 固体推进剂化学与技术[M]. 北京: 北京理工大学出版社, 2015.

|

|

|

|

| [2] |

|

| [3] |

|

| [4] |

刘晶如, 罗运军. 固体推进剂用金属燃烧剂的研究及应用[J]. 化学推进剂与高分子材料, 2007(4): 6-12.

|

|

|

|

| [5] |

肖立群, 樊学忠, 王晗, 等. 含铝固体推进剂燃烧过程中铝粉团聚现象研究进展[J]. 火炸药学报, 2018, 41(1):7-15, 25.

|

|

|

|

| [6] |

|

| [7] |

|

| [8] |

唐泉, 庞爱民, 汪越. 固体推进剂铝粉燃烧特性及机理研究进展分析[J]. 固体火箭技术, 2015, 38(2): 232-238

|

|

|

|

| [9] |

敖文, 刘佩进, 吕翔, 等. 固体推进剂燃烧过程铝团聚研究进展[J]. 宇航学报, 2016, 37(4): 371-380.

|

|

|

|

| [10] |

庞维强,

|

|

|

|

| [11] |

何伟. 反应界面调控型铝基复合燃料的制备及应用研究[D]. 西安: 西北工业大学, 2020.

|

|

|

|

| [12] |

doi: 10.1002/adma.v30.41 URL |

| [13] |

doi: 10.1016/j.cej.2019.122623 URL |

| [14] |

doi: 10.1016/j.cej.2020.124320 URL |

| [15] |

doi: 10.1016/j.combustflame.2022.112029 URL |

| [16] |

doi: 10.1016/j.fpc.2022.03.005 URL |

| [17] |

张光全, 刘晓波. 声共振混合技术在含能材料领域的应用进展[J]. 含能材料, 2021, 29(7): 680-686.

|

|

|

|

| [18] |

doi: 10.1016/j.cej.2019.03.165 URL |

| [19] |

doi: 10.1016/j.jhazmat.2020.122842 URL |

| [20] |

冯晓军, 薛乐星, 冯博, 等. “外嵌内包”微结构的奥克托今/铝复合粒子制备及其应用性能[J]. 兵工学报, 2021, 42(8): 1631-1637.

doi: 10.3969/j.issn.1000-1093.2021.08.007 |

|

|

|

| [21] |

doi: 10.1021/acs.jpcc.8b04355 URL |

| [22] |

doi: 10.1016/j.jhazmat.2014.02.019 URL |

| [23] |

doi: 10.1002/prep.v44.4 URL |

| [24] |

doi: 10.1080/07370652.2012.688788 URL |

| [25] |

doi: 10.1016/0010-2180(85)90147-6 URL |

| [26] |

崔厚欣. 吸收光谱法在实际应用中的关键问题的研究[D]. 天津: 天津大学, 2007.

|

|

|

|

| [27] |

doi: 10.1016/0010-2180(91)90149-6 URL |

| [28] |

刘子如, 刘艳, 范夕萍, 等. RDX和HMX的热分解III. 分解机理[J]. 火炸药学报, 2006, 29(4): 14-18.

|

|

|

|

| [29] |

doi: 10.1021/jp064792g URL |

| [30] |

doi: 10.1149/1.3551496 URL |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备11010802024360号 京ICP备05059581号-4

京公网安备11010802024360号 京ICP备05059581号-4