Responsible Institution: China Association for Science and Technology

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Sponsor: China Ordnance Society

ISSN 1000-1093 CN 11-2176/TJ

Acta Armamentarii ›› 2025, Vol. 46 ›› Issue (10): 250110-.doi: 10.12382/bgxb.2025.0110

Previous Articles Next Articles

ZHANG Wenwen1,2, ZHAO Dan1,2,*( ), ZHAO Weitao1,2, WANG Qiang3, WANG Jianjun1,2, MA Shengguo1,2, ZHANG Tuanwei1,2, WANG Zhihua1,2

), ZHAO Weitao1,2, WANG Qiang3, WANG Jianjun1,2, MA Shengguo1,2, ZHANG Tuanwei1,2, WANG Zhihua1,2

Received:2025-02-21

Online:2025-11-05

Contact:

ZHAO Dan

CLC Number:

ZHANG Wenwen, ZHAO Dan, ZHAO Weitao, WANG Qiang, WANG Jianjun, MA Shengguo, ZHANG Tuanwei, WANG Zhihua. Crystal Plasticity Model of Precipitation Strengthening of CoCrNi-based High-entropy Alloys: Mechanical Properties and Texture Evolution[J]. Acta Armamentarii, 2025, 46(10): 250110-.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| ${C}_{11}^{matrix}$/GPa | 245 | α | 0.0008 |

| ${C}_{11}^{1}$/GPa | 477 | ${\tau }_{0}^{1}$/MPa | 183 |

| m | 10 | r2/nm | 500 |

| ${h}_{0}^{2}$/MPa | 51 | f3 | 0.1 |

| μ1,μ2/GPa | 299 | ${C}_{44}^{matrix}$/GPa | 142 |

| τ0/MPa | 92.7 | ${C}_{44}^{1}$/GPa | 137 |

| b2, b3/nm | 0.43 | h0/MPa | 51 |

| f2 | 0.1 | APB2,APB3/(J·m-2) | 0.5 |

| ${C}_{12}^{matrix}$/GPa | 156 | β | 0.143 |

| ${C}_{12}^{1}$/GPa | 198 | τs/MPa | 215 |

| ${\stackrel{·}{\gamma }}_{0}$/s-1 | 0.001 | r3/nm | 50 |

| ${\tau }_{s}^{1}$/MPa | 1150 |

Table 1 CoCrNiSi0.3C0.048 crystal plastic model related parameters

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| ${C}_{11}^{matrix}$/GPa | 245 | α | 0.0008 |

| ${C}_{11}^{1}$/GPa | 477 | ${\tau }_{0}^{1}$/MPa | 183 |

| m | 10 | r2/nm | 500 |

| ${h}_{0}^{2}$/MPa | 51 | f3 | 0.1 |

| μ1,μ2/GPa | 299 | ${C}_{44}^{matrix}$/GPa | 142 |

| τ0/MPa | 92.7 | ${C}_{44}^{1}$/GPa | 137 |

| b2, b3/nm | 0.43 | h0/MPa | 51 |

| f2 | 0.1 | APB2,APB3/(J·m-2) | 0.5 |

| ${C}_{12}^{matrix}$/GPa | 156 | β | 0.143 |

| ${C}_{12}^{1}$/GPa | 198 | τs/MPa | 215 |

| ${\stackrel{·}{\gamma }}_{0}$/s-1 | 0.001 | r3/nm | 50 |

| ${\tau }_{s}^{1}$/MPa | 1150 |

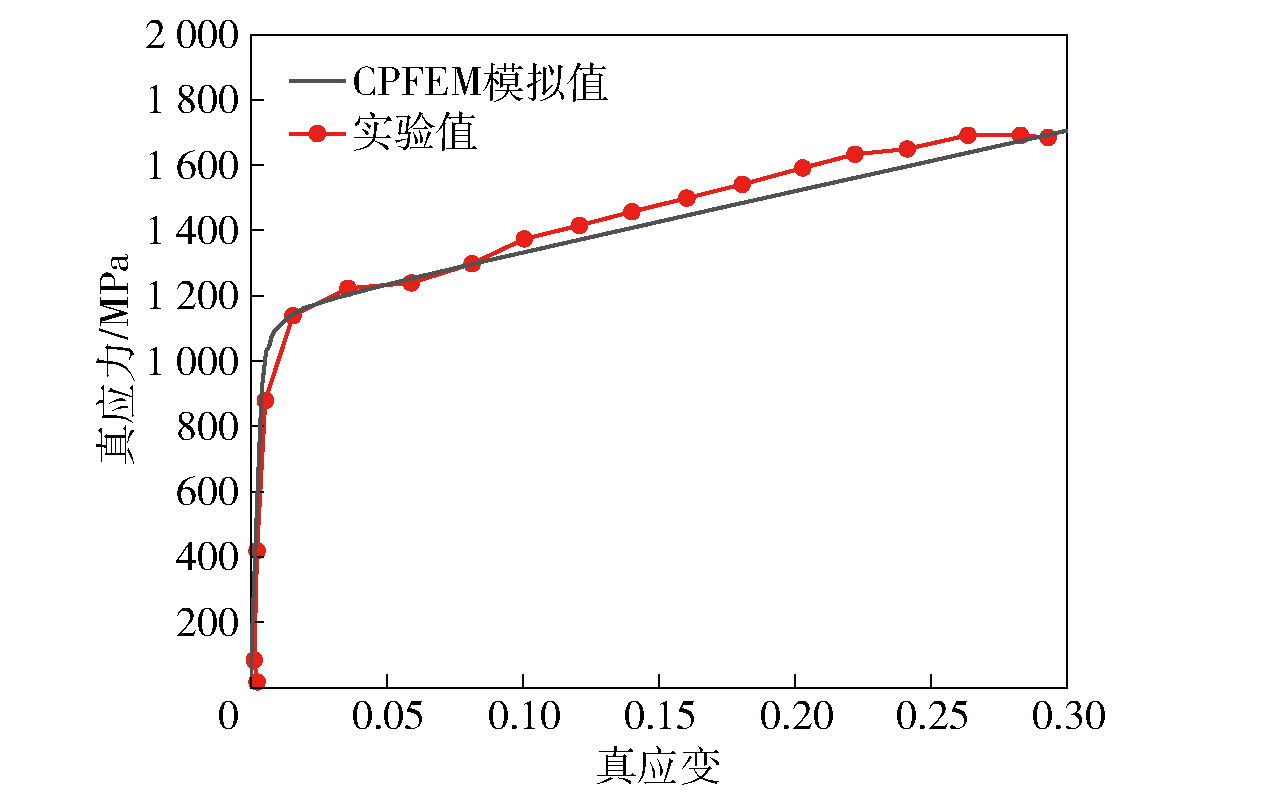

Fig.6 The dynamic compression experiment of CoCrNiSi0.3C0.048 at $\stackrel{·}{\epsilon }$= 3000s-1 and the mechanical response of CPFEM simulation results

| [1] |

doi: 10.1002/adem.v6:5 URL |

| [2] |

doi: 10.1016/j.pmatsci.2023.101106 URL |

| [3] |

doi: 10.1038/s41467-023-35863-z pmid: 36627295 |

| [4] |

doi: 10.1016/j.jmrt.2024.01.149 URL |

| [5] |

王伟彤, 陈淑英, 张勇, 等. 高熵合金强韧化方法及力学性能的研究进展[J]. 材料导报, 2021, 35(17): 17043-17050.

|

|

|

|

| [6] |

doi: 10.1016/j.jmrt.2024.03.005 URL |

| [7] |

doi: 10.1016/j.matdes.2004.09.027 URL |

| [8] |

|

| [9] |

|

| [10] |

doi: 10.1080/02670836.2021.2003613 URL |

| [11] |

doi: 10.1016/j.ijplas.2020.102759 URL |

| [12] |

doi: 10.1007/s43452-023-00696-6 |

| [13] |

徐笑, 樊黎霞, 王亚平, 等. 身管精锻过程跨尺度多晶体塑性有限元模拟与织构预测[J]. 兵工学报, 2016, 37(7): 1180-1186.

doi: 10.3969/j.issn.1000-1093.2016.07.004 |

|

doi: 10.3969/j.issn.1000-1093.2016.07.004 |

|

| [14] |

|

| [15] |

王强, 张团卫, 王建军, 等. 高速Taylor冲击下CoCrNiSi0.3C0.048中熵合金变形微观结构的演变机制[J]. 固体力学学报, 2023, 44(6): 755-770.

|

|

|

|

| [16] |

|

| [17] |

|

| [18] |

doi: 10.1098/rspa.1976.0027 URL |

| [19] |

|

| [20] |

doi: 10.1088/0959-5309/52/1/303 URL |

| [21] |

张宇恒. 搓捻成形晶体塑性有限元模拟与试验研究[D]. 长春: 吉林大学, 2021.

|

|

|

|

| [22] |

doi: 10.1016/j.jmrt.2024.04.245 URL |

| [23] |

|

| [24] |

doi: 10.1016/j.jallcom.2011.02.009 URL |

| [25] |

doi: 10.1016/0955-2219(95)00199-9 URL |

| [26] |

doi: 10.1143/APEX.5.081301 URL |

| [27] |

|

| [28] |

|

| [29] |

doi: 10.1016/j.jallcom.2016.08.322 URL |

| [30] |

doi: 10.1016/0001-6160(88)90173-3 URL |

| [31] |

刘彪, 宋新莉, 朱瑞琪, 等. Nb对低温取向硅钢高斯织构演变的影响[J]. 材料热处理学报, 2017, 38 (11): 71-79.

|

|

|

| [1] | WANG Shengfang, CHANG Hui, JIAO Zhiming, YIN Yunfei, ZHANG Tuanwei, LI Zhiqiang, WANG Zhihua. Study on the Damage Effect and Debris Cloud Characteristics of Reactive Fragments of High-entropy Alloys [J]. Acta Armamentarii, 2025, 46(10): 250482-. |

| [2] | LING Jing, LIANG Yanxiang, JING Lin. Dynamic Impact Mechanics Response and Deformation Mechanisms of Al15(CoCrFeNi)85 High-entropy Alloy [J]. Acta Armamentarii, 2025, 46(10): 250499-. |

| [3] | LIU Zichang, LI Siyu, PEI Mochao, LIU Jie, MENG Shuo, WU Weiyi. Fault Diagnosis Method for Diesel Engine Based on Texture Analysis [J]. Acta Armamentarii, 2024, 45(2): 684-694. |

| [4] | LI Zhonghua, YU Jun, HU Zhiyi, KANG Qinyu, GAO Shouyi, LIAN Zhichao, XIAO Feng. A method of Stitching Digital Camouflage Patterns on Different Planes Based on Texture Synthesis and Best Seam Line Algorithm [J]. Acta Armamentarii, 2019, 40(3): 666-672. |

| [5] | RAO Xiang, SHENG Chen-xing, GUO Zhi-wei. Research on the Friction and Wear Properties of Diesel Engine Cylinder Liner with Different Surface Textures [J]. Acta Armamentarii, 2018, 39(2): 356-363. |

| [6] | XU Xiao, FAN Li-xia, WANG Ya-ping, DONG Xiao-bin. Trans-scale Polycrystalline Finite Element Simulation of Radial Forging Process for Barrel and Prediction of Texture [J]. Acta Armamentarii, 2016, 37(7): 1180-1186. |

| [7] | TIAN Xin-li, WANG Long, WANG Wang-long, TANG Xiu-jian, WU Zhi-yuan. Analysis of Surface Texture of Push-processed Si3N4 Ceramics Based on Gray Level Co-occurrence Matrix and Neural Network [J]. Acta Armamentarii, 2015, 36(8): 1518-1524. |

| [8] | QI Ye, CHANG Qiu-ying, WANG Bin, LI Juan. Research on Tribological Behaviors of Laser Surface Textures under Dry Sliding [J]. Acta Armamentarii, 2015, 36(2): 200-205. |

| [9] | DONG Xin-long, FU Ying-qian. Experimental and Numerical Study of Adiabatic Shear Failure of TA2 Titanium Alloy under Dynamic Compression [J]. Acta Armamentarii, 2014, 35(7): 1016-1020. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||